Waste screening and cleaning equipment and cleaning method for mold processing factory

A technology for cleaning equipment and processing plants, which is applied to cleaning methods and appliances, chemical instruments and methods, and the removal of solid waste. It can solve problems such as easy injury, increased labor force, and increased economic costs, so as to increase activation energy and improve Derusting effect, avoiding the effect of floating around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

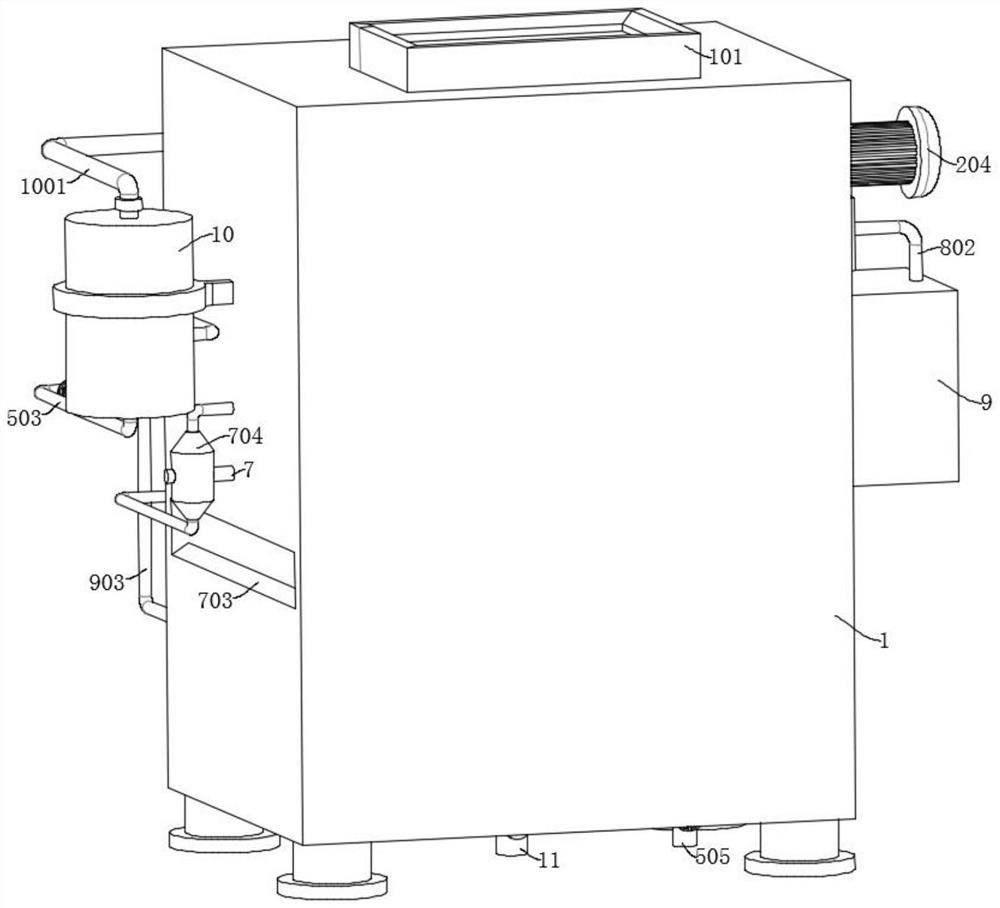

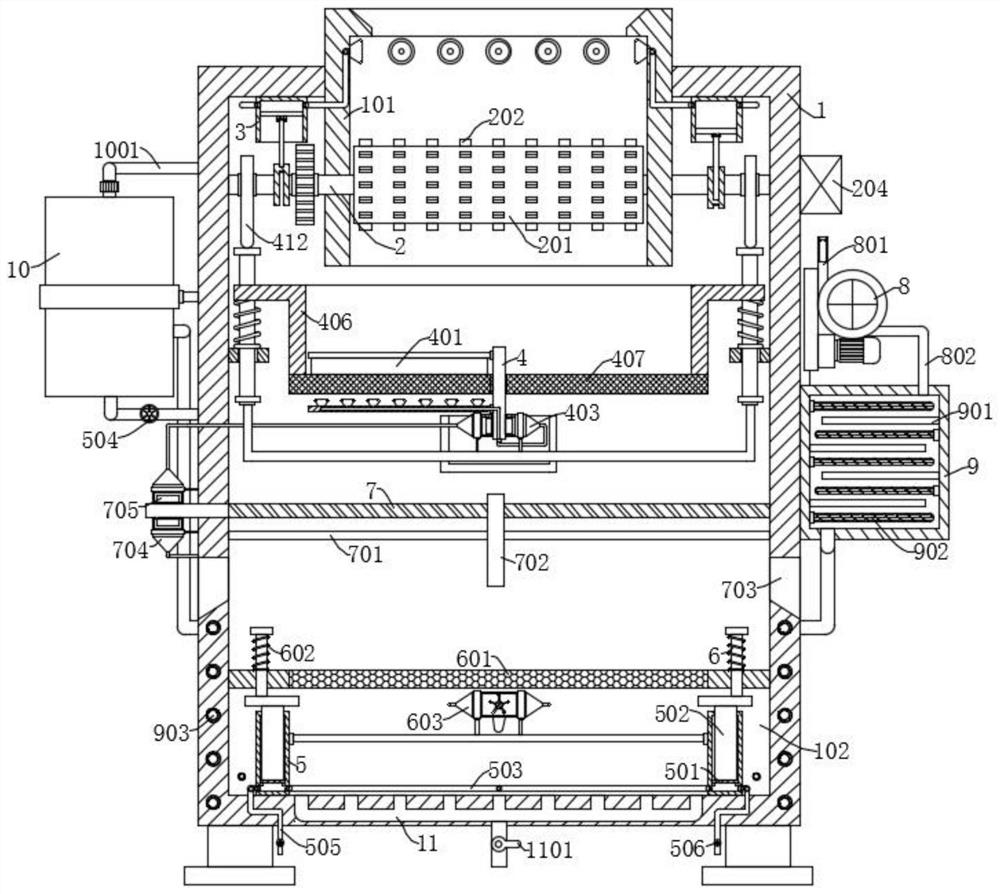

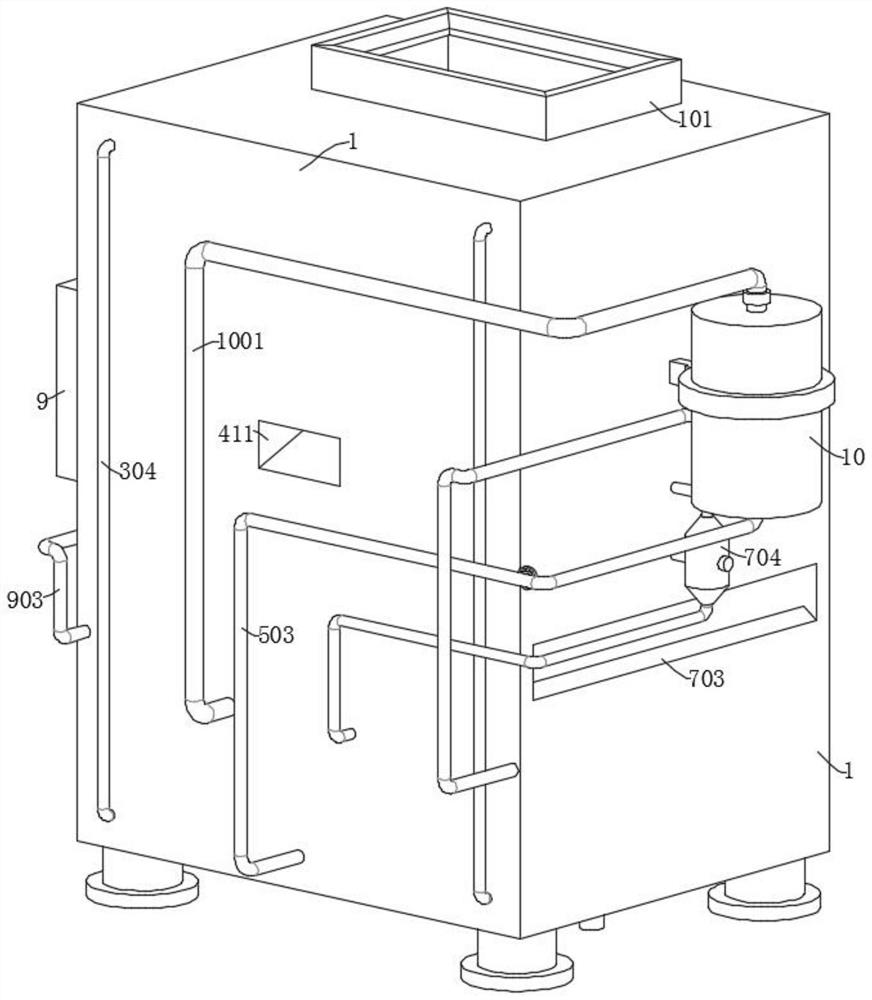

[0043] refer to Figure 1-Figure 10 , a waste screening and cleaning equipment for a mold processing plant, including a box body 1, and also includes: a processing box 101 and two sets of piston assemblies 3, all of which are fixedly connected to the top inner wall of the box body 1, wherein the box body 1 is provided with a cleaning In the cavity 102, the processing box 101 is provided with a crushing mechanism for crushing waste materials; two sets of crankshafts 301 are fixedly sleeved on the crushing mechanism and are rotatably connected with the two sets of piston