Modified nano zero-valent iron with core-shell structure as well as preparation method and application of modified nano zero-valent iron

A technology of nano-zero-valent iron and core-shell structure, which is applied in chemical instruments and methods, restoration of contaminated soil, water/sludge/sewage treatment, etc., can solve problems such as improving the reduction and removal efficiency of heavy metal ions, and is easy to provide Electrons, fast electron transfer rate, beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

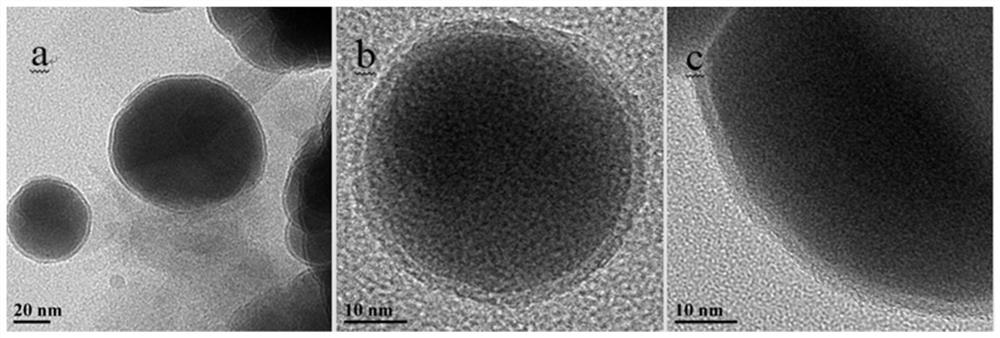

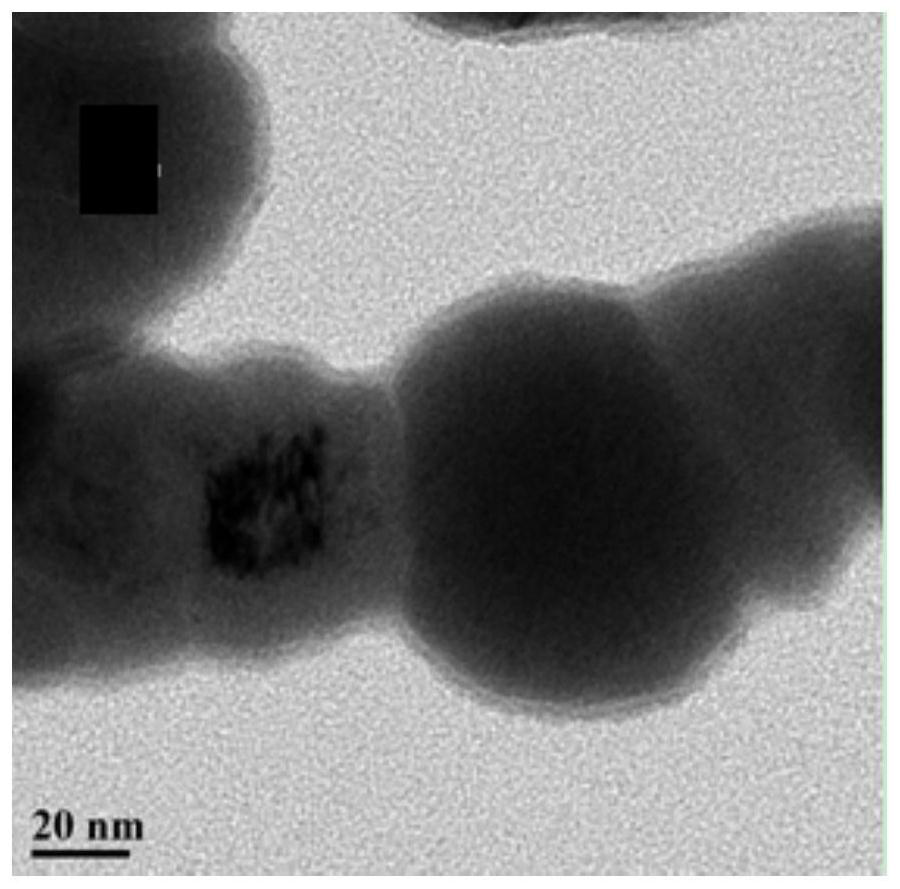

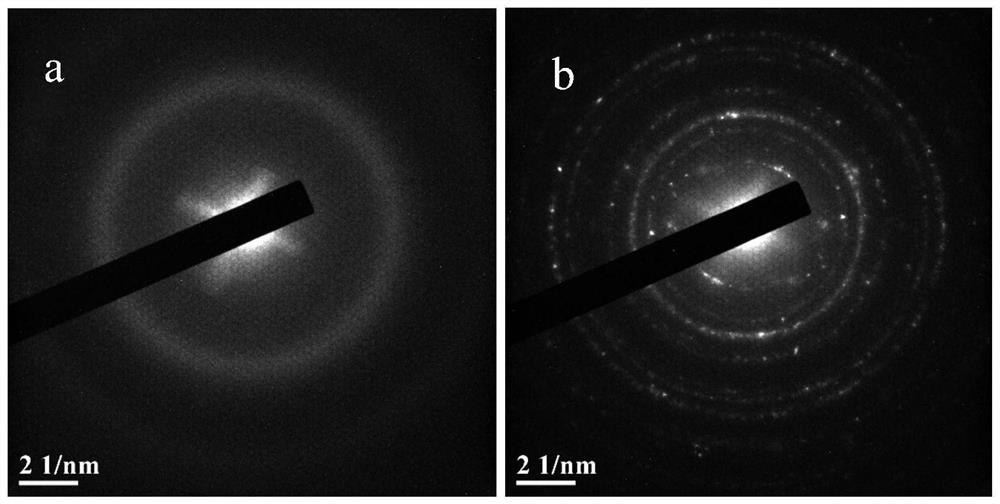

[0039] A preparation method of modified nano-zero valent iron with core-shell structure, comprising the following steps:

[0040] Under normal temperature and pressure, add 2.2700g of ferrous sulfate and 1.2g of 2-aminocyclohexanecarboxylic acid into the three-necked flask containing 200mL of ultrapure water, stir and mix for 5min to obtain a mixed solution; under normal temperature and pressure, in 100mL In the beaker, add 4.0000g potassium borohydride, 75mL ultrapure water, stir to dissolve, and mix well to obtain KBH 4 solution; at room temperature and normal pressure, the obtained KBH 4 The solution was added dropwise to the resulting mixed solution, the solution turned black and gradually formed particles, KBH 4 After the dropwise addition of the solution was completed, the reaction was stirred for 10 minutes, the solid-liquid was separated, washed, and freeze-dried at -60°C in a vacuum condition to obtain a modified nano-zero valent iron with a core-shell structure.

Embodiment 2

[0042] A preparation method of modified nano-zero valent iron with core-shell structure, comprising the following steps:

