Electrolyte solution for electrolytic capacitor, and electrolytic capacitor

An electrolytic capacitor and electrolyte technology, applied in the direction of electrolytic capacitors, liquid electrolytic capacitors, solid electrolytic capacitors, etc., can solve the problems of shell container expansion, pressure rise, increase in height and size of electrolytic capacitors, etc., to suppress expansion and suppress pressure. rising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The capacitor element obtained above is immersed in the above-mentioned conductive polymer dispersion liquid, the capacitor element is lifted up, and then the solvent is evaporated to form a solid electrolyte layer containing a conductive polymer.

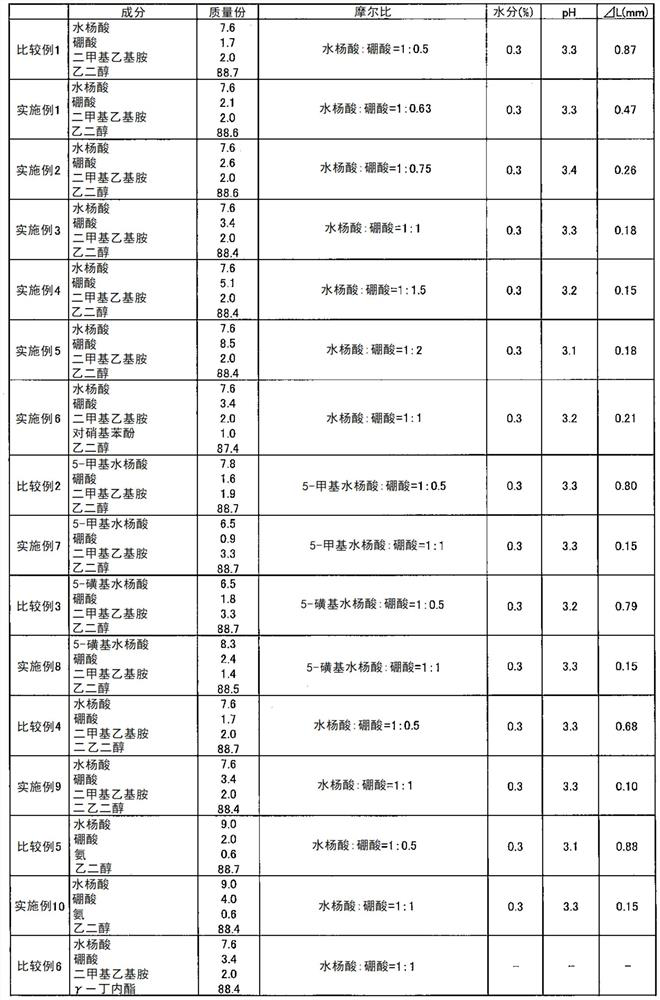

[0101] Next, each component of salicylic acid, boric acid, dimethylethylamine, and ethylene glycol in the amounts described in Table 1 was mixed while stirring at 90 to 95° C. to prepare an electrolytic solution, and the electrolytic solution was impregnated into the capacitor element. Next, the capacitor element was inserted into a bottomed cylindrical metal aluminum case (thickness of case material: 0.3 mm), a sealing rubber was attached to the opening end, and the sealing was performed by crimping. Then, aging treatment was performed on the condition of 105 degreeC, and the aluminum electrolytic capacitor was produced.

[0102] The rated voltage of the electrolytic capacitor was 35V, and the external dimensions of the se...

Embodiment 2~10、 comparative example 1~5

[0104]Examples 2 to 10 and Comparative Examples were prepared in the same manner as in Example 1, except that the electrolyte solution obtained by mixing the components in the amounts shown in Table 1 while stirring at 90 to 95° C. was used. 1 to 5 electrolytic capacitors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com