Multi-channel discharge large-area distributed ignition system and method

An ignition system, distributed technology, applied in the direction of engine ignition, combustion engine, machine/engine, etc., can solve the problems of loss of multi-point ignition, single, small discharge channel coverage, etc., to improve the ignition success rate and accelerate the combustion speed , the effect of improving ignition stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 of the present disclosure introduces a large-area distributed ignition system with multi-channel discharge.

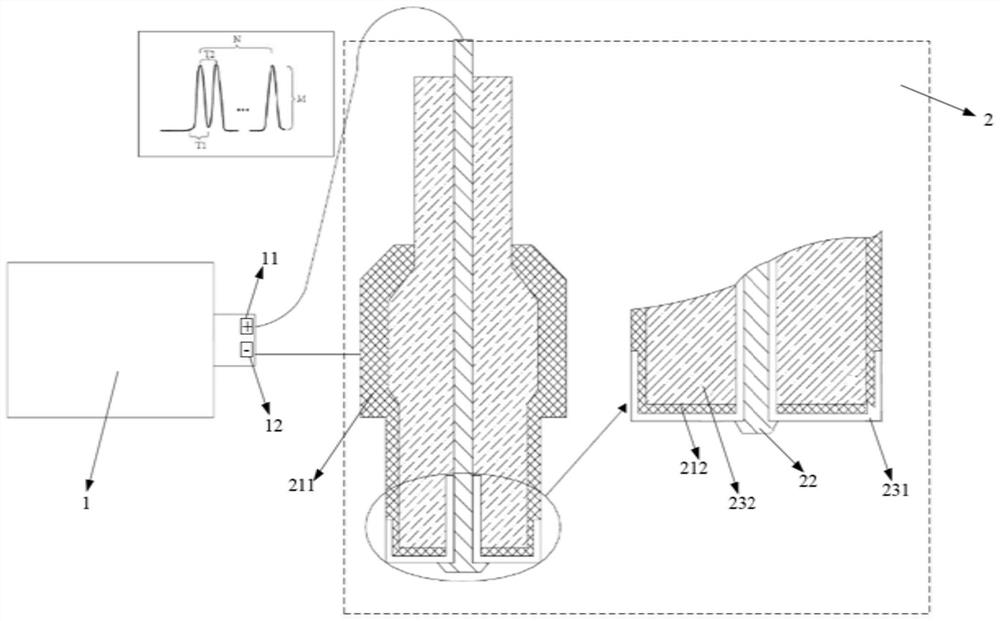

[0044] like figure 1 and figure 2 The shown multi-channel discharge large-area distributed ignition system includes a pulse generator 1 and a multi-channel discharge distributed ignition electrode 2 .

