Low-temperature valve and production line thereof

A low-temperature valve and production line technology, applied in the direction of heat preservation, valve device, valve details, etc., can solve the problems of human hazards, large product shape and volume, etc., and achieve the effect of reducing self-weight, light weight and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

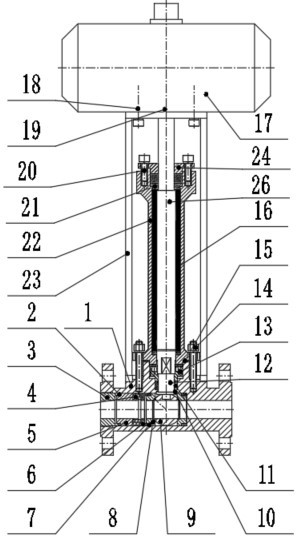

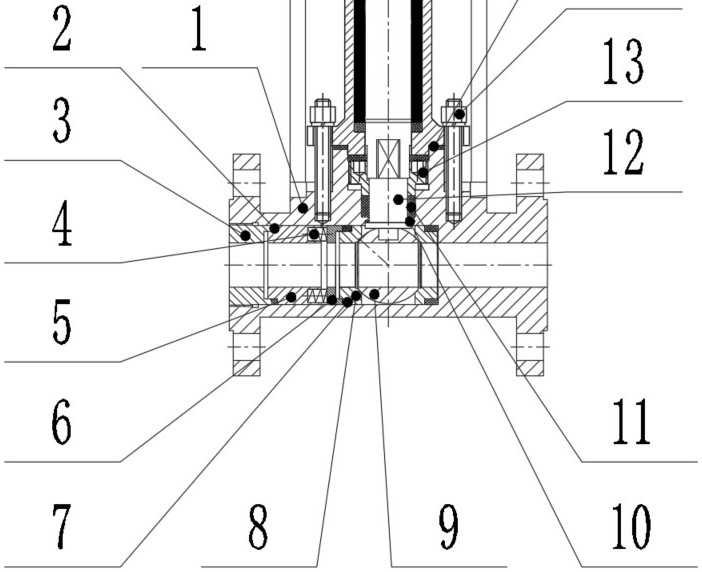

[0034] like figure 2 and image 3 shown, cryogenic valve, including valve body, opening and closing parts, valve seat, valve stem, long neck bonnet and packing gland;

[0035] The valve seat is installed in the valve body, the opening and closing member is installed in the valve seat, the opening and closing member is connected with the lower end of the valve stem in a transmission connection, and the valve stem is rotatably inserted in the whole. Inside the long-necked valve cover; the valve body is provided with a valve stem mounting seat with an overall upward convex cylindrical structure, and the lower end of the long-necked valve cover is coaxially fixed at the valve stem mounting seat; The top of the long-neck valve cover is fixedly installed with the packing press sleeve, the packing press sleeve is sleeved outside the upper section of the valve ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com