Preparation method of waterproof coating

A waterproof coating and equipment technology, applied in coating, climate sustainability, sustainable waste treatment, etc., can solve the problems of long production cycle and complex and cumbersome preparation process, and achieve shortened production cycle, low production cost and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

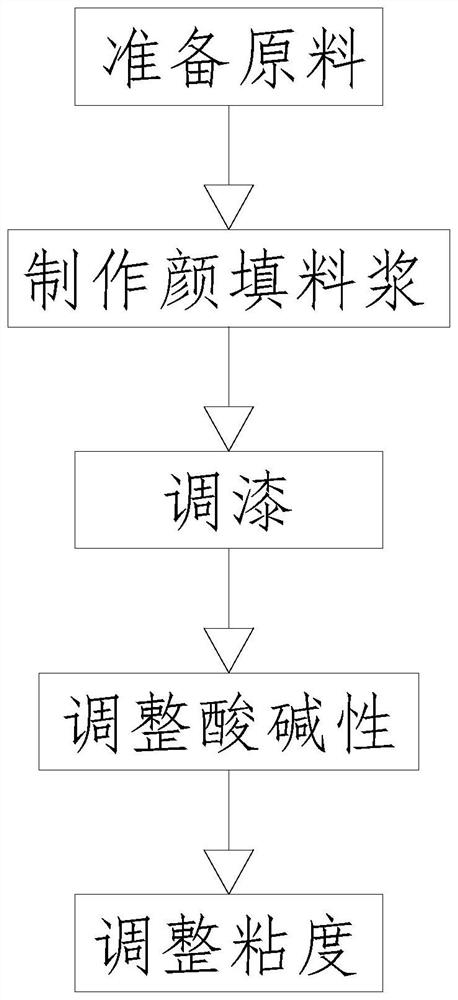

[0021] The invention provides a technical scheme: a preparation method of a waterproof coating, the preparation method steps are as follows:

[0022] The first step is to prepare raw materials, calculate each raw material according to the proportion, and prepare raw materials equal to the weight of the calculation result according to the calculation result;

[0023] The second step is to make pigment and filler slurry, add an appropriate amount of water to the grinding and dispersing equipment, then adjust the speed of the grinding and dispersing equipment to a low speed, add the corresponding additives to the grinding and dispersing equipment, then put in the pigment and filler powder, and then wash the machine ;

[0024] The third step is to adjust the paint, set the rotation speed of the grinding and dispersing equipment to 600 rpm, and then add the emulsion and the corresponding test auxiliaries to the grinding and dispersing equipment;

[0025] The fourth step is to adju...

Embodiment 2

[0036] The invention provides a technical scheme: a preparation method of a waterproof coating, the preparation method steps are as follows:

[0037] The first step is to prepare raw materials, calculate each raw material according to the proportion, and prepare raw materials equal to the weight of the calculation result according to the calculation result;

[0038] The second step is to make pigment and filler slurry, add an appropriate amount of water to the grinding and dispersing equipment, then adjust the speed of the grinding and dispersing equipment to a low speed, add the corresponding additives to the grinding and dispersing equipment, then put in the pigment and filler powder, and then wash the machine ;

[0039] The third step is to adjust the paint, set the rotation speed of the grinding and dispersing equipment to 700 rpm, and then add the emulsion and the corresponding test auxiliaries to the grinding and dispersing equipment;

[0040] The fourth step is to adju...

Embodiment 3

[0051] The invention provides a technical scheme: a preparation method of a waterproof coating, the preparation method steps are as follows:

[0052] The first step is to prepare raw materials, calculate each raw material according to the proportion, and prepare raw materials equal to the weight of the calculation result according to the calculation result;

[0053] The second step is to make pigment and filler slurry, add an appropriate amount of water to the grinding and dispersing equipment, then adjust the speed of the grinding and dispersing equipment to a low speed, add the corresponding additives to the grinding and dispersing equipment, then put in the pigment and filler powder, and then wash the machine ;

[0054] The third step is to adjust the paint, set the rotation speed of the grinding and dispersing equipment to 600 rpm, and then add the emulsion and the corresponding test auxiliaries to the grinding and dispersing equipment;

[0055] The fourth step is to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com