Circuit board etching method

A circuit board and etching solution technology, which is applied in chemical/electrolytic methods to remove conductive materials, printed circuits, printed circuit manufacturing, etc., can solve problems such as unstable fixation, side erosion, and inability to fix circuit boards, etc., to achieve fixed Good effect, improved etching quality, fast fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

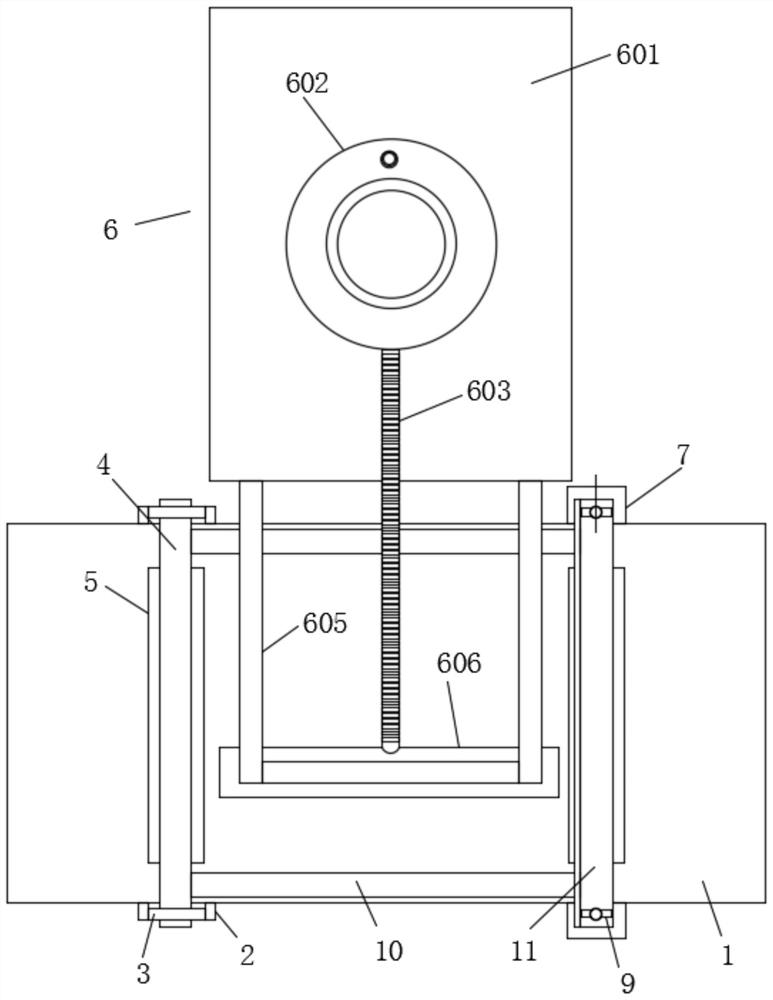

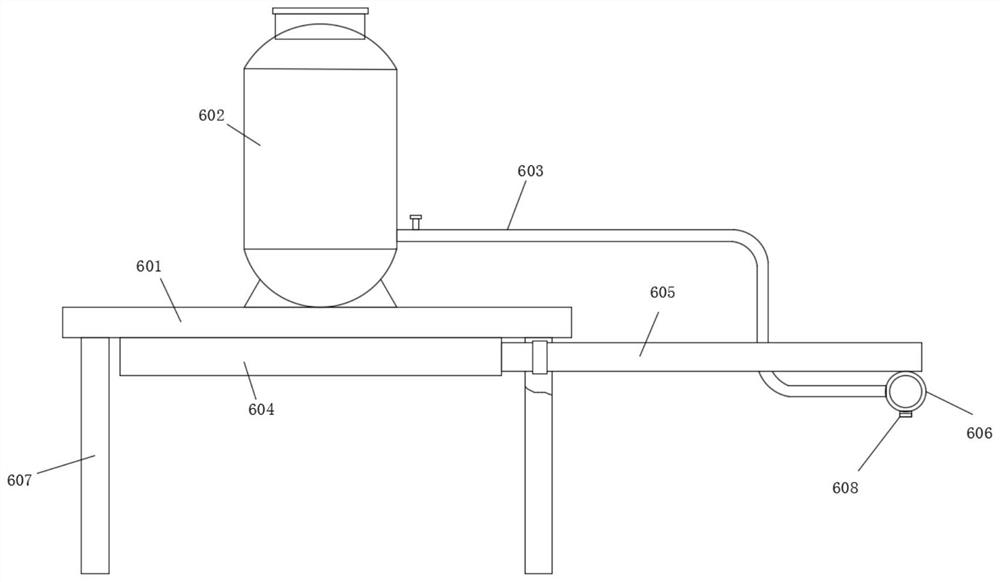

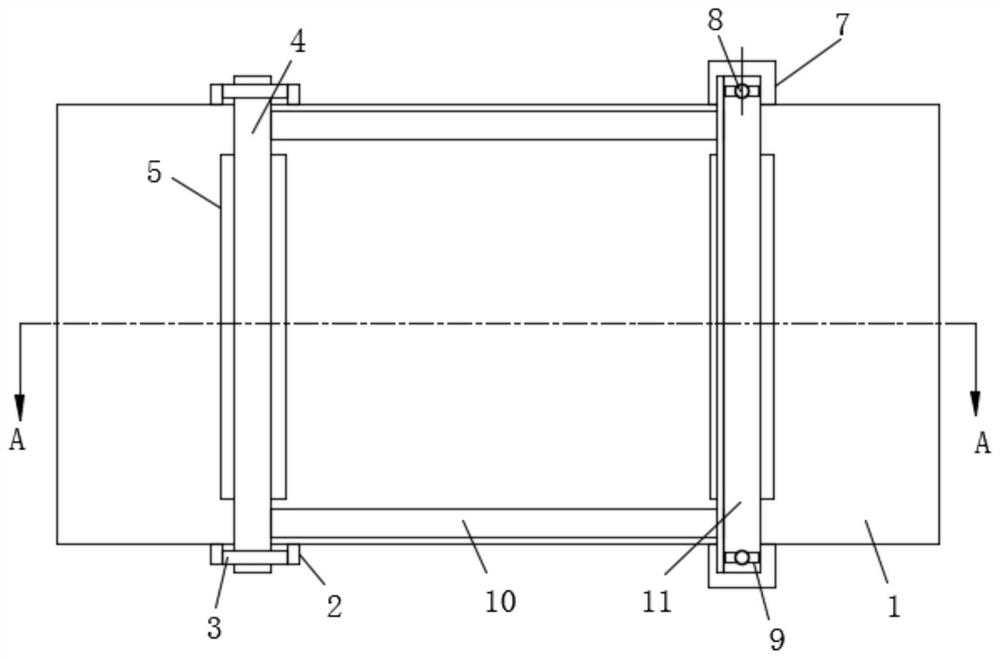

[0034] refer to Figure 1-Figure 7 , A circuit board etching device, comprising a first workbench 1, a rotary damping member 4 arranged along the width direction of the first workbench 1 is rotatably installed on the upper left side of the first workbench 1, and two parts of the rotary damping member 4 are rotatably installed. The end is rotated and installed on the connecting part 3, and then the connecting part 3 is fixed on the first worktable 1 through the fixing part 2. The right side of the rotation damping member 4 is fixed with an elongated fixing member 10 perpendicular to the rotation damping member 4 , the other end of the long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com