Method for preparing molybdenum trioxide nanowire by sol-gel method

A molybdenum trioxide, sol-gel technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, etc., can solve the problems of irregular product structure distribution, high requirements on experimental equipment, limited industrial application, etc., and achieves low requirements on experimental equipment and is widely popularized Application value, high uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

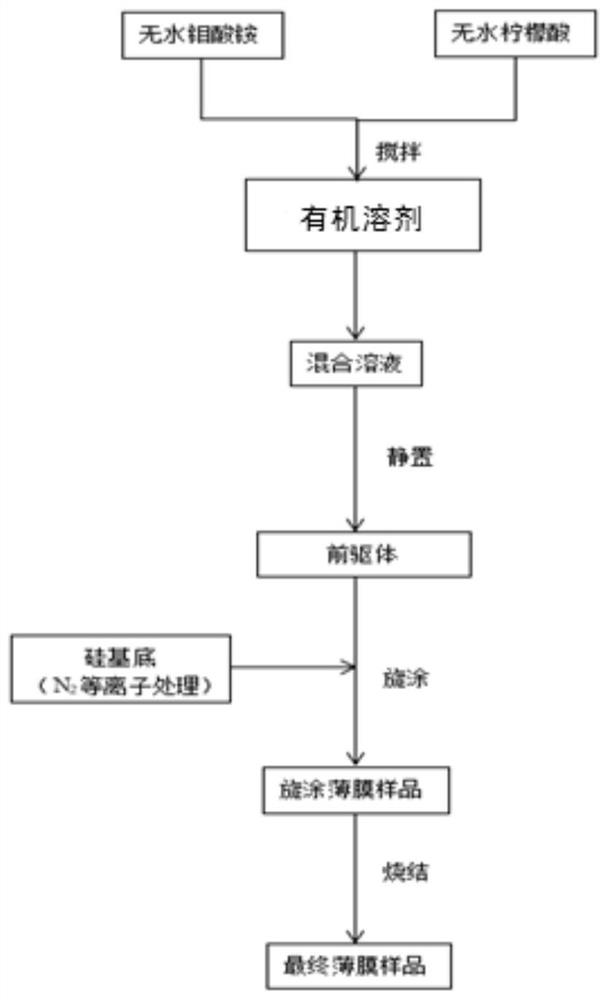

[0044]Mix 0.5 mol of anhydrous ammonium molybdate and 1.5 mol of anhydrous citric acid, stir magnetically for 4 hours at room temperature, dissolve in 5 mL of N,N-dimethylformamide (DMF) solvent, and let stand for 24 hours at room temperature Then, with the sufficient progress of the hydrolysis and polycondensation reactions, a uniform sol-gel precursor is formed.

[0045] The silica glass substrate with N 2 Plasma cleaning was performed for 1 min, and 300 μL of the precursor solution after aging (aging temperature was room temperature for 24 h) was taken to completely cover the silica glass substrate, and then spin-coating at 1000 rpm for 10 s. Finally, sintered in a 673K muffle furnace for 15 min to obtain a thin film sample.

