Water source heat pump hot water system for three-layer gradient utilization of waste water waste heat

A water source heat pump and hot water system technology, applied in residential hot water supply systems, heating systems, heat recovery systems, etc., can solve the problem of very large temperature difference between evaporation temperature and condensation temperature, low wastewater inlet temperature, and clean water outlet temperature Advanced problems, to achieve the effect of convenient transportation, small footprint and stable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will now be further described with reference to specific embodiments and accompanying drawings.

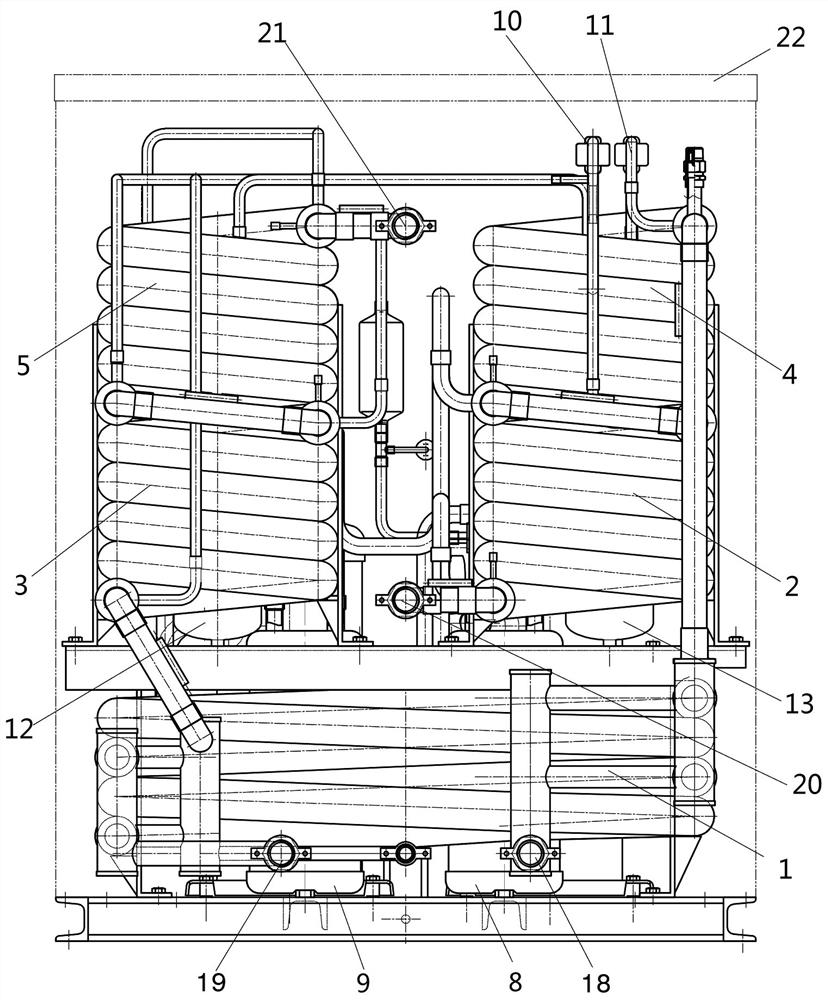

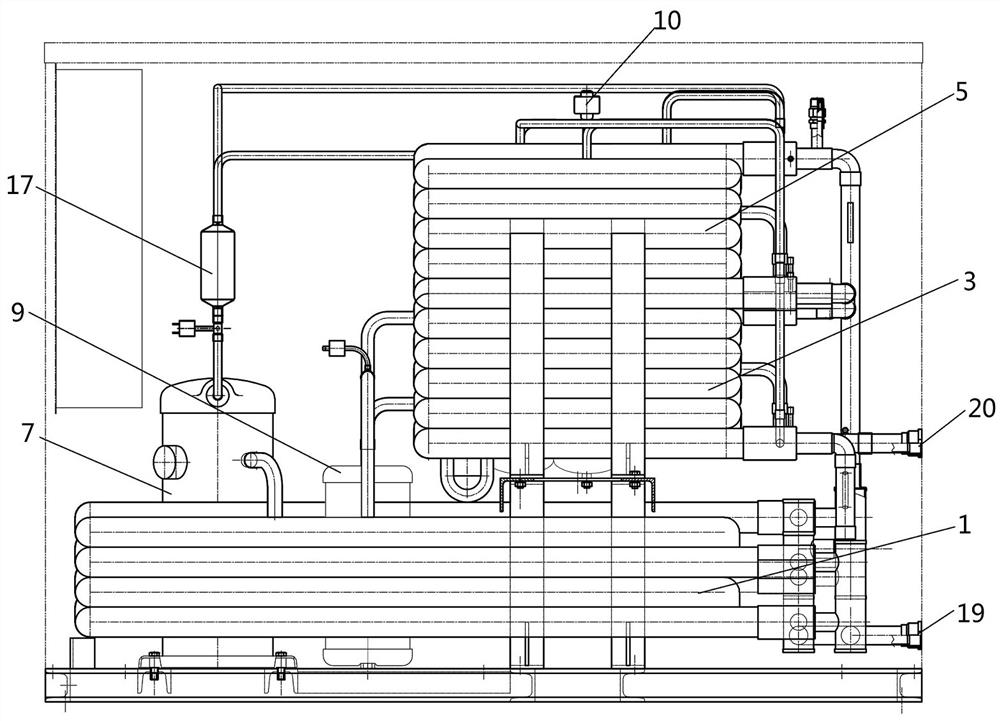

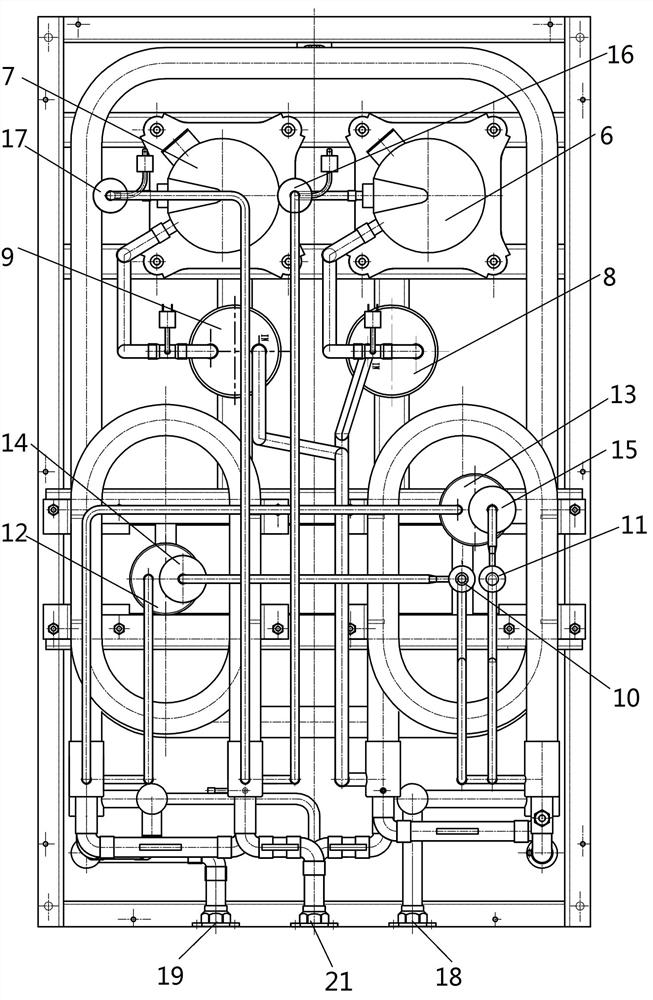

[0019] like figure 1 As shown in the figure, the present invention discloses a water source heat pump hot water system using three-layer cascade utilization of waste water waste heat, which is provided with a water-water heat exchanger 1, an evaporator I2, a condenser I3, an evaporator II4 and a condenser in order from bottom to top II5, the evaporator I2 and the evaporator II4 are connected in series to form an evaporator group, which is located on one side of the hot water system, and the condenser I3 and the condenser II5 are connected in series to form a condenser group, located on the other side of the hot water system. There are also compressor I6, compressor II7, gas-liquid separator I8, gas-liquid separator II9, throttle valve I10, throttle valve II11, liquid storage tank I12, liquid storage tank II13, from figure 1 From the front view, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com