Method for treating niobium oxide gate tube by using supercritical fluid with hydrogen peroxide as reactant

A technology of supercritical fluid and niobium oxide, applied in the direction of electrical components, etc., can solve the problems of continuous reduction, functional layer thickness reduction, mobility and reliability reduction, etc., achieve performance optimization effect, increase gating ratio, and reduce OFF The effect of state current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

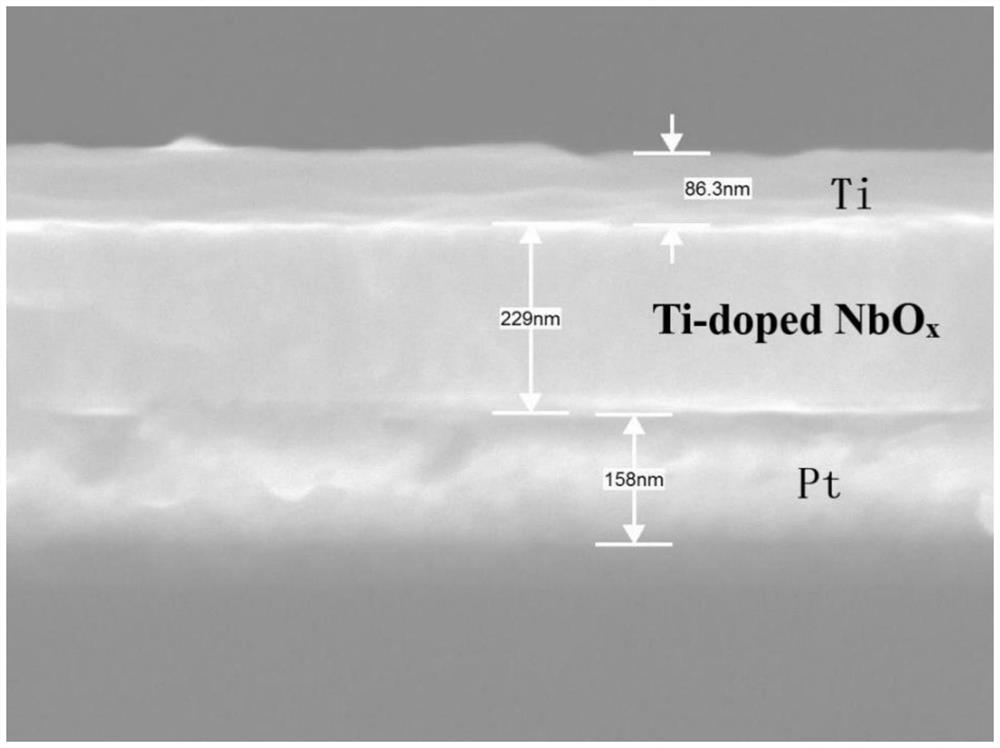

[0059] The preparation method of the niobium oxide gate tube of the present application can be prepared by a conventional magnetron sputtering method, and is specifically:

[0060] provide the bottom electrode;

[0061] Using metal titanium and niobium pentoxide as targets, and co-depositing on the surface of the bottom electrode by magnetron sputtering, titanium-doped niobium oxide is the conversion layer;

[0062] Using titanium metal as the target material, the titanium deposited on the surface of the conversion layer by magnetron sputtering is the top electrode;

[0063] In the process of preparing the conversion layer, the sputtering power of niobium pentoxide is 40-60W, and the sputtering power of titanium is 15-30W.

Embodiment 1

[0066] An embodiment of the present application provides a method for treating a niobium oxide gated tube with a supercritical fluid using hydrogen peroxide as a reactant, comprising the following steps:

[0067] S1. Provide a reaction chamber, use anhydrous ethanol to clean the reaction chamber, and then blow it dry; provide a quartz support, immerse the quartz support in 99.5% ethanol solution, ultrasonically vibrate, and after cleaning, blow the quartz support Dry; fix the niobium oxide gate tube on the quartz support, place the quartz support with the niobium oxide gate tube fixed in the reaction chamber, and add 500 μL of deionized water and 10 μL of 30% hydrogen peroxide into the reaction chamber ;

[0068] S2. Pour supercritical carbon dioxide fluid into the reaction chamber, control the pressure in the reaction chamber to be 3000 psi and the temperature to be 120°C, and react for 1.5 hours, and take out the niobium oxide gate tube after cooling down and releasing the p...

Embodiment 2

[0074] The method for treating a niobium oxide gated tube with a supercritical fluid using hydrogen peroxide as a reactant provided in the embodiment of the present application is the same as that in Example 1, except that 20 μL of hydrogen peroxide with a mass concentration of 30% is added in step S1, and the remaining process conditions are the same as Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com