Short-process severe plastic deformation preparation method of large-specification rare earth magnesium alloy high-performance ingot blank

A technology of plastic deformation and rare earth magnesium, which is applied in the field of metal plastic processing, can solve the problems of uneven metal flow, discounted strengthening effect, fast intermediate flow, etc., and achieve the effect of reducing chip processing procedures, reducing the number of times of upsetting and extrusion, and simple reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

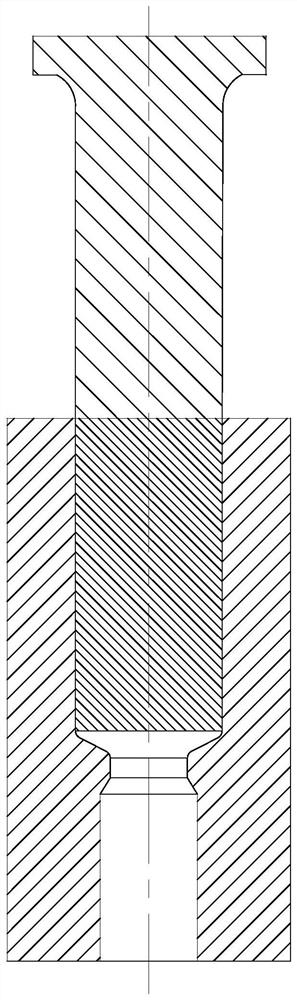

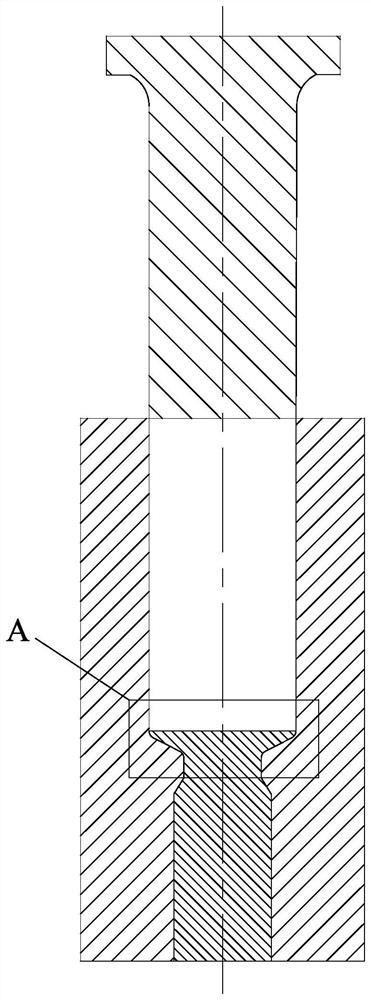

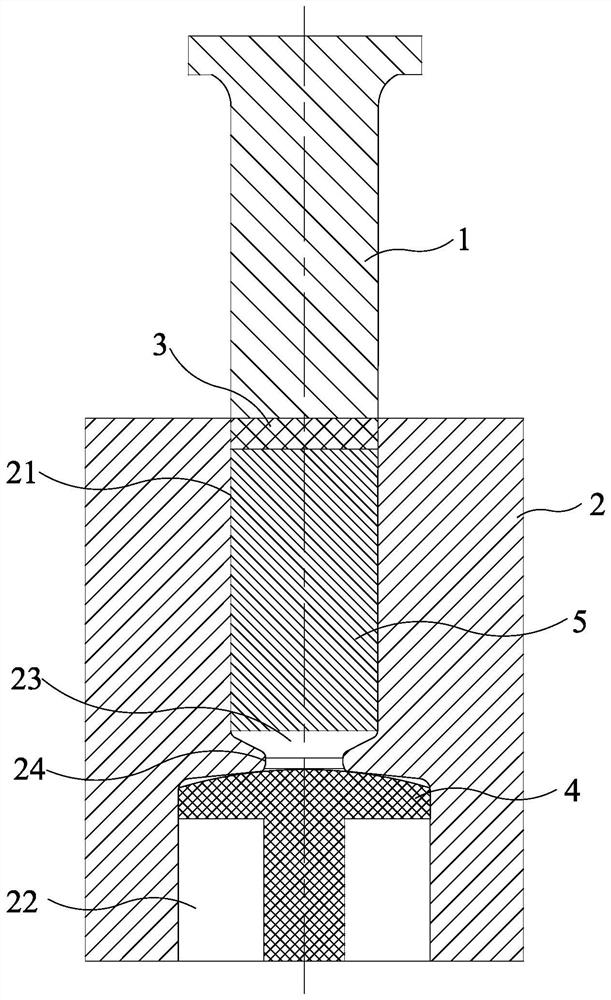

[0031] In order to illustrate the embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the accompanying drawings that are used in the description of the embodiments or the prior art. Obviously, the drawings in the following description are only These are some embodiments of the present invention, and for those of ordinary skill in the art, other drawings can also be obtained from these drawings without any creative effort.

[0032] The invention relates to a mold for preparing large-scale rare earth magnesium alloy high-performance ingots by short-flow drastic plastic deformation, such as image 3 As shown, it includes a punch 1 installed on the upper table of the press (not shown in the figure), a female die 2 installed on the lower table of the press (not shown in the figure), a recoverable excess pressure block 3, and a connecting pressure The back pressure plate 4 and the extrusion recovery die 6 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com