Rheological evaluation method for internal phase stability of ultra-high performance concrete

A technology of ultra-high performance and evaluation method, which is applied in the direction of material inspection products, design optimization/simulation, etc., can solve the problems of high detection cost, irreversible damage of materials, long test cycle, etc., and achieve the effect of short evaluation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

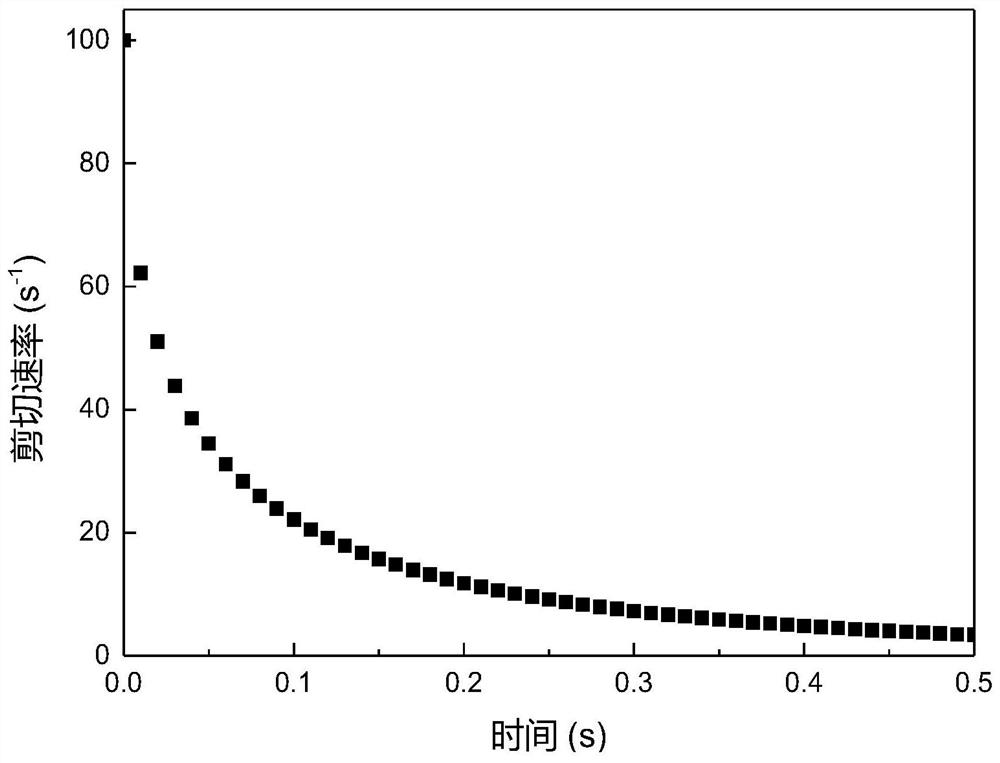

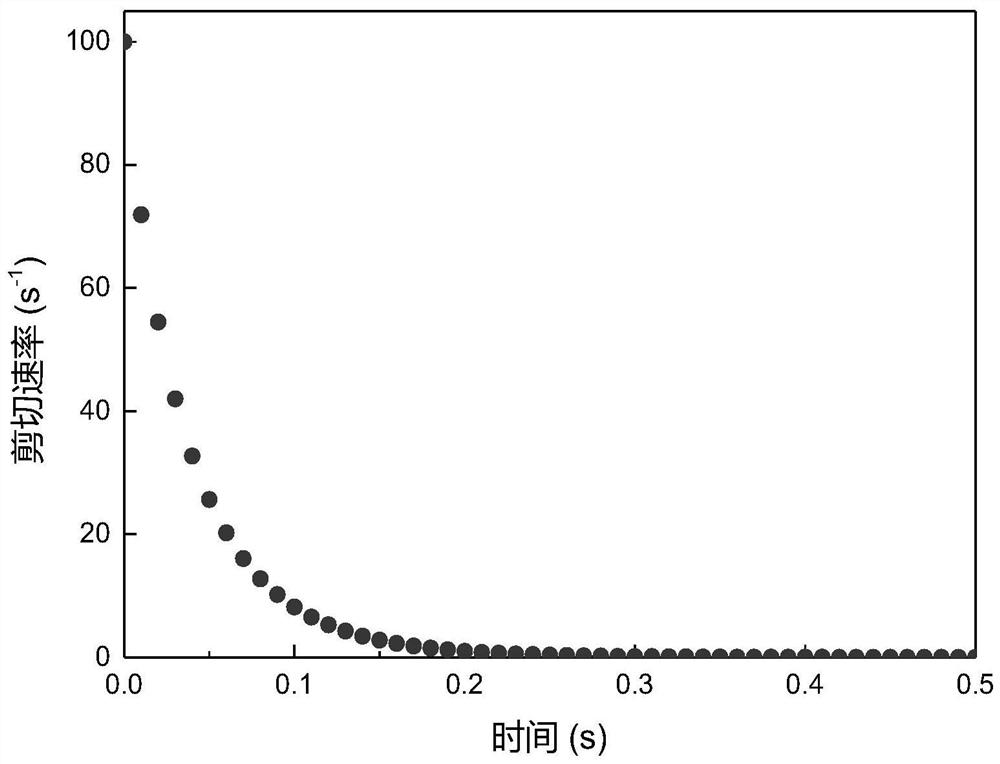

[0052] First, use Ultra high performance concrete premix (no sand) and Series of polycarboxylate superplasticizers, with and without additions In the case of the concrete thickener, two kinds of UHPC slurries were prepared; denoted as the first UHPC slurries and the second UHPC slurries, respectively.

