Lentivirus production method

A production method and lentivirus technology, applied in biochemical equipment and methods, viruses/phages, microorganisms, etc., can solve the problems of unsuitability for large-scale production of lentiviruses, unstable temperature of ultracentrifuges, and low recovery rates. The effect of increasing the amount of poison, optimizing the packaging ratio, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

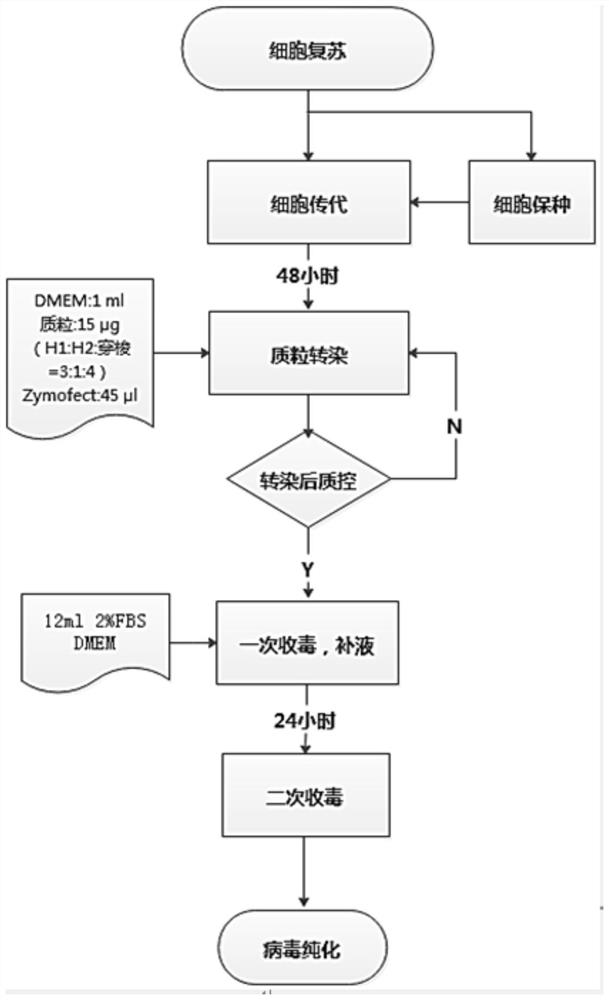

[0070] Example 1 Optimization of packaging conditions for transfection reagent Zymofect

[0071] The Zymofect 293 transfection reagent virus packaging process is as follows:

[0072] 1) Preparation before transfection: Add DMEM: 1 ml, H1 plasmid: 5.6 μg, H2 plasmid: 1.9 μg, shuttle plasmid (containing the target gene): 7.5 μg, Zymofect: 45 μl according to the amount of cells in each dish to calculate the required reagents volume of.

[0073] 2) Preparation of transfection system: Take a 50ml centrifuge tube, add the corresponding volumes of DMEM, H1 plasmid, H2 plasmid, and shuttle plasmid according to the amount calculated in step 1. After shaking and mixing, add the corresponding volume of Zymofect, and then centrifuge upside down. Tube 10-20 times, mix the transfection solution evenly, and place at room temperature for 5 min.

[0074] 3) Transfection: When the transfection solution is placed for 5 minutes, according to the amount of 1ml / dish, the transfection solution is ...

