Damping self-resetting tunnel structure for fault fracture zone

A technology of tunnel structure and broken zone, which is applied to tunnels, tunnel linings, shaft equipment, etc., can solve the problems of limited ability to resist fault dislocation, reduce stiffness, and reduce the length of lining segments, etc., so as to reduce the time for emergency repairs, The effect of reducing the degree of misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

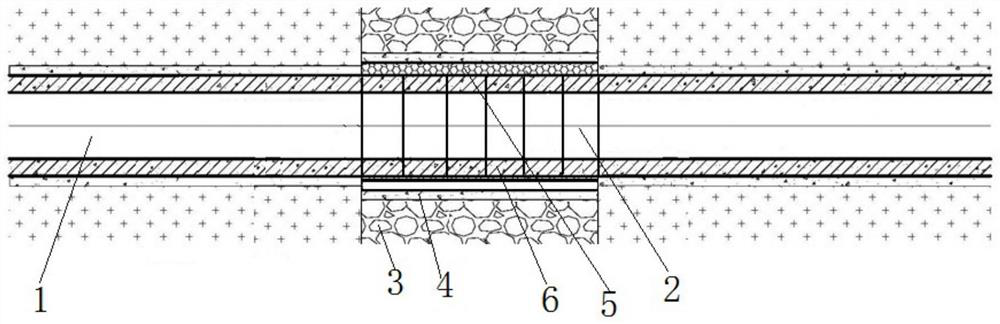

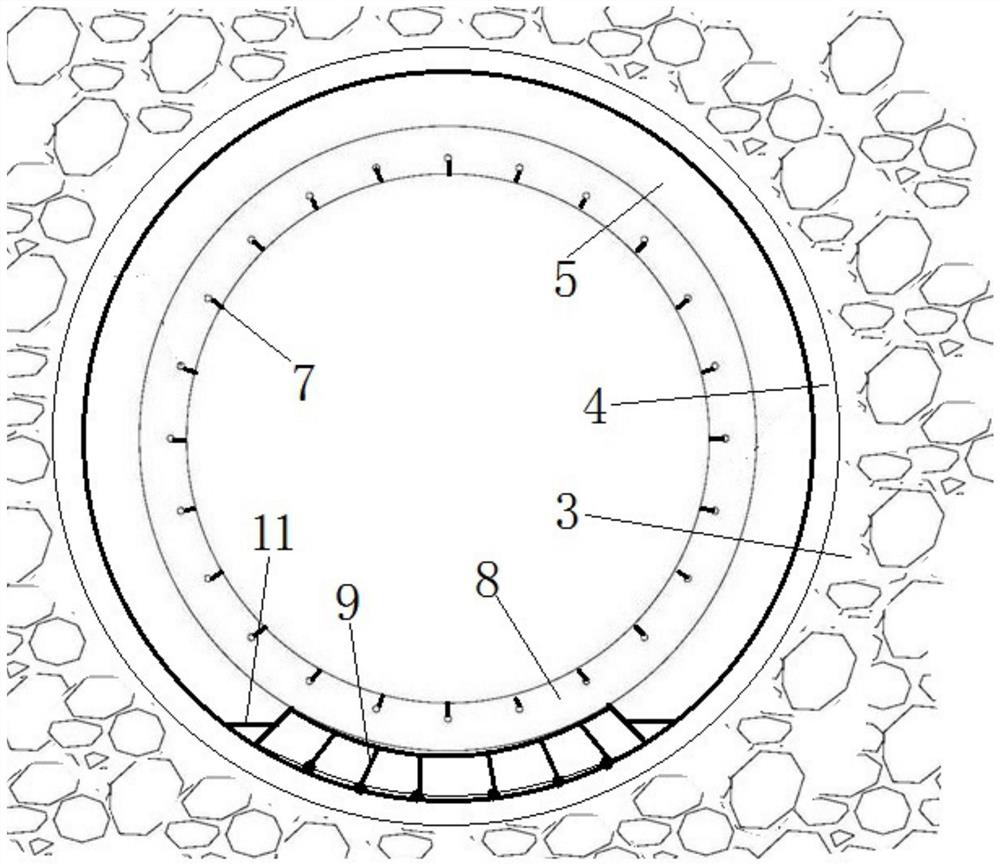

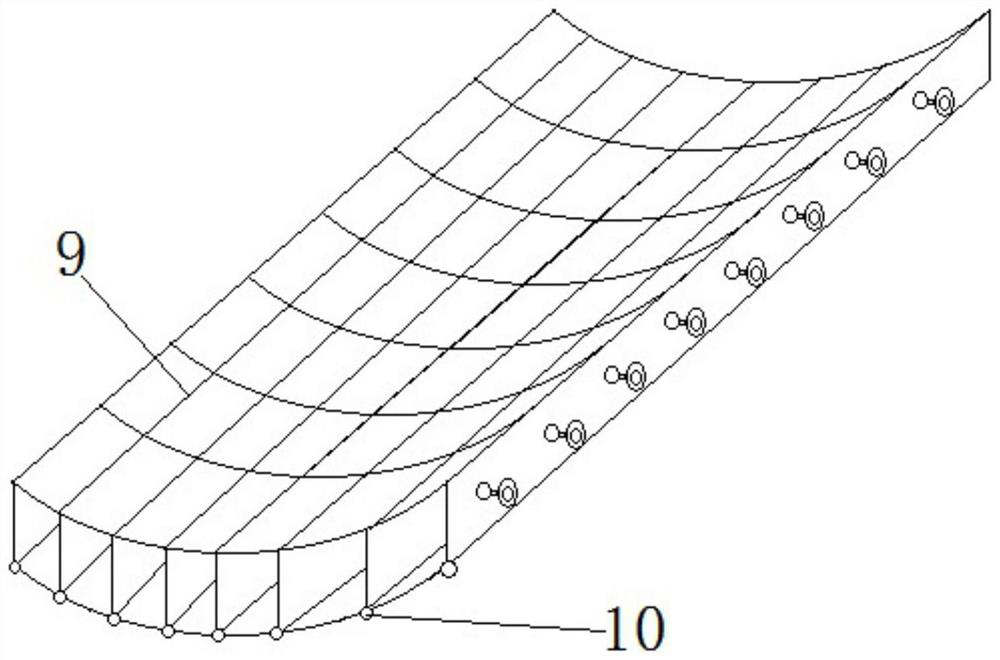

[0034] The present invention provides a shock-absorbing self-resetting tunnel structure for fault fracture zone, the overall structure of which is as follows: figure 1 As shown in the figure, the two sides of the fault fracture zone are normal mountains, and the ordinary tunnel structure can be used here for construction, that is, figure 1 The common section 1 shown in ; the excavation is to be carried out in the area of the fault broken zone, that is, the excavation section 2, and the cross-sectional structure of the excavation section is as follows figure 2 As shown: the excavation section sequentially includes a primary lining layer 4 in contact with the surrounding rock 3, an elastic shock absorbing layer 5 filled with elastic shock absorbing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com