Foamed polyphenyl ether polypropylene composite bead and wafer packaging box

A technology of polypropylene and polyphenylene ether, which is applied in the field of foamed polyphenylene ether polypropylene composite beads and wafer packaging boxes, can solve problems such as the difficulty in realizing the integrated design of wafer packaging boxes, and achieve automatic packaging solutions, Fewer consumables, realize the effect of integrated design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

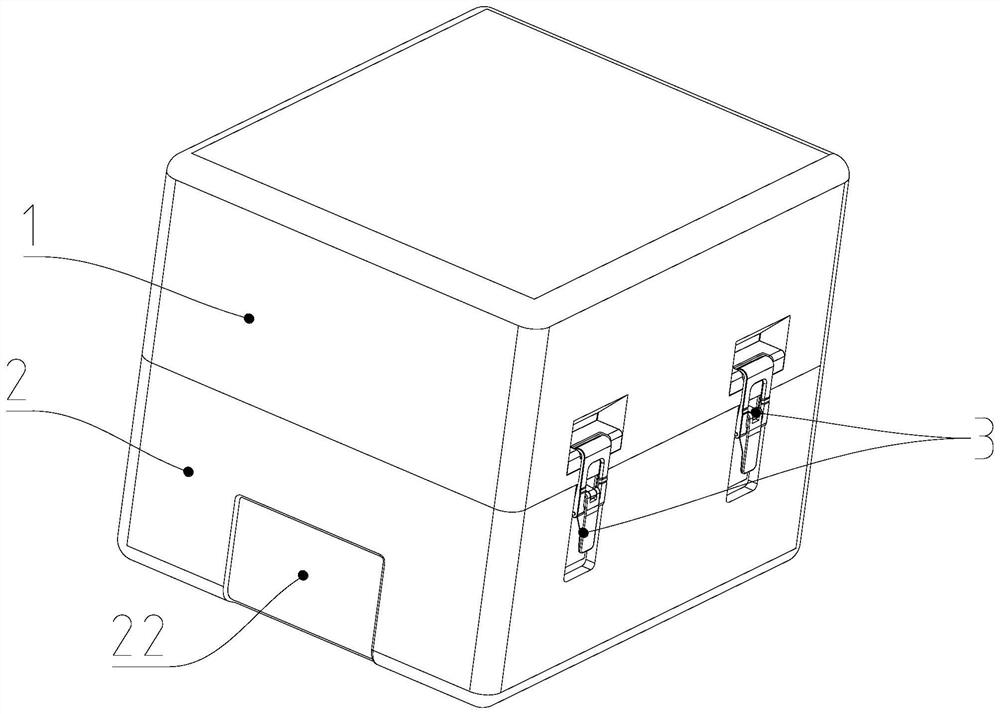

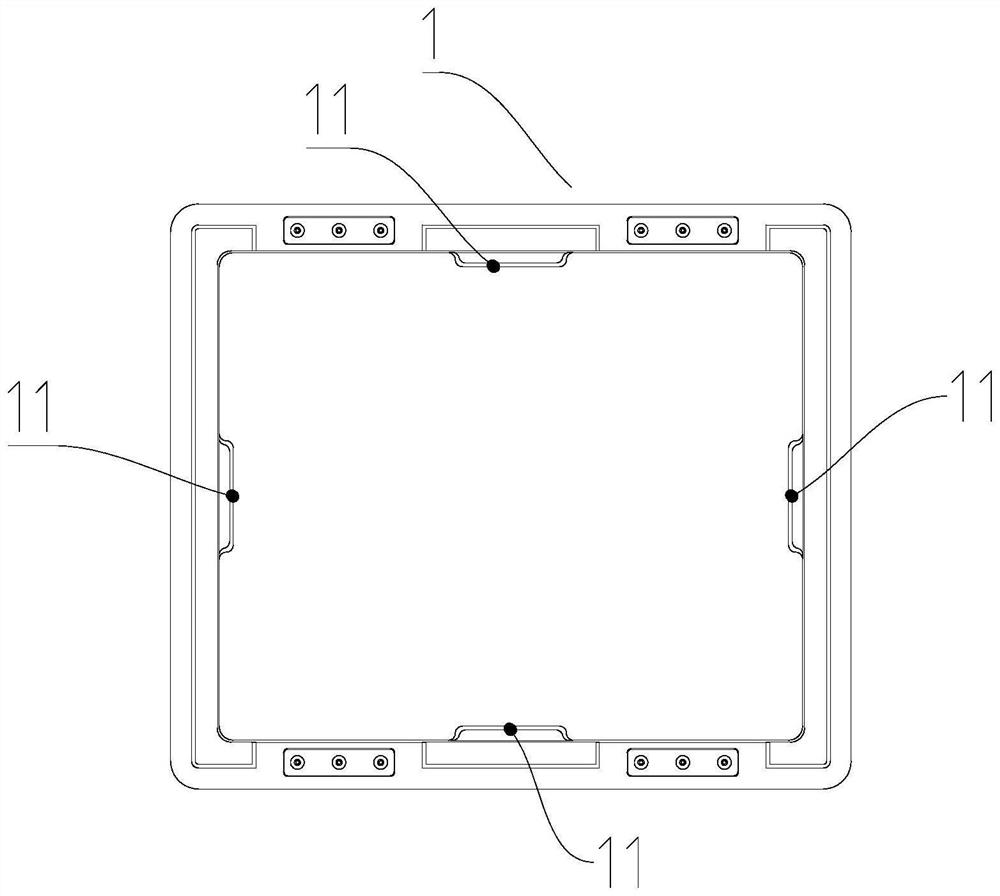

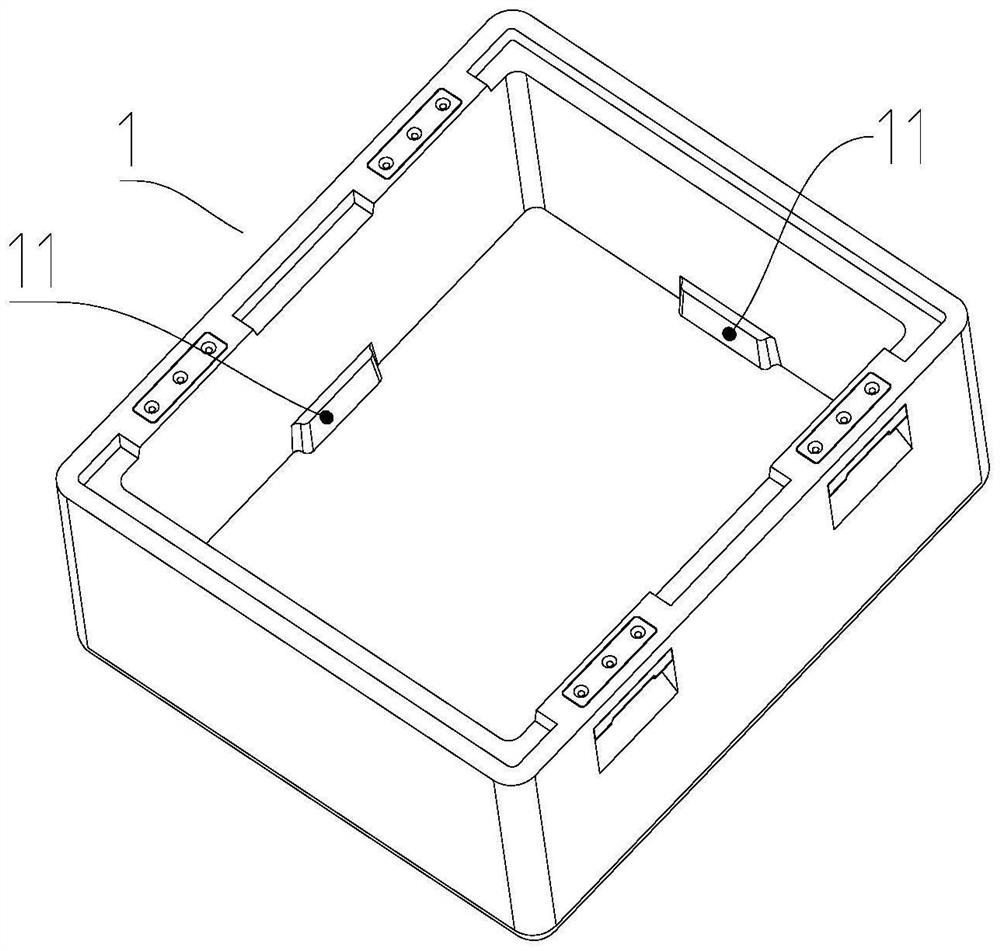

[0062] This embodiment provides a wafer packaging box, which is prepared from foamed polyphenylene ether polypropylene composite beads by steam molding; the foamed polyphenylene ether polypropylene composite beads are made of composite beads through physical Obtained by foaming; wherein the composite beads are composed of a core layer and a skin layer; the composite beads are prepared by co-extrusion composite granulation process, wherein the core layer processing screw temperature: 40 / 165 / 265 / 270 / 275 / 275 / 275 / 275 / 270 / 270 / 270 / 270, melt pressure: 2.1-2.3; skin processing screw temperature: 160 / 165 / 185 / 220 / 225 / 225 / 225 / 225 / 220 / 220 / 220 / 220, melt pressure : 2.2-2.5.

[0063] In parts by weight, the core layer includes the following components:

[0064]

[0065] The skin layer is polypropylene, the melting point is 149°C, and the melt index is 4-6g / 10min.