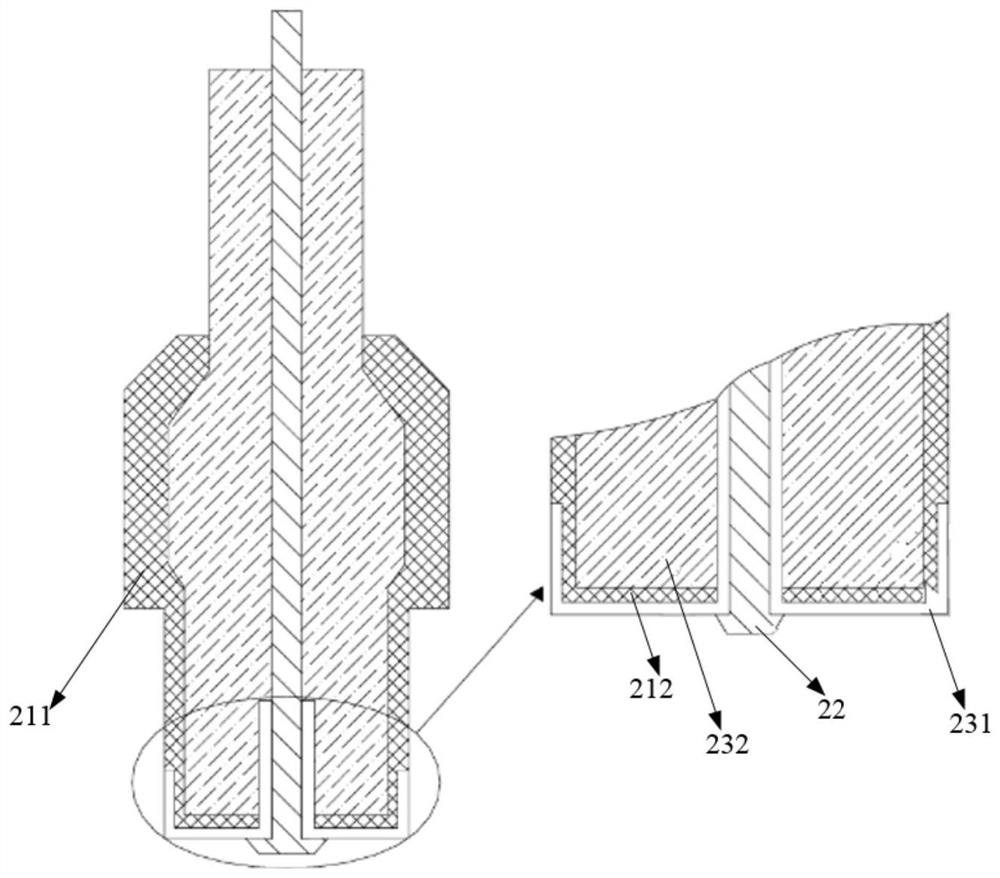

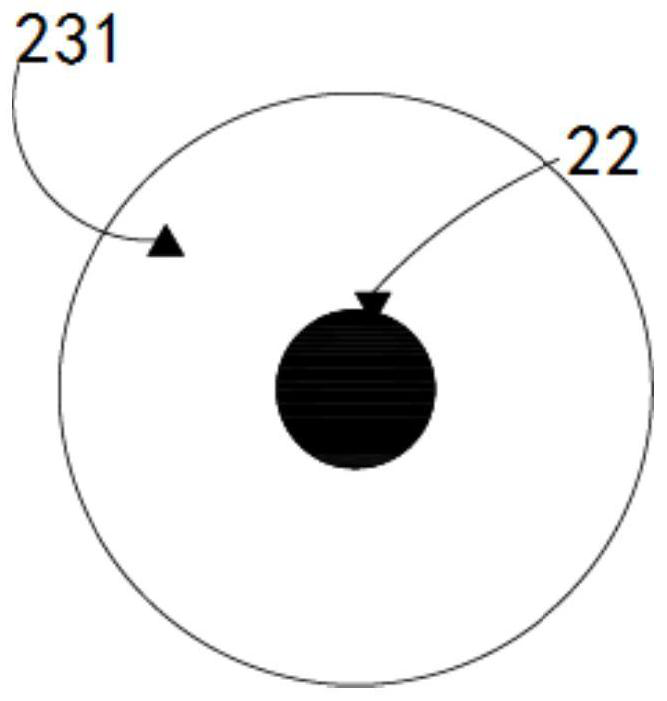

[0045] In this embodiment, the multi-channel discharge distributed ignition electrode 2 has a columnar structure, and includes an inner electrode 21 , an outer electrode 22 and an insulating medium 23 .

[0046] The outer electrode 22 is arranged at the central axis of the multi-channel discharge distributed ignition electrode 2. One end of the outer electrode 22 extends out of one side of the multi-channel discharge distributed ignition electrode 2 and is connected to the positive electrode 11 of the pulse generator 1. The outer electrode 22 The other end of the truncated truncated structure extends out of the other side of the multi-channel disc...

Embodiment 2

[0055] The second embodiment of the present disclosure provides a multi-channel discharge large-area distributed ignition method, which adopts the multi-channel discharge large-area distributed ignition system provided in the first embodiment.

[0056] A large-area distributed ignition method for multi-channel discharge, comprising the following steps:

[0057] Apply high frequency, high voltage and fast pulse parameters to the pulse generator;

[0058] Under the action of the applied high-frequency high-voltage fast pulse, the edge of the outer electrode in the shape of a truncated cone generates a plurality of filamentary discharge channels along the surface of the insulating thin layer to realize multi-point ignition.

[0059] Adjust the pulse amplitude, pulse number and power repetition frequency of the pulse generator to realize the adjustment of high frequency, high voltage and fast pulse parameters.

[0060] As one or more embodiments, the pulse amplitude and the numbe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap