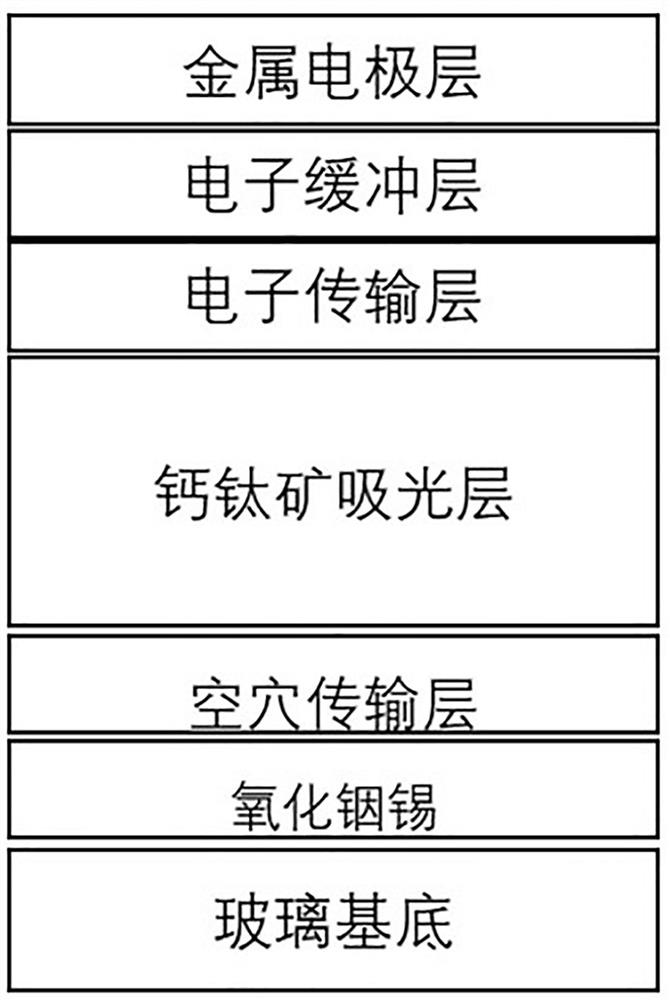

Wide-band-gap perovskite thin film, solar cell and preparation method of wide-band-gap perovskite thin film

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of solar cell stability and low efficiency, and achieve beneficial effects of excellent efficiency and stability, excellent photoelectric conversion characteristics, and light work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

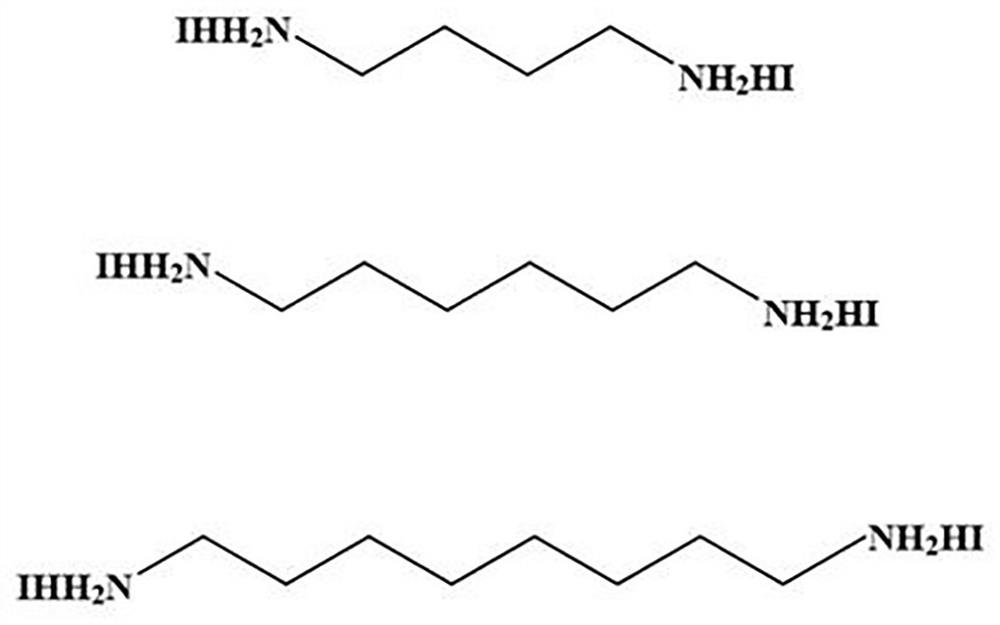

[0056] The present embodiment provides a method for preparing a solar cell, comprising the following steps:

[0057] (1) Cleaning the ITO substrate: ultrasonically cleaned with detergent, deionized water, ethanol and isopropanol for 15 min each. Washed substrate with N 2 Dry with an air gun, put it in a watch glass, and treat it with UV-ozone cleaning equipment for 20 min before use.

[0058] (2) Preparation of hole transport layer: The ozone-treated ITO substrate was placed on the rotating bracket of the spin coater and fixed by vacuum adsorption. The hole transport material PTAA (poly[bis(4-phenyl)(2, 4,6-trimethylphenyl)amine]) and chlorobenzene solution were mixed at a mass-volume ratio of 2 mg: 1 mL to obtain a PTAA solution. The PTAA solution was dropped in the center of the ITO substrate and the spin coater was started at 3000 rpm for 30 s. Spin-coated on the ITO substrate, each 30 μL of PTAA solution corresponds to an area of 1 × 1 cm of the ITO substrate 2 ; Then...

Embodiment 2

[0064] The present embodiment provides a method for preparing a solar cell, comprising the following steps:

[0065] (1) Cleaning the ITO substrate: ultrasonically cleaned with detergent, deionized water, ethanol and isopropanol for 15 min each. Washed substrate with N 2 Blow dry with an air gun, put it in a watch glass, and treat it with UV-ozone cleaning equipment for 20 min before use.

[0066] (2) Preparation of hole transport layer: The ozone-treated ITO substrate was placed on the rotating bracket of the spin coater and fixed by vacuum adsorption. The hole transport material PTAA and chlorobenzene solution were mixed in a mass-volume ratio of 2 mg: 1 mL. To obtain PTAA solution, drop the PTAA solution on the center of the ITO substrate and start the spin coater to spin on the ITO substrate at a speed of 3000rpm for 30s. Each 30μL of PTAA solution corresponds to an area of 1×1 cm of the ITO substrate. 2 ; Then the sample was moved to a heating stage at 100 °C and anne...

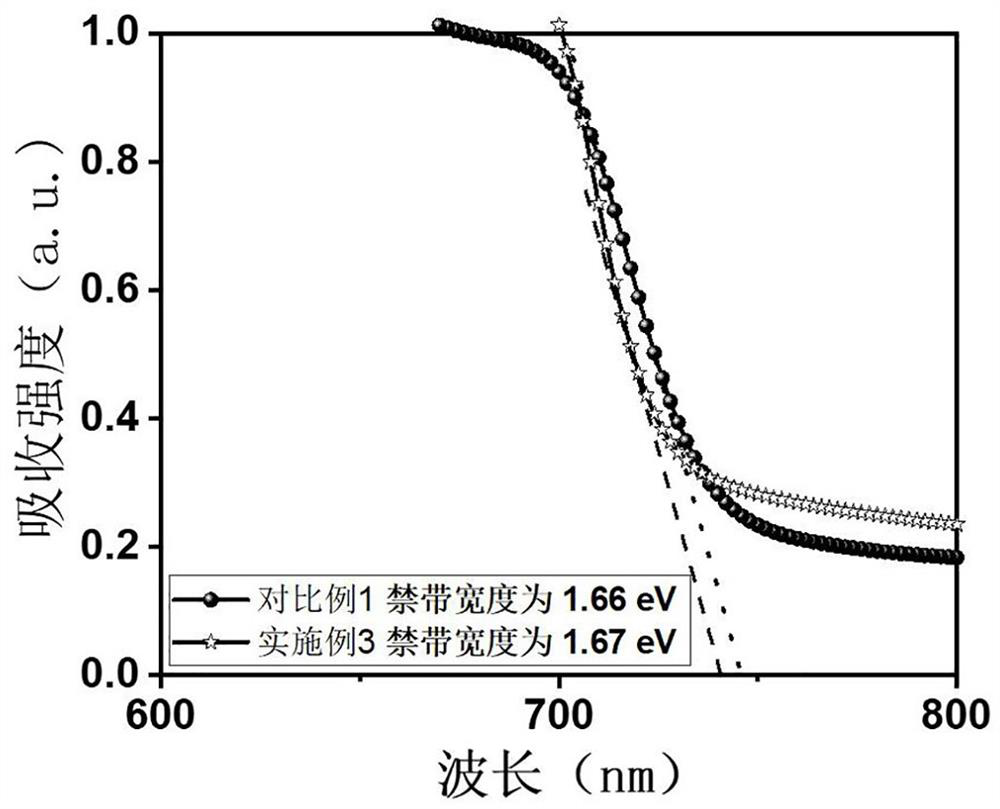

Embodiment 3

[0072] The present embodiment provides a method for preparing a solar cell, comprising the following steps:

[0073] (1) Cleaning the ITO substrate: ultrasonically cleaned with detergent, deionized water, ethanol and isopropanol for 15 min each. Washed substrate with N 2 Blow dry with an air gun, put it in a watch glass, and treat it with UV-ozone cleaning equipment for 20 min before use.

[0074] (2) Preparation of hole transport layer: The ozone-treated ITO substrate was placed on the rotating bracket of the spin coater and fixed by vacuum adsorption. The hole transport material PTAA and chlorobenzene solution were mixed in a mass-volume ratio of 2 mg: 1 mL. To obtain the PTAA solution, drop the PTAA solution on the center of the ITO substrate and start the spin coater to spin on the ITO substrate at a speed of 3000 rpm for 30 s. Each 30 μL of PTAA solution corresponds to an area of 1 × 1 cm of the ITO substrate. 2 ; Then the sample was moved to a heating stage at 100 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com