Micro-current Fenton-like fluidized bed membrane reactor for treating refractory wastewater

A membrane reactor and reactor technology, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of poor cycle life, low electrode conversion efficiency, and easy falling off of the coating layer. , to achieve long cycle life, improve electron utilization, and avoid the loss of catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

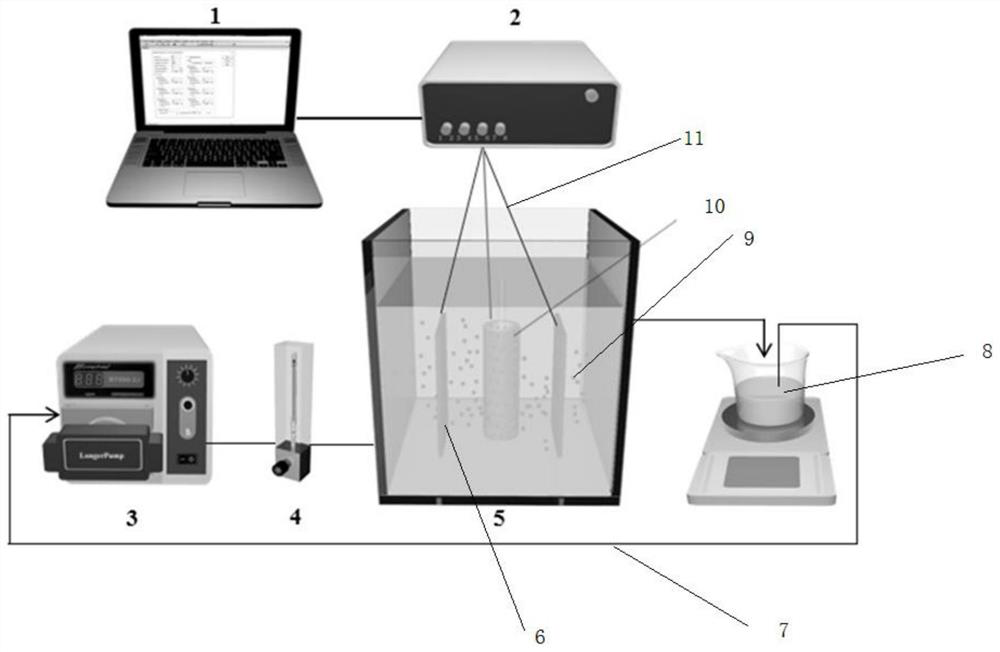

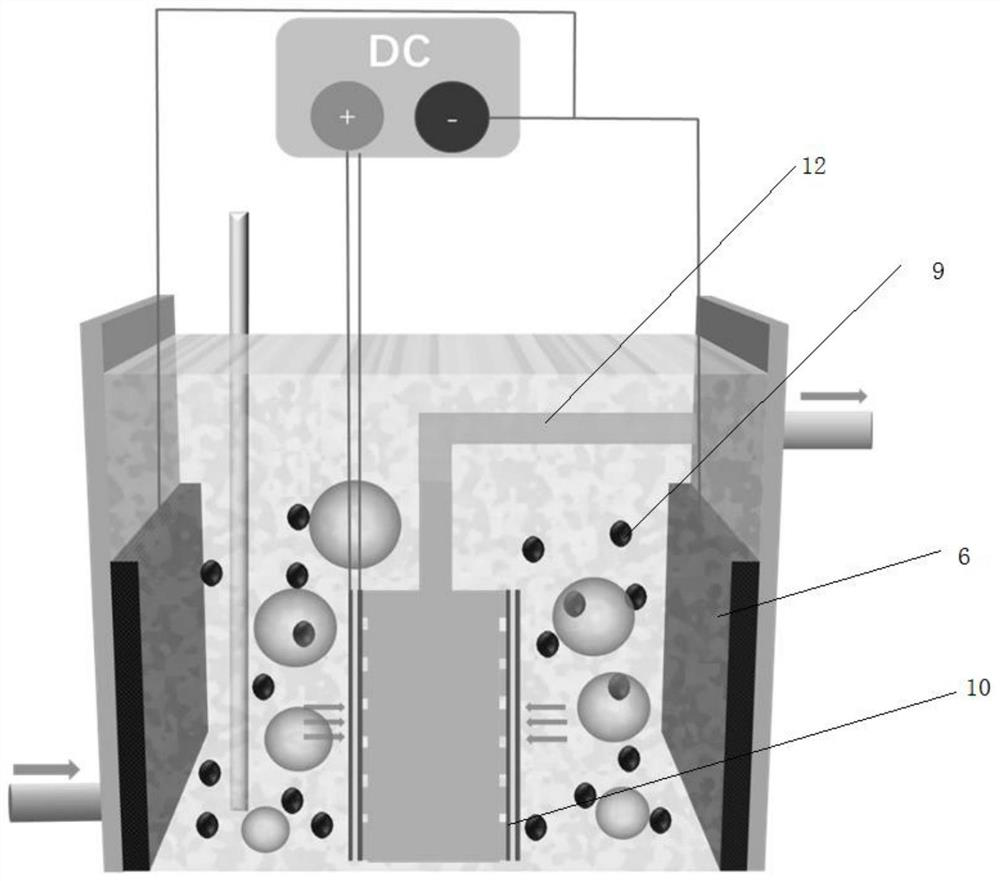

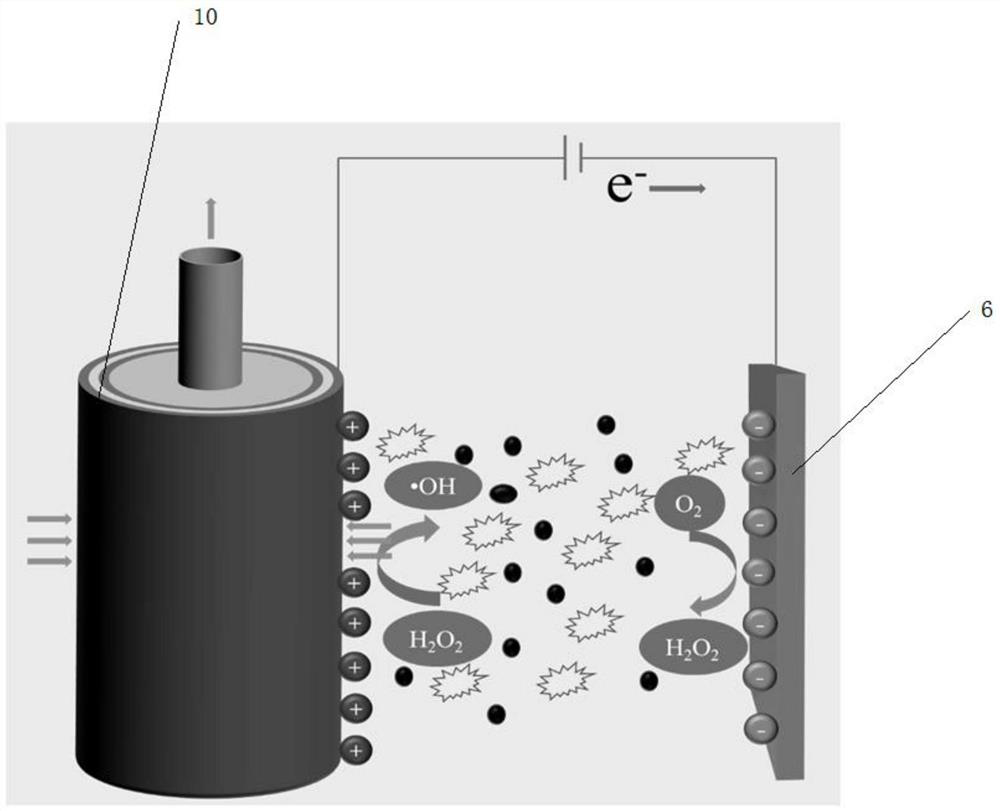

[0051] Microcurrent-like Fenton fluidized bed membrane reactor for treating refractory wastewater, the structure is as follows Figure 1-3 As shown, the reactor body 5 is included, the bottom and the top of the reactor body 5 are respectively provided with a water inlet and a water outlet, the interior of the reactor body is provided with a membrane reaction separation device, and the membrane reaction separation device includes a membrane electrode 10 and a counter electrode 6 , the membrane electrode 10 is located between the two pairs of electrodes 6, the membrane electrode 10 includes a double-layer membrane, the double-layer membrane is wrapped on a porous support tube, the bottom end of the porous support tube is closed, and the middle of the top is connected with a discharge hose 12 ( figure 1 not shown in figure 2 shown), the discharge hose 12 is connected with the water outlet of the reactor body, the water outlet is connected with the water outlet pipe, the side wal...

Embodiment 2

[0056] With the micro-current class Fenton fluidized bed membrane reactor for the treatment of refractory wastewater described in Example 1, the difference is:

[0057] The distance between the membrane electrode 10 and the counter electrode 6 was 4.5 cm.

Embodiment 3

[0059] With the micro-current class Fenton fluidized bed membrane reactor for the treatment of refractory wastewater described in Example 1, the difference is:

[0060] The distance between the membrane electrode 10 and the counter electrode 6 was 2.5 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com