Premixed mortar thin plastering construction method

A ready-mixed mortar and thin plastering technology, which is applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve problems such as inability to guarantee quality, non-standard construction, and large floor space, and achieve the benefits of civilization and safety, not easy to hollow and crack, avoiding the effect of occupying land and raising dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

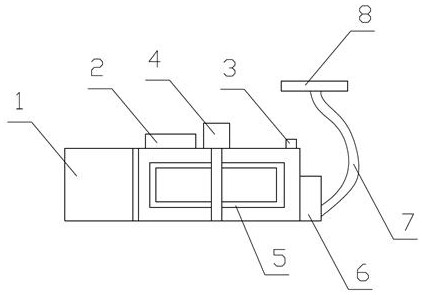

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

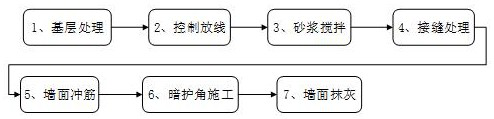

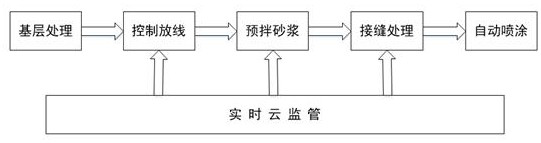

[0030] combined with figure 2 and attached image 3 , a thin plastering construction method of ready-mixed mortar, which comprises the following steps:

[0031] The first step is basic treatment. Before plastering, workers will remove the dust and debris on the surface of the wall. If the surface of the block is defective, it will be repaired with waterproof filler.

[0032] The second step is to control the payout, and use a laser to control the flatness, squareness and verticality of the wall to ensure that the size of the construction site is consistent with the design size;

[0033] The third step, ready-mixed mortar, using dry-mixed mortar, adding water in proportion to the site and stirring by the machine before use;

[0034] The fourth step is joint treatment. When the mortar is stirred by the machine in the previous step, the operation of hanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com