[0043] Under normal temperature and pressure, add 3.5600g of ferrous sulfate and 1.8g of 2-aminocyclohexanecarboxylic acid into a three-necked flask containing 250mL of ultrapure water, stir and mix for 10min to obtain a mixed solution; Add 4.6000g potassium borohydride, 80mL ultrapure water, stir to dissolve, and mix well to obtain KBH 4 solution; at room temperature and normal pressure, the obtained KBH 4 The solution was added dropwise to the resulting mixed solution, the solution turned black and gradually formed particles, KBH 4 After the dropwise addition of the solution was completed, the reaction was stirred for 13 minutes, the solid-liquid was separated, washed, and freeze-dried at -55°C in a vacuum condition to obtain a modified nano-zero valent iron with a core-shell structure.

Embodiment 3

[0045] A preparation method of modified nano-zero valent iron with core-shell structure, comprising the following steps:

[0046] Under normal temperature and pressure, add 4.5400g of ferrous sulfate and 2.4g of 2-aminocyclohexanecarboxylic acid into a three-necked flask containing 300mL of ultrapure water, stir and mix for 15min to obtain a mixed solution; under normal temperature and pressure, in 100mL Add 5.0000g potassium borohydride, 100mL ultrapure water, stir to dissolve, and mix well to obtain KBH 4 solution; at room temperature and normal pressure, the obtained KBH 4 The solution was added dropwise to the resulting mixed solution, the solution turned black and gradually formed particles, KBH 4 After the dropwise addition of the solution was completed, the reaction was stirred for 15 minutes, the solid-liquid was separated, washed, and freeze-dried at -50°C in a vacuum condition to obtain a modified nano-zero valent iron with a core-shell structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com