Treatment method of waste incineration fly ash

A technology for waste incineration fly ash and a treatment method, applied in the field of fly ash treatment, can solve the problem that the weather resistance, corrosion resistance and anti-aging ability of ton bag materials are limited, the shape and size of the solidified body are difficult to be completely consistent, and the landfill It can save the time of hanging bags, light weight, and compress the stacking spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

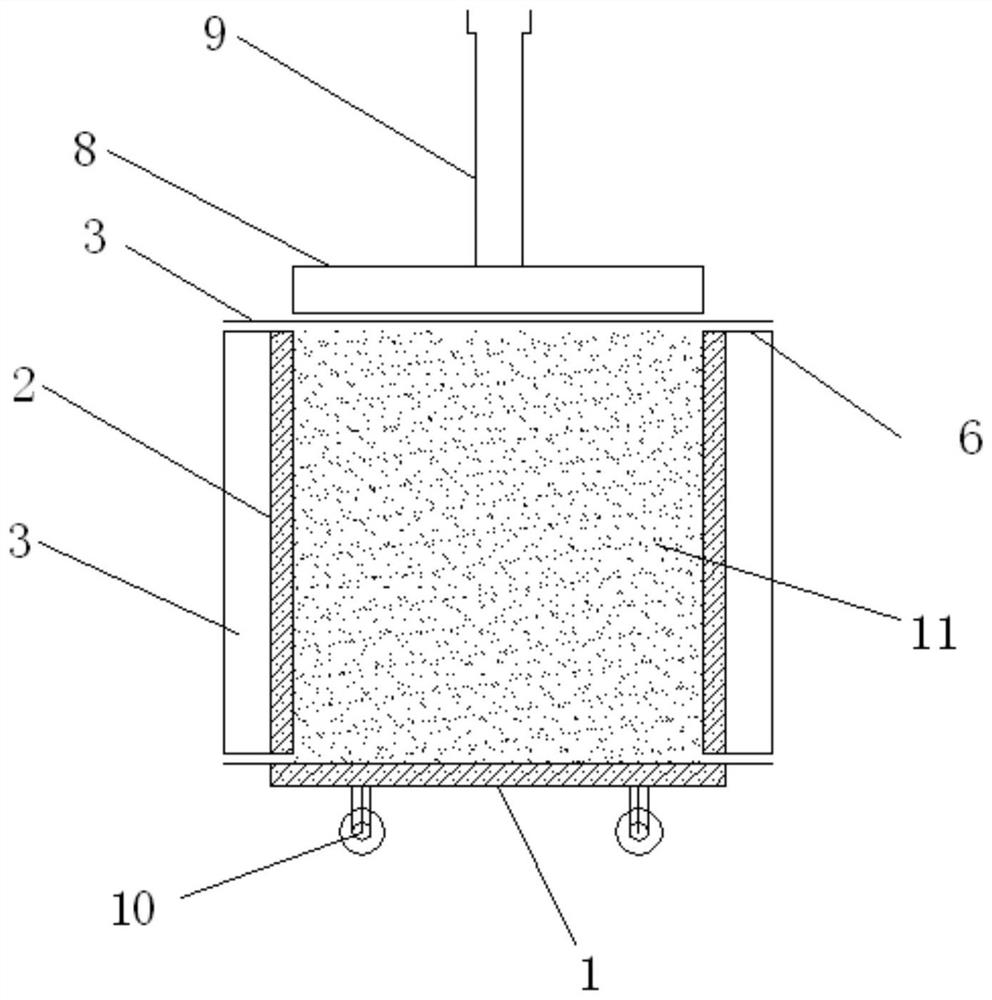

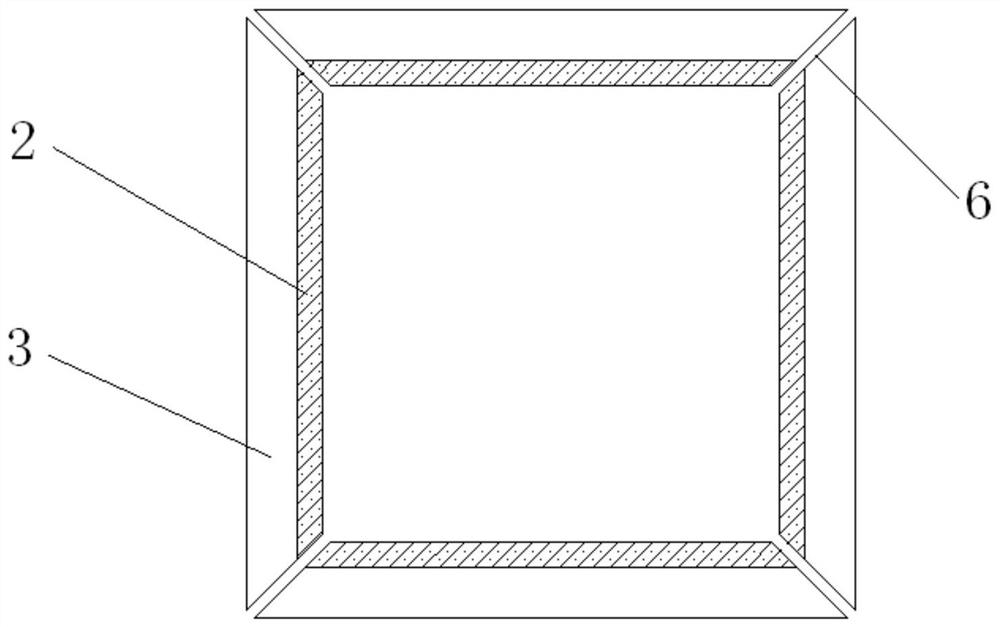

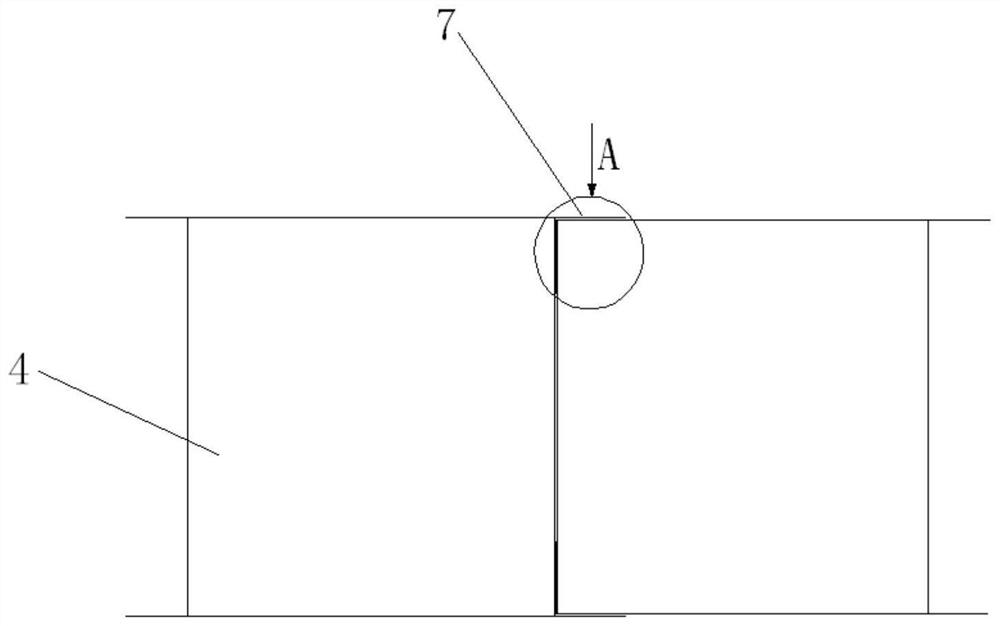

[0026] A method for treating fly ash from waste incineration of the present invention comprises the steps of chelating fly ash, extruding from movable silo and landfilling in sequence. Various materials such as fly ash, cement and chelating agent enter the compulsory mixer (silo capacity 6m) after being measured separately.3 ), the mixed material enters the extrusion process of the movable silo after being uniformly stirred for 60s. In the extrusion process of the movable silo, the materials are loaded into the movable silo. Each wall of the movable silo is detachable, and each wall forms a cavity with a regular polyhedron structure, and the inner wall of each wall is provided with HDPE Double rough facial mask 3, in this embodiment specifically, as figure 1 and figure 2 As shown, the movable silo includes a bottom wall 1 and a plurality of side walls 2, and the bottom wall 1 and each side wall 2 are detachable, that is, between the bottom wall 1 and the side walls 2, the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com