High-conductivity polystyrene-polyethylene composite conductive material and preparation method thereof

A polystyrene, high-conductivity technology, applied in the field of composite conductive materials, can solve the problems of lower product performance, easy cracking, poor flame retardancy of composite conductive materials, etc., and achieve the effect of good product uniformity and increased flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is a high-conductivity polystyrene-polyethylene composite conductive material, including the following components in parts by weight:

[0047] 40 parts of polystyrene, 60 parts of polyethylene, 15 parts of carbon black, 1 part of lubricant, 3 parts of antioxidant, 2 parts of flame retardant, 1 part of plasticizer and 1 part of compatibilizer;

[0048] The high-conductivity polystyrene-polyethylene composite conductive material is prepared by the following steps:

[0049] S1: Mix the polystyrene, polyethylene, lubricants, antioxidants, flame retardants, plasticizers and compatibilizers evenly and then extrude them with a granulator;

[0050] S2: continue to add carbon black for granulation;

[0051] S3: each component is fully kneaded in a molten state and then extruded and cooled to pelletize to obtain the high-conductivity polystyrene-polyethylene composite conductive material;

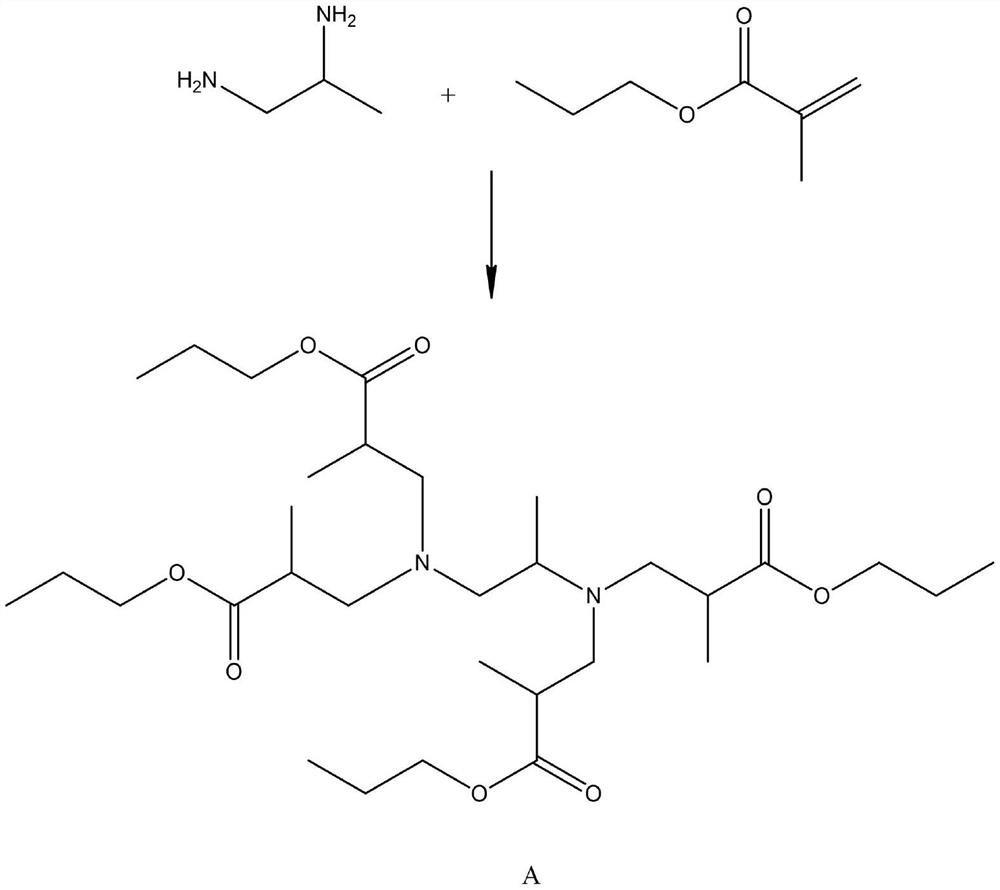

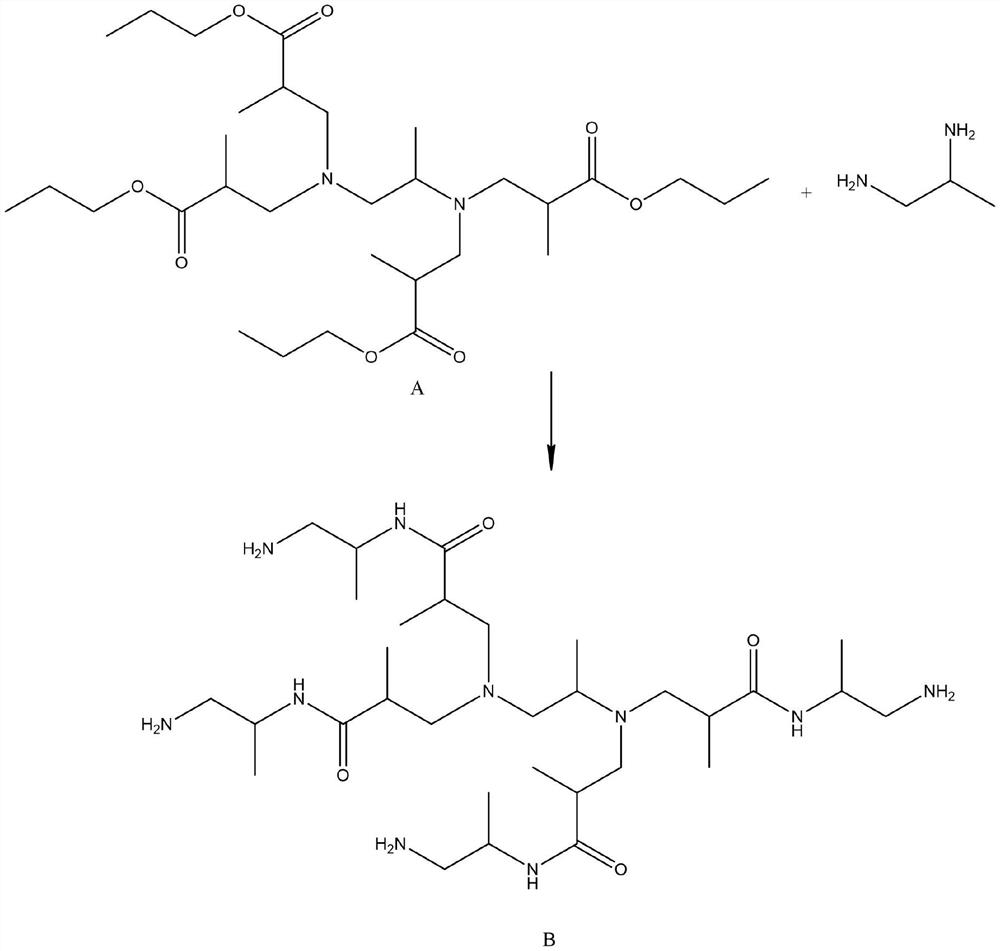

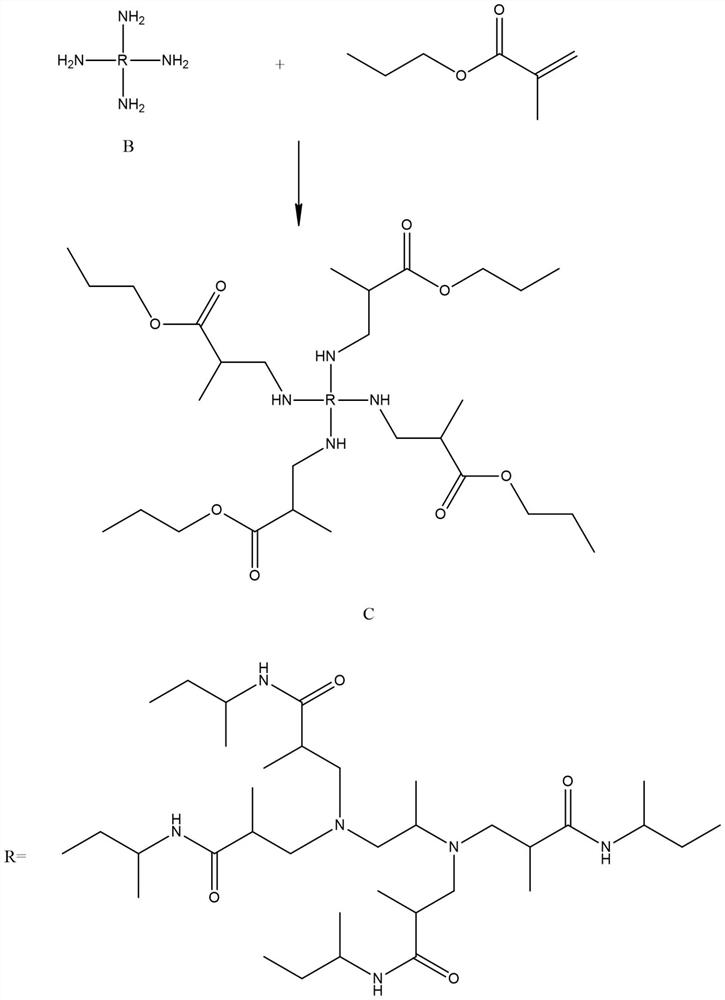

[0052] Antioxidants are prepared by the following steps:

[0053] S11: ...

Embodiment 2

[0062] This embodiment is a high-conductivity polystyrene-polyethylene composite conductive material, including the following components in parts by weight:

[0063] 40 parts of polystyrene, 80 parts of polyethylene, 15 parts of carbon black, 1 part of lubricant, 3 parts of antioxidant, 2 parts of flame retardant, 1 part of plasticizer and 1 part of compatibilizer;

[0064] The high-conductivity polystyrene-polyethylene composite conductive material is prepared by the following steps:

[0065] S1: Mix the polystyrene, polyethylene, lubricants, antioxidants, flame retardants, plasticizers and compatibilizers evenly and then extrude them with a granulator;

[0066] S2: continue to add carbon black for granulation;

[0067] S3: each component is fully kneaded in a molten state and then extruded and cooled to pelletize to obtain the high-conductivity polystyrene-polyethylene composite conductive material;

[0068] Antioxidants are prepared by the following steps:

[0069] S11: ...

Embodiment 3

[0078] This embodiment is a high-conductivity polystyrene-polyethylene composite conductive material, including the following components in parts by weight:

[0079] 50 parts of polystyrene, 80 parts of polyethylene, 30 parts of carbon black, 5 parts of lubricant, 6 parts of antioxidant, 6 parts of flame retardant, 5 parts of plasticizer and 3 parts of compatibilizer;

[0080] The high-conductivity polystyrene-polyethylene composite conductive material is prepared by the following steps:

[0081] S1: Mix the polystyrene, polyethylene, lubricant, antioxidant, flame retardant, plasticizer and compatibilizer evenly and then extrude it with a granulator;

[0082] S2: continue to add carbon black for granulation;

[0083] S3: each component is fully kneaded in a molten state and then extruded and cooled to pelletize to obtain the high-conductivity polystyrene-polyethylene composite conductive material;

[0084] Antioxidants are prepared by the following steps:

[0085] S11: Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com