Flotation separation method for household garbage incineration fly ash

A technology of domestic waste incineration and separation method is applied in the field of flotation separation of domestic waste incineration fly ash to achieve the effects of low cost, promotion of flotation separation, and improvement of flotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

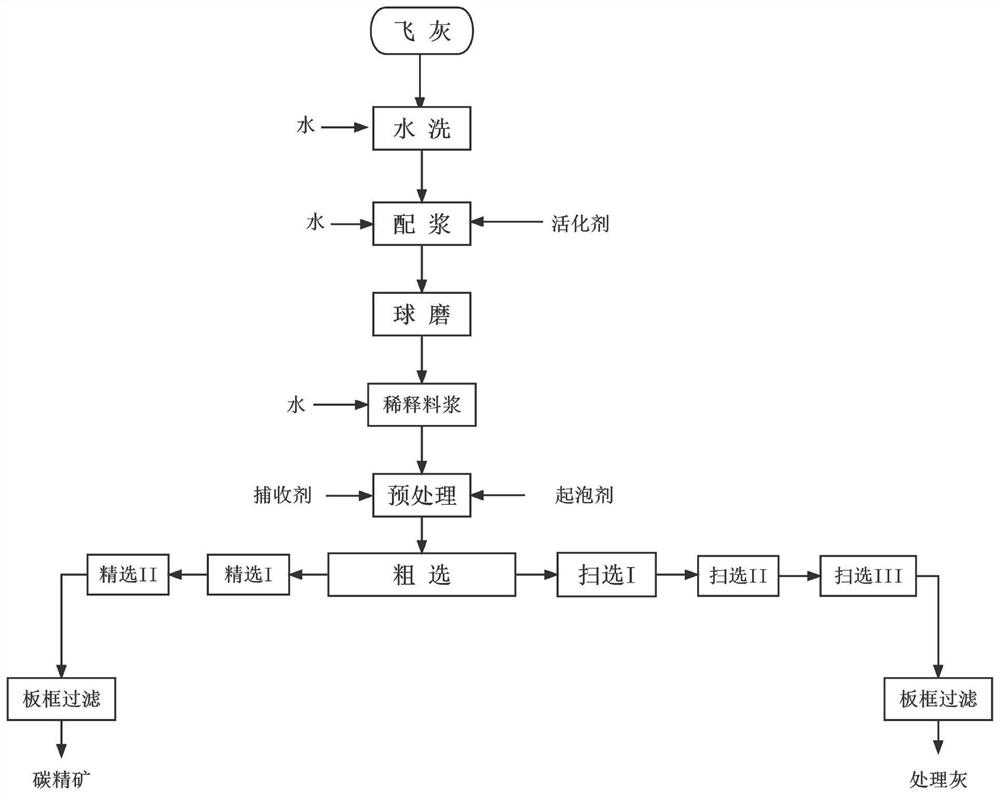

[0030] like figure 1 As shown, a flotation separation method of domestic waste incineration fly ash, the treated fly ash is domestic waste incineration fly ash from a waste incineration power plant in Guangdong, the soluble chlorine content in the fly ash is 16.83%, the activated carbon content is 2.50%, dioxin The British content is 350ng-TEQ / kg, and the process steps are:

[0031] (1) Washing of fly ash: 0.50t of waste incineration fly ash with a salt content of 40% is washed with four-stage water to obtain 0.48t of washed ash with a moisture content of 38% and a brine with a concentration of 18%. The mass ratio of fly ash and washing water in each level of fly ash washing is 1:2. The desalination rate of the first-level washing can reach 92%, and the desalination rate of the second-level washing is increased to 95%. After the third-level washing The chloride ion content is reduced to 1% to 2%, and the soluble chloride ion content is reduced to 0.45% after the fourth stage ...

Embodiment 2

[0039] like figure 1 As shown in the figure, a flotation separation method of domestic waste incineration fly ash, the treated fly ash is domestic waste incineration fly ash from a waste incineration power plant in Guangdong, the soluble chlorine content in the fly ash is 18.83%, the activated carbon content is 1.84%, the dioxin The British content is 430ng-TEQ / kg, and the process steps are:

[0040] (1) Washing of fly ash: 0.50t of waste incineration fly ash with a salt content of 40% is washed with four-stage water to obtain 0.49t of washed ash with a moisture content of 38.50% and a brine with a concentration of 18.89%. The mass ratio of fly ash and washing water in each level of fly ash washing is 1:2. The desalination rate of the first-level washing can reach 92.25%, and the salt-removing rate of the second-level washing increases to 95.79%. After the third-level washing The chloride ion content is reduced to 1% to 2%, and the soluble chloride ion content is reduced to 0...

Embodiment 3

[0048] like figure 1 As shown, a flotation separation method of domestic waste incineration fly ash, the treated fly ash is domestic waste incineration fly ash from a waste incineration power plant in Guangdong, the soluble chlorine content in the fly ash is 19.05%, the activated carbon content is 2.55%, dioxin The British content is 510ng-TEQ / kg, and the process steps are:

[0049] (1) Washing of fly ash: 0.50t of waste incineration fly ash with a salt content of 40% is washed with four-stage water to obtain a water-washed ash with a moisture content of 38.50% and a brine with a concentration of 0.49t and 18.89%. The mass ratio of fly ash and washing water in each level of fly ash washing is 1:2. The desalination rate of the first-level washing can reach 92.25%, and the salt-removing rate of the second-level washing increases to 95.79%. After the third-level washing The chloride ion content is reduced to 1% to 2%, and the soluble chloride ion content is reduced to 0.33% afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com