Preparation method of optical modulator based on glass microstructure array

A glass microstructure and optical modulator technology, applied in glass manufacturing equipment, glass molding, microstructure technology, etc., can solve the problems of long processing time, difficult molding, high cost, etc., to improve light transmission performance and reduce glass- Silicon bonding step, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

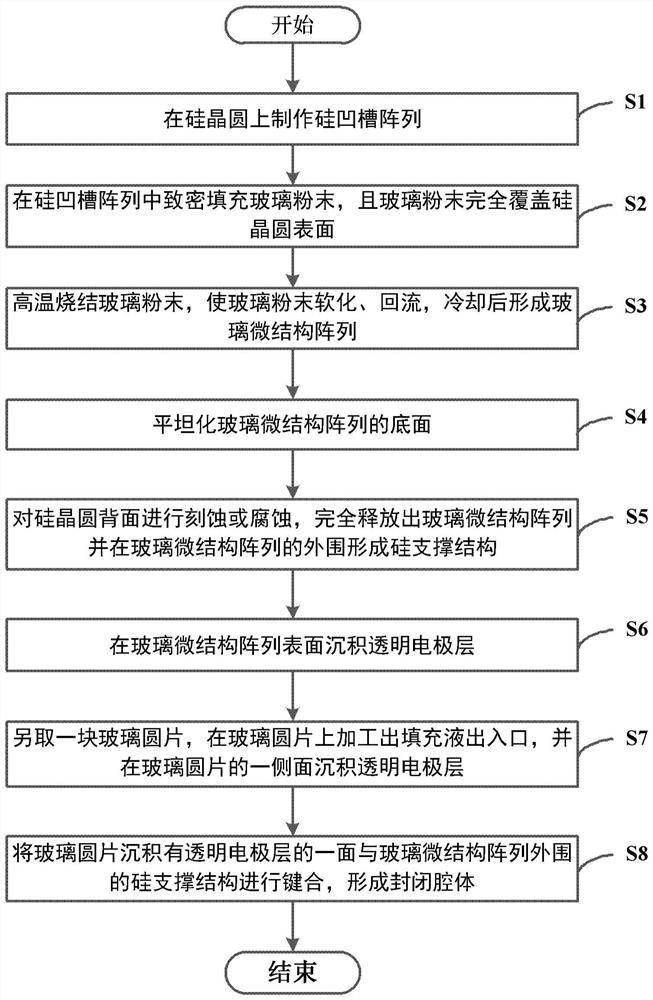

[0046] The preparation method of an optical modulator based on a glass microstructure array provided by the present disclosure utilizes nano-glass powder sintering and thermal reflow molding to realize the preparation of ultra-high depth and width glass microstructures, such as figure 1 As shown, the method includes the following steps:

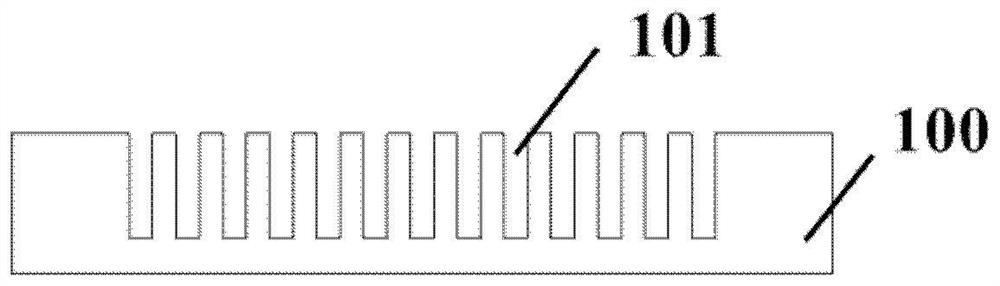

[0047] Step S1: fabricating a silicon groove array on a silicon wafer;

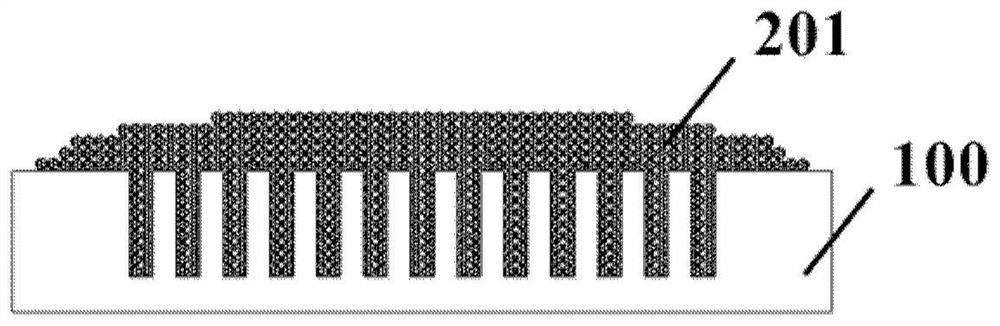

[0048] Step S2: densely filling the silicon groove array with glass powder, and the glass powder completely covers the surface of the silicon wafer;

[0049] Step S3: sintering the glass powder at a high temperature to soften and reflow the glass powder, and form a glass microstructure array after cooling;

[0050] Step S4: planarizing the bottom surface of the glass microstructure array;

[0051] Step S5: etching or etching the back of the silicon wafer, completely releasing the glass microstructure array, and forming a silicon support structure on the periphery of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com