assemblies 3; the dust collecting cover 303 is fixedly connected to the processing The inner wall of the box 101; the conduit one 302, one end of which is connected to the piston assembly 3, and the other end is connected to the dust collecting hood 303; the conduit two 304, one end of which is connected to the piston assembly 3, and the other end is connected to the cleaning chamber 102; the screening mechanism,...

Embodiment 2

[0056] refer to figure 2 , Image 6 , a waste screening and cleaning equipment used in a mold processing plant, which is basically the same as the embodiment 1. Further, the jacking mechanism includes a sleeve 5 and a piston disc 501 slidably connected in the sleeve 5. The piston disc 501 passes through The support rod 502 is fixedly connected with the support column 6, the sleeve 5 is fixedly connected with the second pipe 505, the sleeve 5 is communicated with the inner cavity of the gas storage tank 10 through the first pipe 503, and the first pipe 503 is connected with a solenoid valve one 504. The second solenoid valve 506 is connected to the second 505 , and the sleeve 5 is fixedly connected to the inner wall of the bottom of the box body 1 .

[0057]The drive assembly that drives the second scraper 702 to move includes a reciprocating screw 7 and a guide rod 701 fixedly connected to the inner wall of the box 1 . The second scraper 702 is slidably connected to the guid...

Embodiment 3

[0060] refer to figure 2 , Figure 10 , a waste screening and cleaning equipment for a mold processing plant, which is basically the same as the embodiment 1, and further, the inner wall of the heating box 9 is provided with multiple sets of interlaced partitions 901, and the multiple sets of partitions 901 are fixedly connected to the heating box. On the inner wall of 9, heating wires 902 are arranged between the adjacent two groups of partition plates 901; when the suction pump 8 extracts the external air through pipeline five 801, and then transports it into the heating box 9 through pipeline six 802 for heating, due to the multiple groups The partitions 901 are staggered and fixedly connected in the heating box 9, so that when the external air enters the heating box 9, the gas flow is S from top to bottom, and is matched with the heating wires 902 between the adjacent two sets of partitions 901. , so that the gas can be fully heated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com