Method for depositing nanogold on surface of titanium dioxide nanotube array

A nanotube array and titanium dioxide technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., to achieve the effect of avoiding waste and improving deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0057] The only difference between the second embodiment and the embodiment is that the electrodeposition time in step S4 is 5 min, which is the same as that of the second embodiment.

Embodiment 3

[0059] The only difference between the second embodiment and the embodiment is that the electrodeposition time in step S4 is 30 min, which is the same as that.

Embodiment 4

[0061] The only difference between the second embodiment and the embodiment is that the electrodeposition time in step S4 is 60 min, which is the same as that.

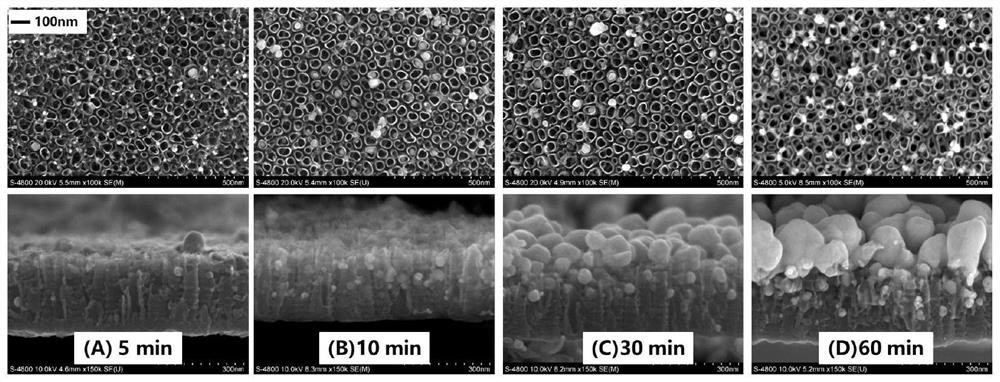

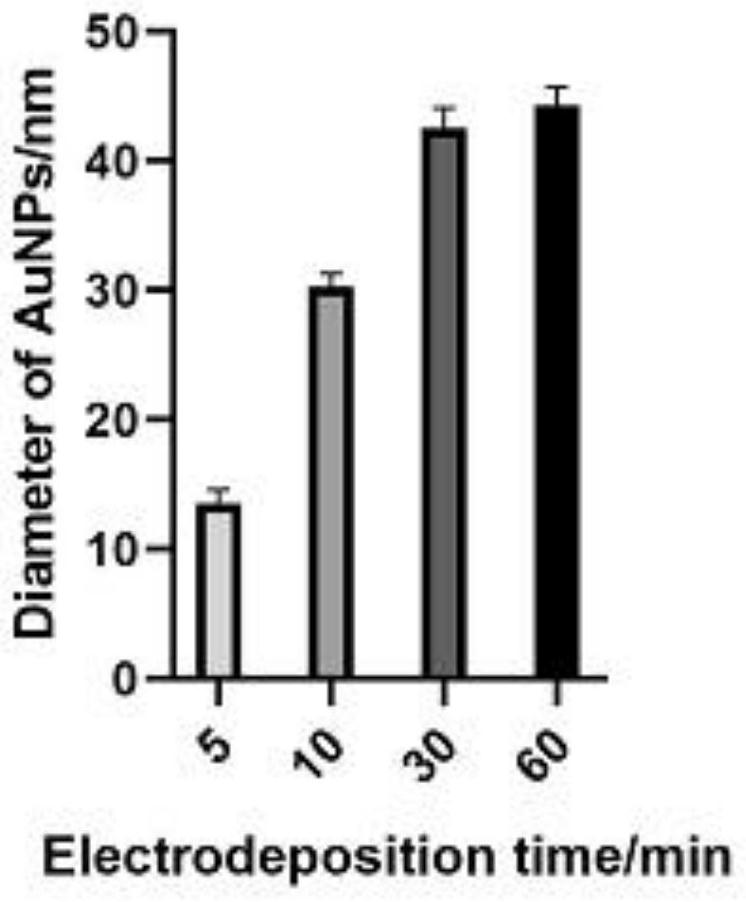

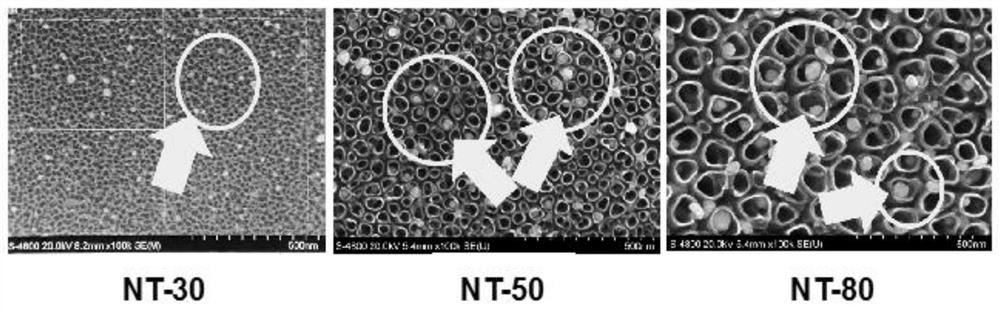

[0062] The morphology of gold nanoparticles deposited in Example 1 to Example 4 was compared and observed, and the results were as follows. figure 1 and attached figure 2 shown, from the attached figure 1 and 2 It can be seen that both the size and density of gold nanoparticles increased with the prolongation of deposition time. However, when the deposition time was 5min, the number of gold nanoparticles deposited was small, and the particle size was small, and the cavity of the nanotube was not completely filled; when the deposition time was 30min and 60min, the gold nanoparticles exceeded the mouth of the nanotube, resulting in poor particle size. Due to the limitation, large gold particles are produced, and the biological activity of large gold nanoparticles decreases, which is not conducive to biological exper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com