Automatic machining process for new energy automobile brake calipers

A new energy vehicle and brake caliper technology, which is applied in the field of auto parts processing, can solve problems such as processing that cannot be automated, and achieve high processing efficiency, guaranteed product quality, and high sand core removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

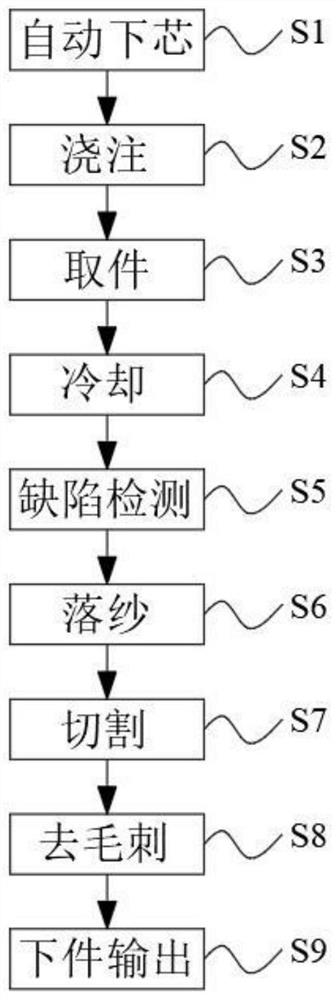

[0046] like figure 1 As shown, this embodiment provides an automated processing technology for a new energy vehicle brake caliper, which includes the following steps:

[0047] S1. Automatic core unloading: remove the sand core of the new energy vehicle brake caliper from the double-layer sand core table by the sand core robot and place it on the sand core mold of the gravity casting machine; among them, the specifications and models of the sand core robot It is R-2000IC / 165; the double-layer sand core table includes a double-layer shuttle table, and each layer of the shuttle table is placed with eight mold sand cores. The new energy vehicle brake caliper is a double-cylinder caliper;

[0048] S2. Pouring: A pouring robot equipped with a seven-axis pouring arm and a liquid taking and pouring mechanism is used to scoop the aluminum alloy melt from the crucible holding furnace, and pour it into the sand core mold of the gravity casting machine to obtain a semi-finished product; ...