[0053] Then, the internal structure recovery index and the structure recovery relaxation time of the first UHPC pure paste and the second UHPC pure paste are respectively determined by the evaluation method provided by the present invention.

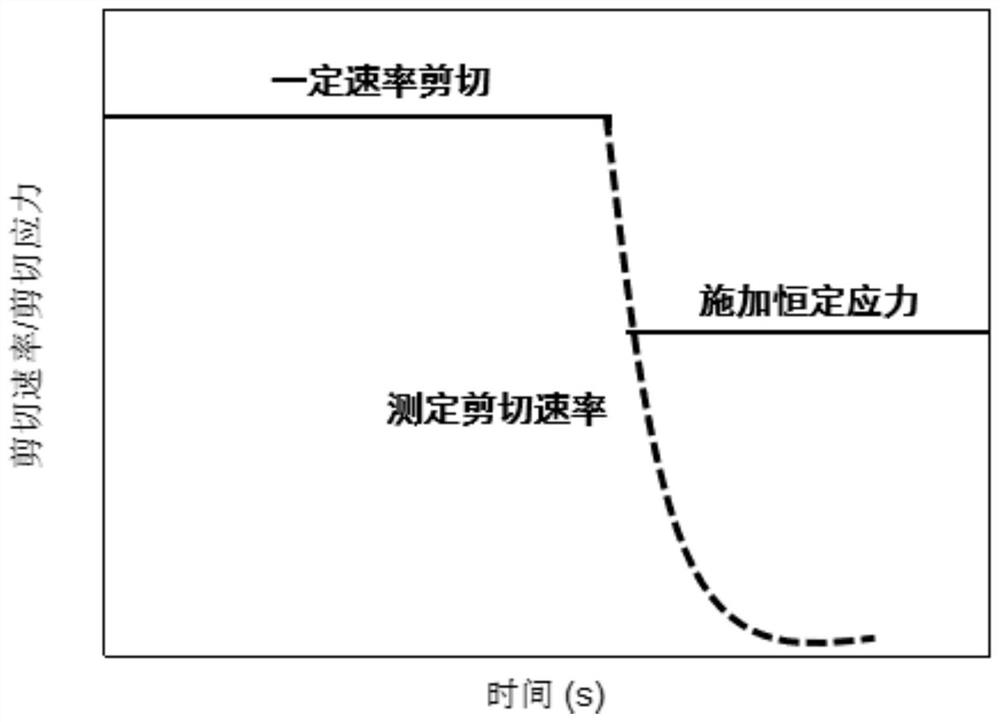

[0054] Specifically, the measurement methods of the internal structure recovery index and the structure recovery relaxation time of the first UHPC pure pulp and the second UHPC pure pulp are as follows: (1) The UHPC pure pulp is loaded into the flat plate rotary rheometer. In the silo, "100s -1 Pre-shear - 1Pa constant shear stress - 100s -1 Pre-shear - 3Pa constant shear stress - 100s -1 Pre-shear - 5Pa constant shear stress - 10...

Embodiment 2

[0059] First, use Ultra-high performance concrete premix (no sand), ordinary river sand with particle size not exceeding 1.18mm, and Series of polycarboxylate superplasticizers, with and without additions In the case of the concrete thickener, two UHPC mortars were prepared; denoted as the first UHPC mortar and the second UHPC mortar, respectively.

[0060] Then, the internal structure recovery index and the structure recovery relaxation time of the first UHPC mortar and the second UHPC mortar are respectively determined by the evaluation method provided by the present invention.

[0061] Specifically, the method for measuring the internal structure recovery index and the structure recovery relaxation time of the first UHPC mortar and the second UHPC mortar adopts the following methods: (1) Load the UHPC mortar into the material cup of the coaxial cylindrical rheometer , using "50s -1 Pre-cut, 0s -1 -50s -1 -0s -1 The rheological test was carried out using the linear ...

Embodiment 3

[0066] First, use Ultra-high performance concrete premix (no sand), ordinary river sand with particle size not exceeding 1.18mm, and Series of polycarboxylate superplasticizers, with and without additions In the case of the concrete thickener, two UHPC mortars were prepared; denoted as the third UHPC mortar and the fourth UHPC mortar, respectively.

[0067] Then, the internal structure recovery index and the structure recovery relaxation time of the third UHPC mortar and the fourth UHPC mortar are respectively determined by the evaluation method provided by the present invention.

[0068] Specifically, the method for measuring the internal structure recovery index and the structure recovery relaxation time of the third UHPC mortar and the fourth UHPC mortar adopts the following methods: (1) Load the UHPC mortar into the material cup of the coaxial cylindrical rheometer , using "30s -1 Pre-cut, 0s -1 -30s -1 -0s -1 The rheological test was carried out using the “linear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com