Embodiment 2 3

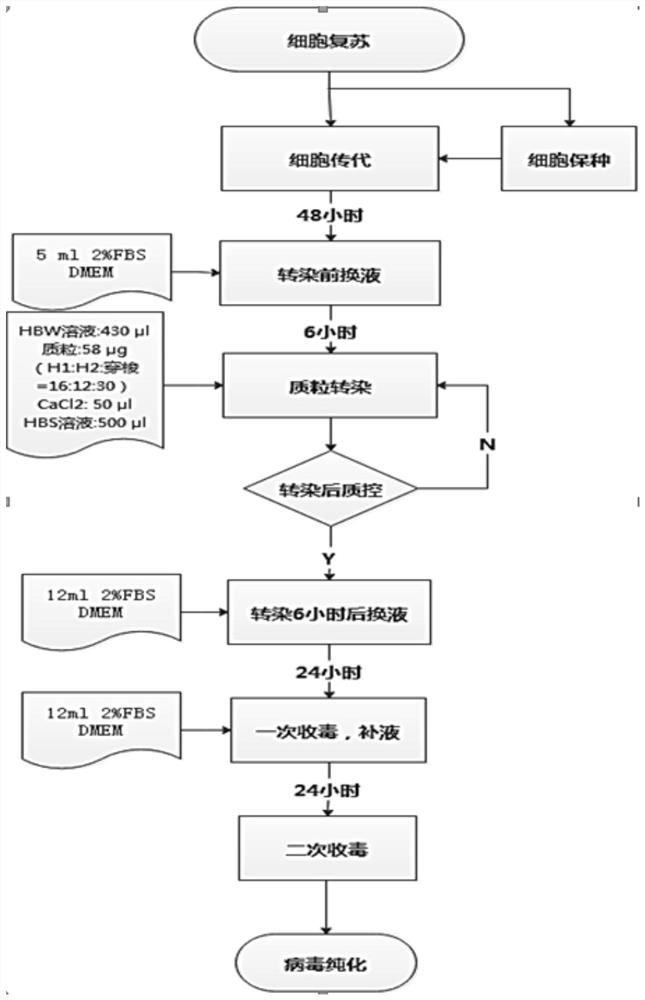

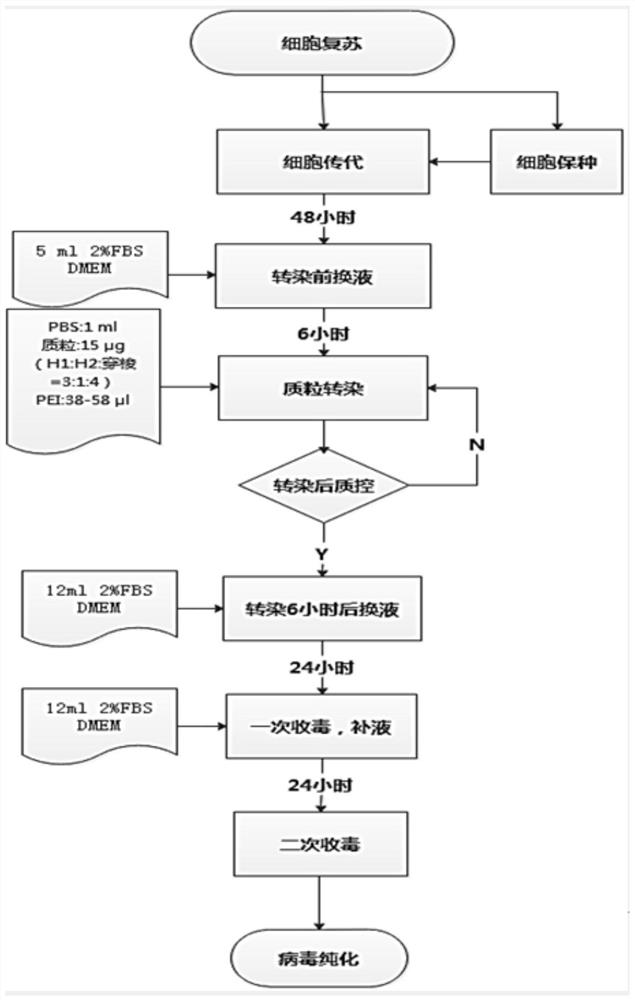

[0105] Example 2 Comparison of three packaging methods

[0106] 1. Comparison of stability and toxicity

[0107] The PEI packaging method is as follows:

[0108] 1) Preparation of transfection solution: Calculate the volume of reagents required to be added according to the amount of PBS: 1 ml, H1 plasmid: 5.6 μg, H2 plasmid: 1.9 μg, shuttle plasmid: 7.5 μg, and PEI reagent: 58 μl required for each dish of cells. Take out the corresponding number of cell culture dishes that have been cultured for about 48 hours in the cell incubator. The cells to be transfected with a cell confluence of 80%-85% are replaced with 5ml of DMEM medium with 2% FBS. After the medium change is completed, put the cells back 37°C incubator for use.

[0109] 2) Preparation of transfection solution: Take a 50ml centrifuge tube, add the corresponding volumes of PBS, H1 plasmid, H2 plasmid, and shuttle plasmid according to the amount calculated in step 1. After shaking and mixing, add the corresponding vo...

Embodiment 3

[0136] Embodiment 3 Purification mode condition exploration and optimization

[0137] 1. Pre-purification treatment

[0138] The collected lentiviral supernatant was passed through a 0.45 μm PES filter or 2000 rpm, and centrifuged at 4°C for 10 min before treatment.

[0139] The result is as Figure 15 and Figure 16 As shown, compared with the recovery rate of centrifugation and 0.45Hm filter, the recovery rate of 0.45μm filter is higher than that of centrifugation.

[0140] 2. Comparison of recovery rate between PEG concentration and purification method and ultra-ionization method

[0141] Virus concentration and purification by ultracentrifugation:

[0142] 1) Filtration: In the ultra-clean workbench, pass the collected lentivirus supernatant through a 0.45 μm PES filter membrane, and filter it into an ultra-centrifugation tube (Backman, Type 50.2 Ti or Type 45 Ti rotor with labeled lentivirus information) The supernatant volume in the supernatant tube should not be to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com