Preparation method of artificial compound eye made of PDMS material

A compound eye and artificial technology, applied in the direction of instruments, optics, lenses, etc., can solve the problems of insufficient anti-fog ability, poor durability of artificial compound eye surface structure, and easy loss of hydrophobicity, etc., to achieve good durability, strong durability, good Effects on Imaging Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of PDMS material artificial compound eye, comprising the following main steps:

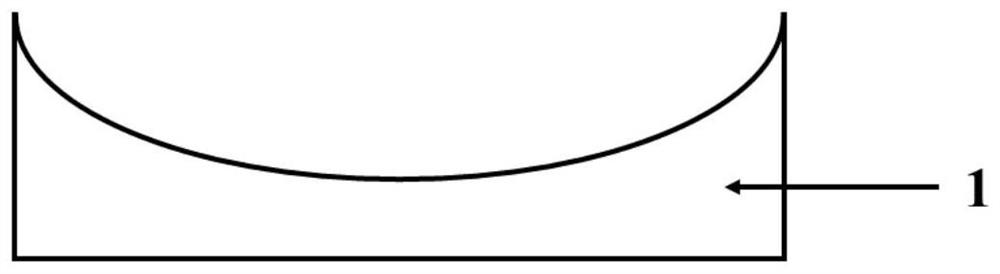

[0046] 1) Sample cleaning: figure 1 , figure 2 The curved K9 glass substrate shown is cleaned in an ultrasonic water bath with acetone, alcohol, and deionized water for 5 minutes in order to remove impurities on the surface of the curved K9 glass substrate, and then dried for use;

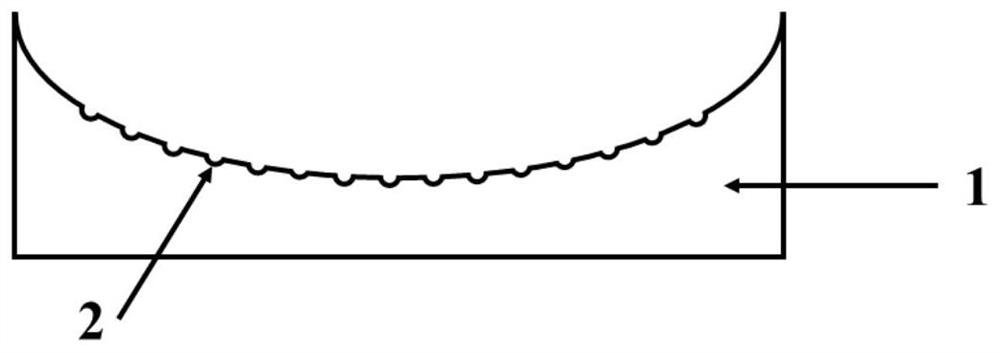

[0047] 2) Femtosecond laser modification: use a femtosecond laser beam with a center wavelength of 800nm, a pulse width of 50fs, a repetition frequency of 1KHz, and an energy of 5mW to focus on the surface of the curved K9 glass substrate through a 50-fold optical focusing lens, and the curved K9 glass substrate It is fixed on the three-dimensional translation stage, and the movement of the three-dimensional translation stage is controlled by the computer program. The action time of the femtosecond laser at each irradiation point is 500ms. The point-by-point scanning method is used to form...

Embodiment 2

[0052] A preparation method of PDMS material artificial compound eye, comprising the following main steps:

[0053] 1) Sample cleaning: Clean the curved K9 glass substrate with acetone, alcohol, and deionized water in an ultrasonic water bath for 5 minutes in order to remove impurities on the surface of the curved K9 glass substrate, and then dry it for later use;

[0054] 2) Femtosecond laser modification: use a femtosecond laser beam with a center wavelength of 800nm, a pulse width of 50fs, a repetition frequency of 1KHz, and an energy of 10mW to focus on the surface of the curved K9 glass substrate through a 50-fold optical focusing lens. It is fixed on the three-dimensional translation stage, and the movement of the three-dimensional translation stage is controlled by the computer program. The action time of the femtosecond laser at each irradiation point is 500ms. The point-by-point scanning method is used to form an orderly arrangement on the surface of the curved K9 glas...

Embodiment 3

[0059] A preparation method of PDMS material artificial compound eye, comprising the following main steps:

[0060] 1) Sample cleaning: Clean the curved K9 glass substrate with acetone, alcohol, and deionized water in an ultrasonic water bath for 5 minutes in order to remove impurities on the surface of the curved K9 glass substrate, and then dry it for later use;

[0061] 2) Femtosecond laser modification: use a femtosecond laser beam with a center wavelength of 800nm, a pulse width of 50fs, a repetition frequency of 1KHz, and an energy of 8mW to focus on the surface of the curved K9 glass substrate through a 50x optical focusing lens, and the curved K9 glass substrate It is fixed on the three-dimensional translation stage, and the movement of the three-dimensional translation stage is controlled by the computer program. The action time of the femtosecond laser at each irradiation point is 500ms. The point-by-point scanning method is used to form an orderly arrangement on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com