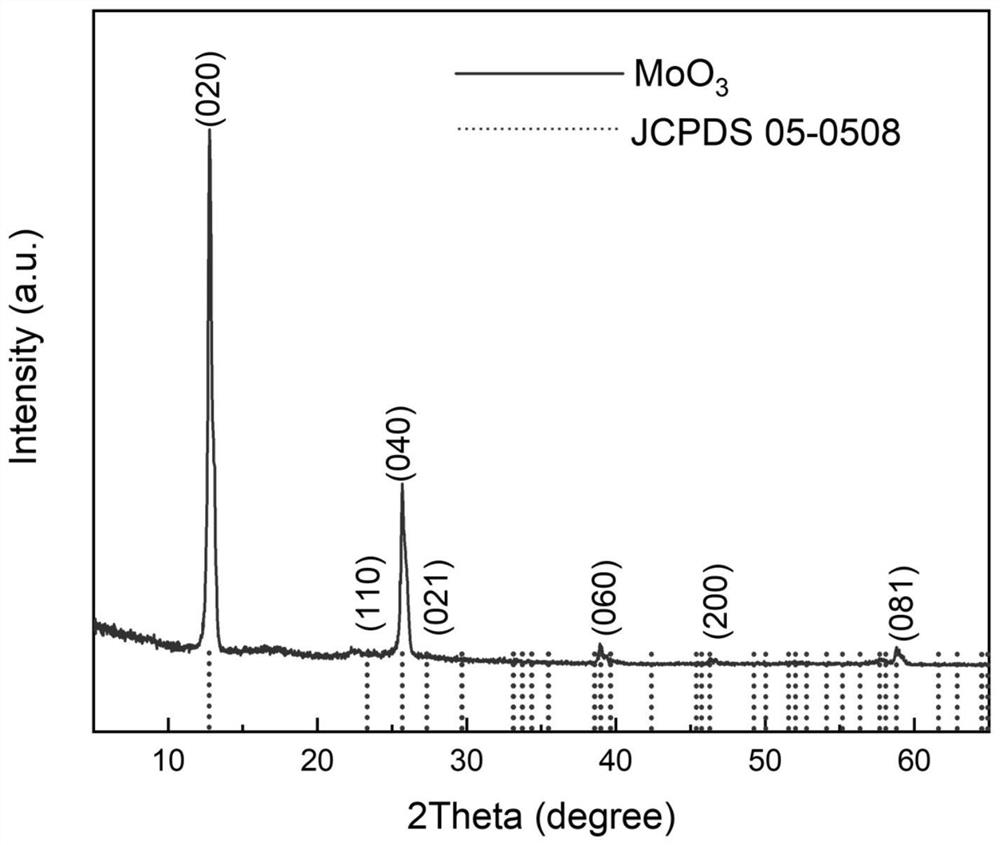

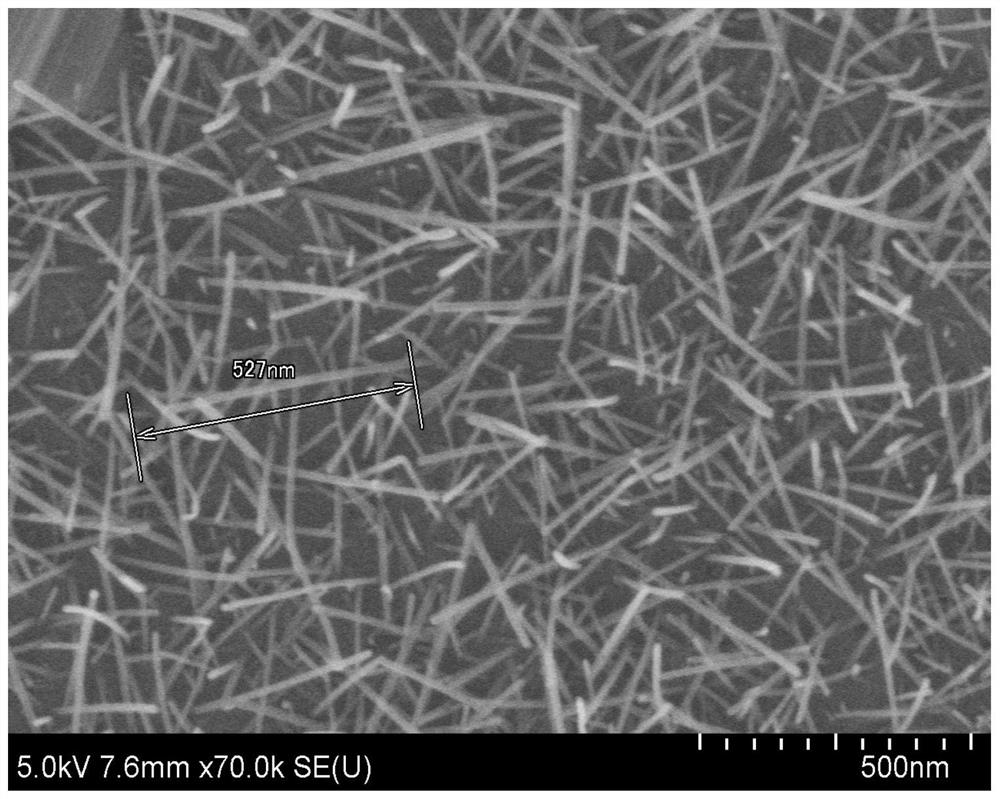

[0046] figure 2 It is the XRD picture of the molybdenum trioxide nanowire prepared in Example 1. It can be seen from the figure that all the characteristic diffraction peaks of the prepared sample and the pure-phase molybdenum trioxide JCPDS card...

Embodiment 2

[0052] Mix 0.5 mol of anhydrous ammonium molybdate and 2 mol of anhydrous citric acid, stir magnetically for 4 hours at room temperature, dissolve in 5 mL of ethylene glycol methyl ether (2-ME) solvent, stand at room temperature for 24 hours, With the full progress of the hydrolysis and polycondensation reactions, a uniform sol-gel precursor is formed.

[0053] The silica glass substrate with N 2 Plasma cleaning was performed for 1 min, and 300 μL of the precursor solution after aging (aging temperature was room temperature for 24 h) was taken to completely cover the silica glass substrate, and then spin-coating at 1000 rpm for 10 s. Finally, sintered in a 673K muffle furnace for 15 min to obtain a thin film sample.

Embodiment 3

[0055] Mix 0.5 mol of anhydrous ammonium molybdate and 2.5 mol of anhydrous citric acid, stir magnetically for 4 hours at room temperature, dissolve in 5 mL of N,N-dimethylacetamide (DMAC) solvent, and let stand for 24 hours at room temperature Then, with the sufficient progress of the hydrolysis and polycondensation reactions, a uniform sol-gel precursor is formed.

[0056] The silica glass substrate with N 2 After plasma cleaning for 1 min, take 300 μL of the precursor solution after aging (the aging temperature is room temperature, and the time is 24 h) to completely cover the silica glass substrate, and then spin-coating at 1000 rpm for 10 s. Finally, sintered in a 673K muffle furnace for 15 min to obtain a thin film sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com