Off-line cleaning system and off-line cleaning method for water treatment membrane

A technology for water treatment membranes and cleaning systems, applied in separation methods, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of affecting the service life of membranes, attenuation of desalination performance, and high cost of cleaning agents, achieving low cost and recovery. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

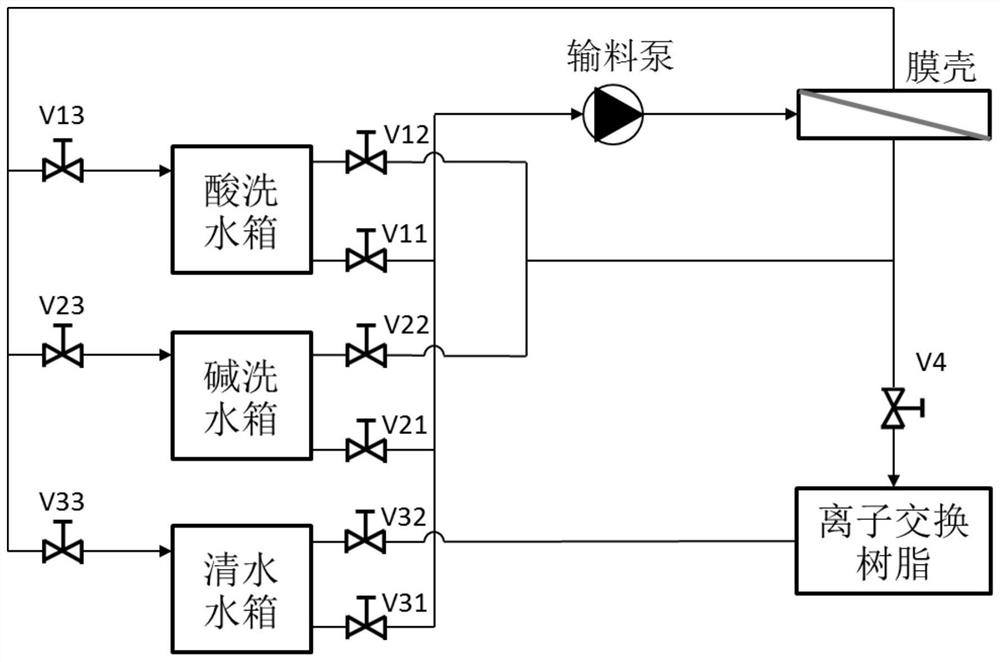

[0103] like figure 1 As shown, the offline cleaning system in Example 1 includes:

[0104] Clear water tank, feed pump, membrane shell, ion exchange resin column (anion resin column and cation resin column are connected in series, among which, the anion exchange resin column is filled with D201 macroporous strong acid anion exchange resin (similar products include AmberliteIRA-900 in the United States, Lewatit MP in Germany) -500, etc.), the cation exchange resin column is filled with D001 (similar products include Amberlite 200 in the United States, Lewatit SP-120 in Germany, etc.), and the ion exchange resin is transformed into a Cl-type anion resin through conventional pretreatment and transformation. The exchange resin is transformed into Na-type resin, and the pretreatment and transformation of resin is the industry standard method), alkali washing tank and acid washing tank,

[0105] Among them, the liquid outlet of the clean water tank, the liquid outlet of the alkali ...

Embodiment 2

[0118] The cleaning system in Example 2 is basically the same as that in Example 1, except that the ion exchange resin column in Example 1 is replaced by a water treatment membrane module with a model of Dow BW30-400, wherein the water treatment membrane module The produced concentrated water is mixed with the influent water of the wastewater treatment device in the factory area for treatment.

[0119] Using the cleaning system in Example 2 and cleaning the water treatment membrane to be cleaned in the manner in Example 1, and testing the cleaned water treatment membrane, it was found that the flux of the water treatment membrane element cleaned by the above steps From 90% to 99% of the standard flux of the product, the salt rejection rate is 99%.

Embodiment 3

[0121] The cleaning system in Example 3 is basically the same as that in Example 1, except that a cationic ion exchange resin column is used instead of the series-connected anion exchange resin column and cationic exchange resin column in Example 1.

[0122] The cleaning system in Example 3 was used to clean the water treatment membrane to be cleaned according to the method in Example 1, and the cleaned water treatment membrane was tested. It was found that the flux of the cleaned water treatment membrane element changed from the product From 90% of the standard flux to 98%, the desalination rate reaches 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com