A kind of preparation method of carbon quantum dot fluorescent material

A technology of carbon quantum dots and fluorescent materials, applied in the field of fluorescent material preparation, can solve the problems of increasing complexity and difficulty in obtaining long-term guarantee of fluorescent properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Clean and dry the substrate. First place the glass sheet in acetone for 5-10 minutes of ultrasonic cleaning, then use deionized water to ultrasonically wash the glass sheet for 4-6 minutes, then place it in absolute ethanol for 5-10 minutes, and then use deionized water Ultrasonic rinse the glass slide again for 4-6 minutes, and finally dry it with nitrogen;

[0018] (2) The reaction chamber is pre-evacuated. Use mechanical pumps, Roots pumps, molecular pumps and other vacuum equipment to pre-evacuate the reaction chamber at 100 °C until the pressure is lower than 10 -4 Pa;

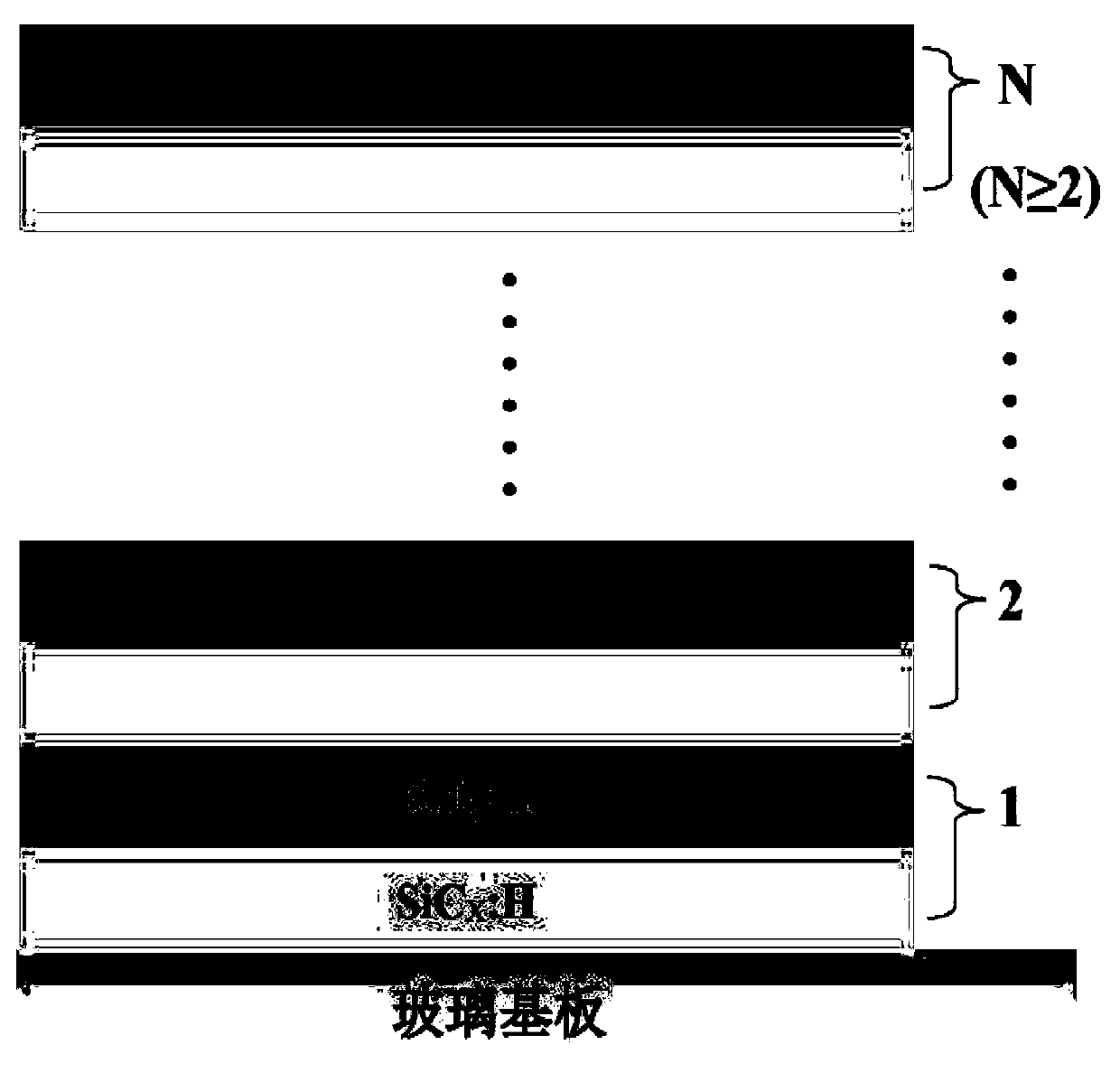

[0019] (3) Preparation of multilayer films embedded with carbon quantum dots. First, methane and silane were used as working gases, and SiC with carbon quantum dots embedded in the reaction chamber in step (2) was alternately prepared on the glass substrate by using plasma-enhanced chemical vapor deposition technology. X :H and CNx:H multilayer films. SiC X :H film specific preparation p...

Embodiment 2

[0023] (1) Clean and dry the substrate. First place the glass sheet in acetone for 5-10 minutes of ultrasonic cleaning, then use deionized water to ultrasonically wash the glass sheet for 4-6 minutes, then place it in absolute ethanol for 5-10 minutes, and then use deionized water Ultrasonic rinse the glass slide again for 4-6 minutes, and finally dry it with nitrogen;

[0024] (2) The reaction chamber is pre-evacuated. Use mechanical pumps, Roots pumps, molecular pumps and other vacuum equipment to pre-evacuate the reaction chamber at 100 °C until the pressure is lower than 10 -4 Pa;

[0025] (3) Preparation of multilayer films embedded with carbon quantum dots. First, methane and silane were used as working gases, and SiC with carbon quantum dots embedded in the reaction chamber in step (2) was alternately prepared on the glass substrate by using plasma-enhanced chemical vapor deposition technology. X :H and CNx:H multilayer films. SiC X :H film specific preparation p...

Embodiment 3

[0029] (1) Clean and dry the substrate. First place the glass sheet in acetone for 5-10 minutes of ultrasonic cleaning, then use deionized water to ultrasonically wash the glass sheet for 4-6 minutes, then place it in absolute ethanol for 5-10 minutes, and then use deionized water Ultrasonic rinse the glass slide again for 4-6 minutes, and finally dry it with nitrogen;

[0030] (2) The reaction chamber is pre-evacuated. Use mechanical pumps, Roots pumps, molecular pumps and other vacuum equipment to pre-evacuate the reaction chamber at 100 °C until the pressure is lower than 10 -4 Pa;

[0031] (3) Preparation of multilayer films embedded with carbon quantum dots. First, methane and silane were used as working gases, and SiC with carbon quantum dots embedded in the reaction chamber in step (2) was alternately prepared on the glass substrate by using plasma-enhanced chemical vapor deposition technology. X :H and CNx:H multilayer films. SiC X:H film specific preparation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com