Beverage bottling facility

A bottling and beverage technology, applied in the field of beverage bottling facilities, can solve the problems of increasing the complexity of installation and maintenance, complicated installation design, and no disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

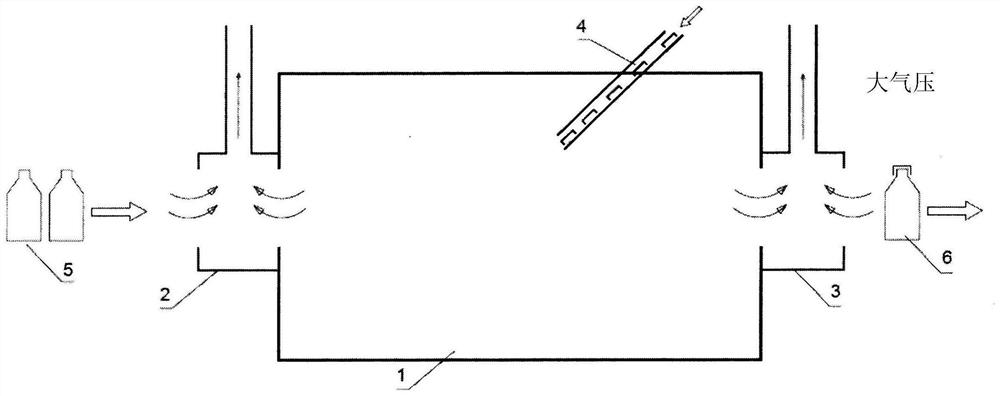

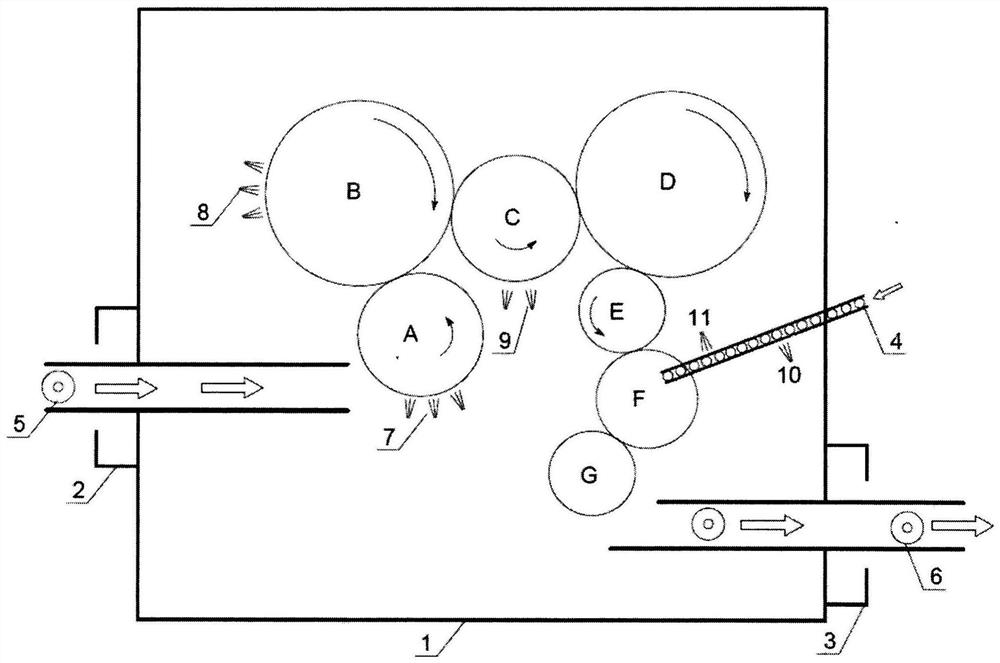

[0039] Composition of proposed objects.

[0040] 1. The outer wall (single) of the facility.

[0041] 2. The hood at the inlet of the monomer (arrows show the movement of the airflow).

[0042] 3. The hood at the outlet of the monomer (the arrows show the movement of the airflow).

[0043] 4. Feed the cap into the monomer (the arrow shows the direction of movement of the cap).

[0044] 5. Feed the empty container into the monomer (arrows show the direction of movement of the container).

[0045] 6. Remove the filled and capped container from the monomer (arrows show the direction of movement of the container).

[0046] 7. The nozzle on Star A treats the vessel with the finely dispersed hydrogen peroxide mixture.

[0047] 8. Nozzle on star B to treat container with fine hydrogen peroxide mixture.

[0048] 9. The nozzles on star C treat the containers with hot sterile air immediately before sending them to the product produced on the filling carousel D.

[0049] 10. At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com