Preparation method and preparation system of catalytic cracking aid

A technology of catalytic cracking and additives, applied in catalytic cracking, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complex phosphorus modification process and complex preparation process of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

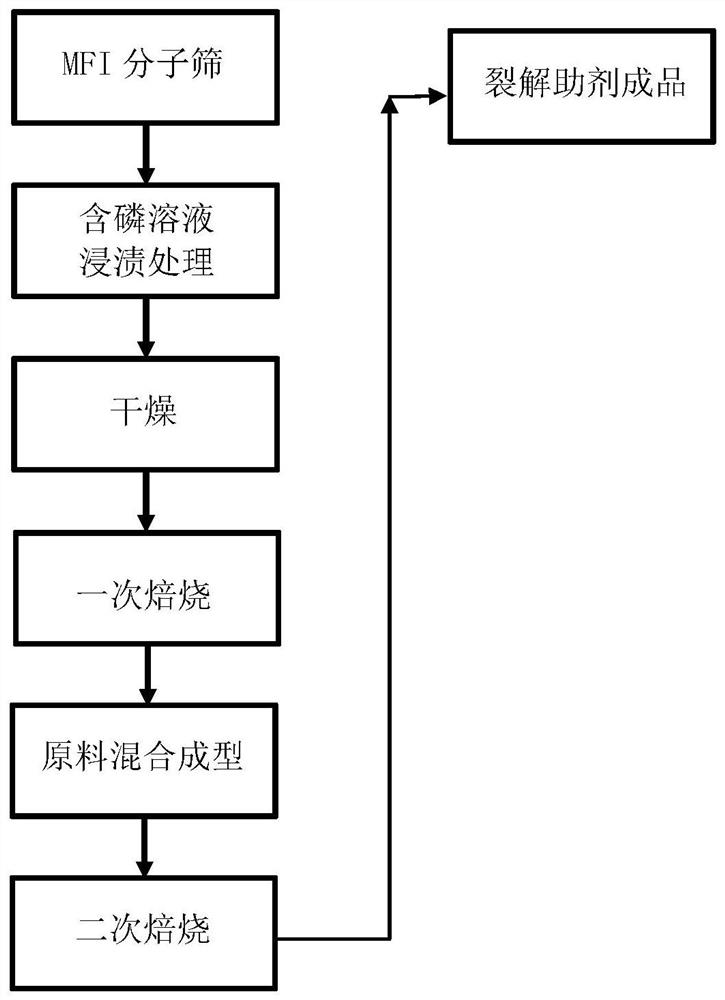

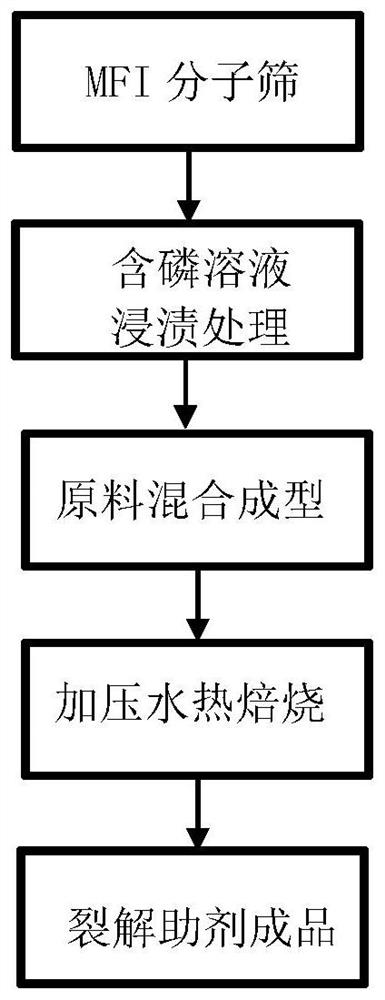

Method used

Image

Examples

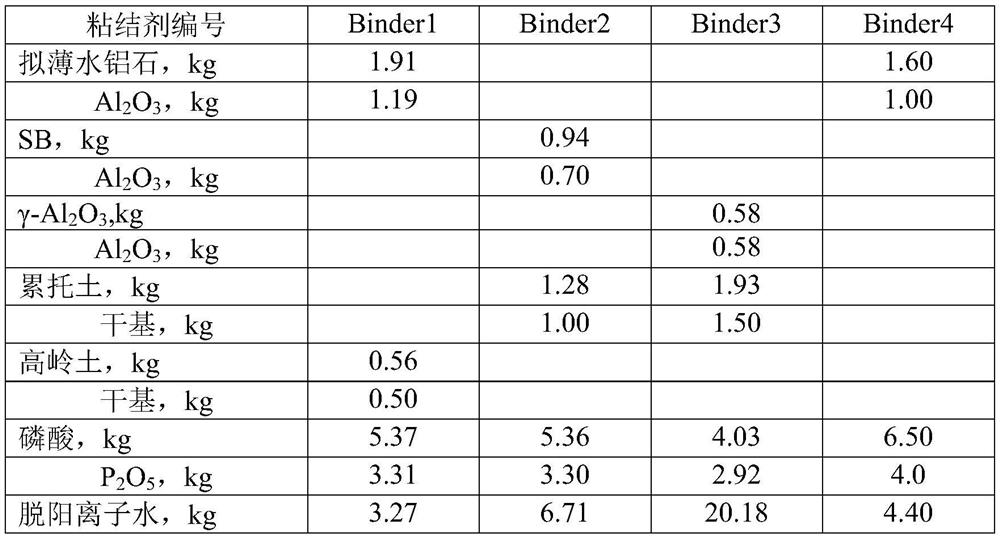

Embodiment 1-1

[0049] Dissolve 16.2 g of diammonium hydrogen phosphate (Tianjin Guangfu Technology Development Co., Ltd., analytically pure, the same below) in 60 g of deionized water, stir for 0.5 h to obtain a phosphorus-containing aqueous solution, add 113 g of HZSM-5 molecular sieve (Sinopec Catalyst Company Qilu Branch supplied with a relative crystallinity of 91.1%, a silica / alumina molar ratio of 24.1, Na 2 O content is 0.039wt%, specific surface area is 353m 2 / g, the total pore volume is 0.177ml / g, the same below), modified by impregnation method, impregnated at 20 °C for 2 hours, mixed with kaolin and pseudoboehmite, added decationized water and alumina sol Slurry for 120 minutes , obtain a slurry with a solid content of 30% by weight, add hydrochloric acid to adjust the pH value of the slurry to 3.0, and then continue to beat for 45 minutes, then add a phosphorus-aluminum inorganic binder Binder1, and stir for 30 minutes. , the microspheres were subjected to external pressure and...

Embodiment 1-2

[0055] The same as Example 1-1, the difference is that the phosphorus-modified molecular sieve mixes diammonium hydrogen phosphate, HZSM-5 molecular sieve and water into a slurry, and then heats it up to 100°C for 2h. A sample of catalytic cracking aid was prepared, numbered CEZ1-2. The evaluation is the same as that of Example 1-1, and the results are shown in Table 3.

Embodiment 2-1

[0062] Same as Example 1-1, the difference is that 16.2g of diammonium hydrogen phosphate was dissolved in 120g of deionized water at 50°C, stirred for 0.5h to obtain a phosphorus-containing aqueous solution, added with 113g of HZSM-5 molecular sieve, modified by impregnation method, Immersion at 20°C for 2 hours; external pressure is applied and water is added, and pressurized hydrothermal calcination is carried out at 600°C, 0.5Mpa, 30% steam atmosphere for 2h. A sample of catalytic cracking aid was prepared, numbered CEZ2-1.

[0063] The evaluation is the same as that of Example 1-1, and the results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com