[0066] The thickness of the skin layer of the prepared composite beads is 12 μm, the diameter of the core layer is 1.5 mm,...

Embodiment 2

[0071] The difference between this embodiment and Embodiment 1 is:

[0072] In parts by weight, the core layer includes the following components:

[0073]

[0074]

[0075] The performance of the prepared wafer packaging box was tested, and the data are shown in Table 1.

Embodiment 3

[0077] This embodiment provides a wafer packaging box, which is prepared from foamed polyphenylene ether polypropylene composite beads by steam molding; the foamed polyphenylene ether polypropylene composite beads are made of composite beads through physical Obtained by foaming; wherein the composite beads are composed of a core layer and a skin layer; the composite beads are prepared by co-extrusion composite granulation process, wherein the core layer processing screw temperature: 40 / 165 / 265 / 270 / 275 / 275 / 275 / 275 / 270 / 270 / 270 / 270, melt pressure: 2.1-2.3; skin processing screw temperature: 160 / 165 / 185 / 220 / 225 / 225 / 225 / 225 / 220 / 220 / 220 / 220, melt pressure : 2.0-2.2.

[0078] In parts by weight, the core layer includes the following components:

[0079]

[0080] The skin layer is polypropylene with a melting point of 145°C and a melt index of 5-7g / 10min.

[0081] The thickness of the skin layer of the prepared composite beads is 13 μm, the diameter of the core layer is 1.3 mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com