Embodiment 2

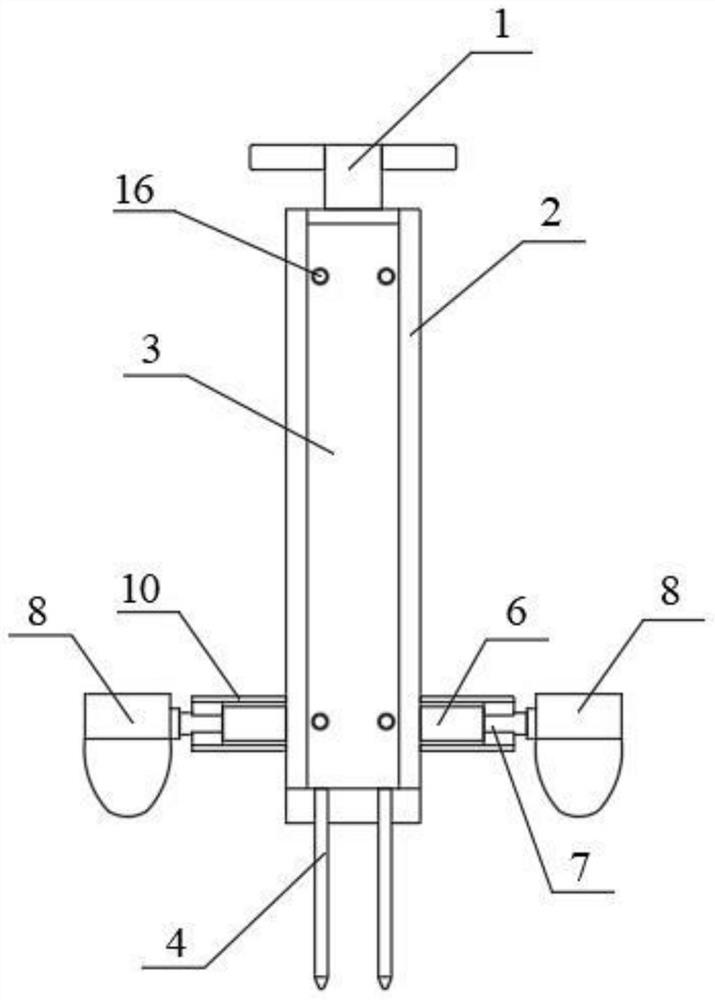

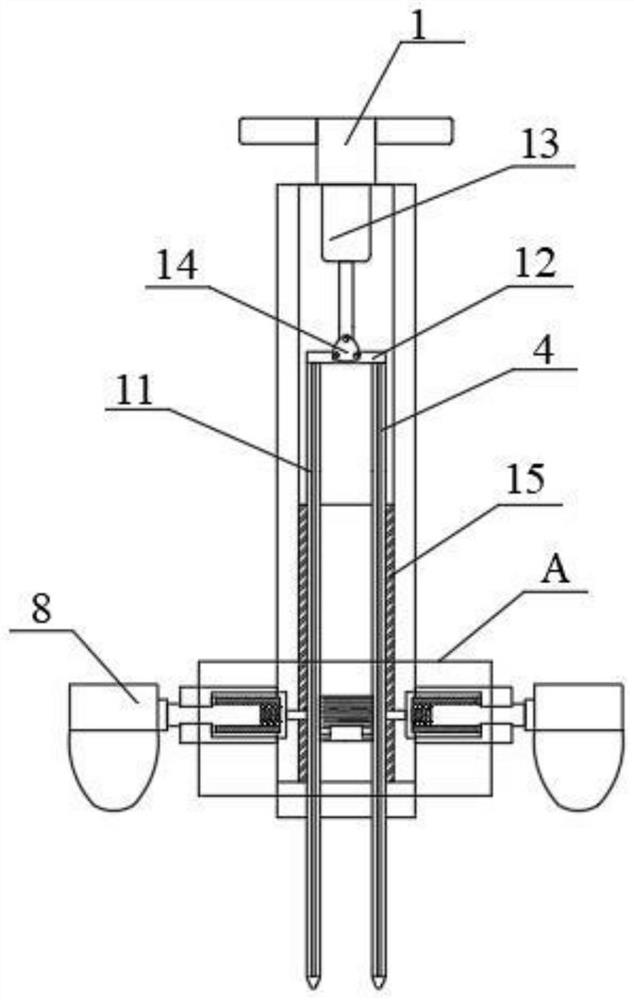

[0058] like Figure 2-5 As shown, this embodiment provides a liquid-taking and pouring mechanism, which is used for liquid level detection and liquid-taking and pouring of aluminum alloy melt after being assembled with a seven-axis pouring arm of a pouring robot, including an assembly head 1, a sampling box 2 and a sampling Cover 3, the assembly head 1 is fixed on the top of the sampling box 2, the sampling cover 3 is covered on the outside of the sampling box 2 and is fastened by bolts 16, the sampling box 2 is rotated and connected with a ladle mechanism near the bottom, and the sampling box 2 The inner cavity is provided with two detection pipes 4 extending out of the bottom of the sampling box 2 .

[0059] The ladle mechanism includes a biaxial motor 5, a casing 6, a rotary shaft 7 and a stainless steel ladle 8. The biaxial motor 5 is located in the inner cavity of the sampling box 2 near the bottom, and the motor shaft of the biaxial motor 5 extends toward both sides and ...

Embodiment 3

[0063] like Figure 6-7 As shown in the figure, this embodiment provides a sand hammer, which is used for high-frequency hammering during doffing to separate the sand core from the surface of the brake caliper cooling semi-finished product, crack it into pieces, and remove it by collapsing, including a frame 17 and a hammer box 18 and the waste sand collection chamber 19, the hammer box 18 and the waste sand collection chamber 19 are respectively arranged at the top and bottom of the frame 17, the hammer box 18 is provided with a soundproof room 20 inside, and the outside of the soundproof room 20 is equipped with a soundproof door 21 . The hammering box 18 is provided with a high-frequency hammering mechanism and an oscillating positioning mechanism.

[0064] Through the high-frequency hammering of the high-frequency hammering mechanism and the positioning oscillation of the oscillating positioning mechanism, the sand core and the surface of the brake caliper cooling semi-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com