Cutting equipment for machining automobile parts

A technology of auto parts and cutting equipment, which is applied in metal processing equipment, metal processing, shearing machine equipment, etc., can solve the problems of inability to feed steel pipes and reduce the practicability of the device, so as to facilitate transportation, improve practicability, and improve leveling degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

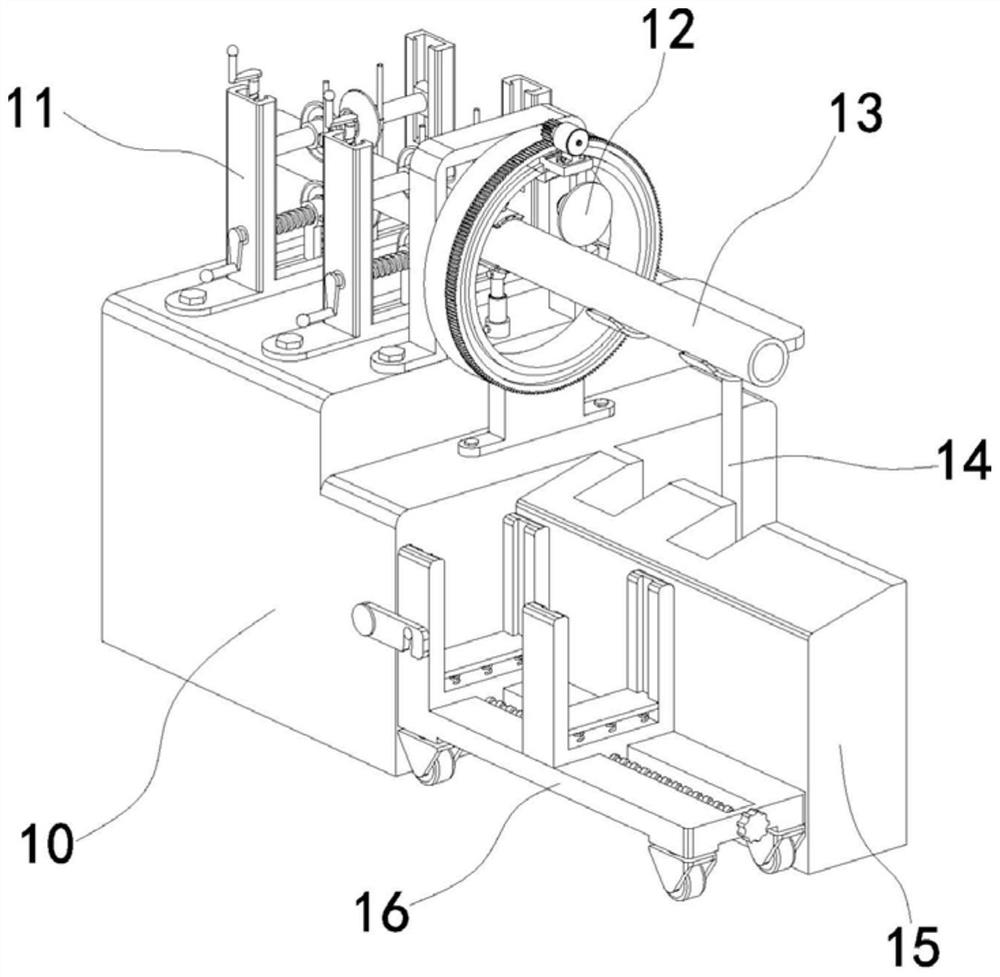

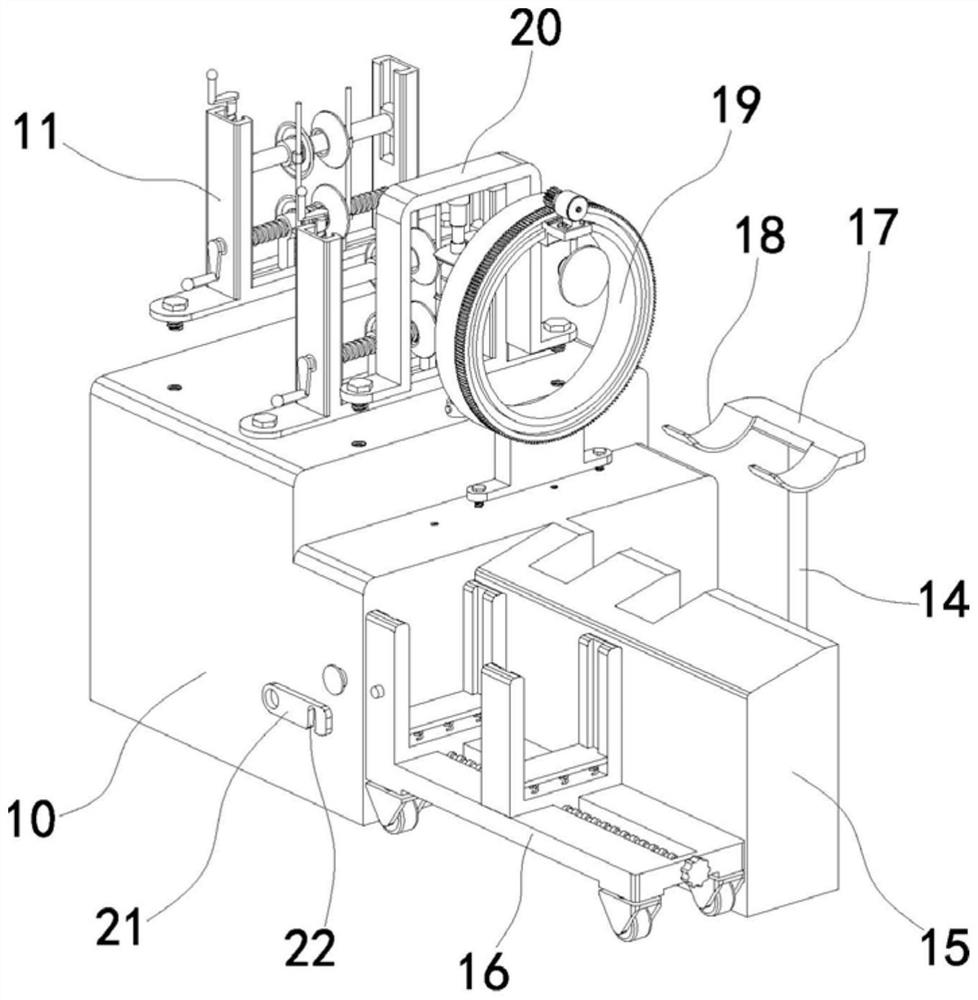

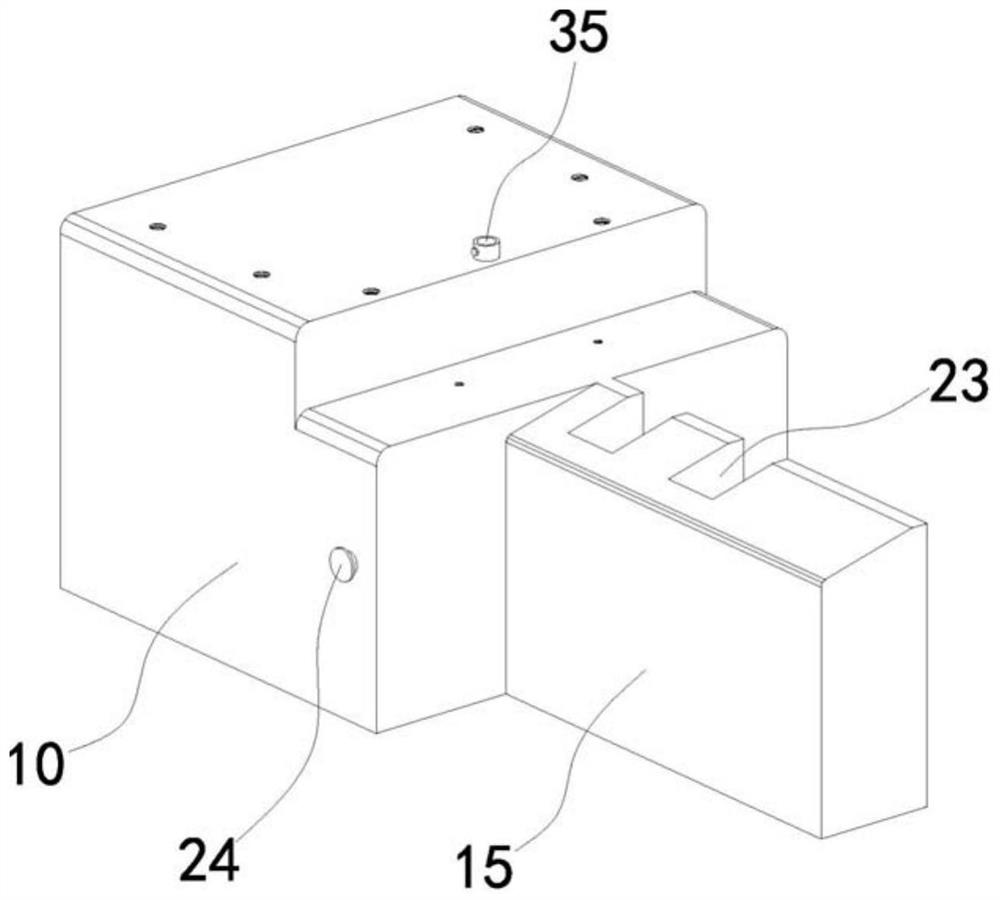

[0034] like Figure 1 to Figure 4 As shown, a cutting device for processing auto parts includes a workbench 10. Two sets of guide assemblies, fixing assemblies and cutting assemblies are arranged on the workbench 10 in sequence. The guide assemblies include a first mounting frame 11. The frame 11 is provided with a two-way screw 36 , two ends of the two-way screw 36 are respectively sleeved with threaded sleeves 39 , and the limit blocks 38 on the peripheral sides of the two sets of threaded sleeves 39 are clamped in the limit chute on the first mounting frame 11 . 37, the upper end of the first mounting frame 11 is provided with two sets of guide chutes 27 opposite to each other, and guide blocks 28 are respectively slidably arranged in the two sets of guide chutes 27, and the two sets of guide blocks 28 are connected by the connecting shaft 29, and the The two ends are respectively sleeved with connecting sleeves 30 , the guide rods 26 on the peripheral side of the two sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com