Composite protective agent for freeze-drying lactobacillus bulgaricus

A technology of lactobacillus and protective agent, applied in the direction of bacteria, preserved microorganisms, microorganisms, etc., can solve the problems of large loss of living cells, failure to maintain physiological and biochemical characteristics and biological activity, achieve high survival rate, maintain physiological and biochemical Properties and biological activity, tolerance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

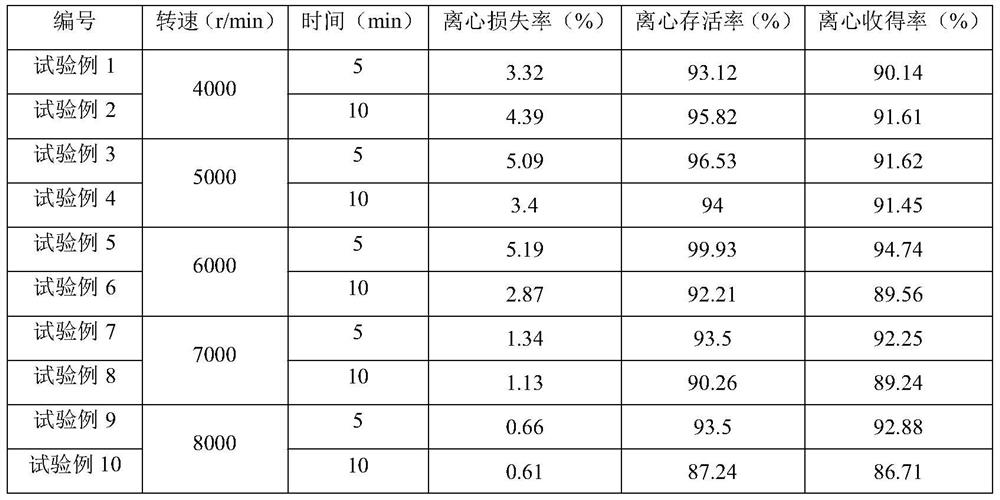

[0027] Embodiment 1: the influence of different centrifugation speed and centrifugation time on Lactobacillus bulgaricus

[0028] In order to use the composite protective agent for freeze-drying in the freeze-drying of Lactobacillus bulgaricus, it is necessary to prepare Lactobacillus bulgaricus strain first. Refer to the following steps to prepare Lactobacillus bulgaricus bacteria slurry, set up test examples, compare the effects of different centrifugal speed and centrifugation time on the centrifugal loss rate and centrifugal survival rate of Lactobacillus bulgaricus, and determine the optimal centrifugal process. The specific centrifugal process parameters and results are shown in Table 1.

[0029] The specific steps of the test example are:

[0030] 1) Activation and culture: Lactobacillus bulgaricus was streaked in MRS plate medium, and cultured in a constant temperature and airtight manner at 37°C (10-18h). Activated for 3 times in a row, after microscopic examination...

Embodiment 2

[0040] Embodiment 2: prepare the composite protective agent for Lactobacillus bulgaricus freeze-drying of different proportions

[0041] Dissolve cysteine hydrochloride and bovine serum albumin in part of sterile water, filter and sterilize with 0.22μm PES sterile filter membrane to obtain solution A; dissolve gum arabic, stachyose and inulin in the remaining water , sterilized at 115° C. for 20 min to obtain solution B; after mixing solution A and solution B evenly, a composite protective agent for freeze-drying of Lactobacillus bulgaricus was obtained, which was stored at 4° C. for later use.

[0042] Among them, the amounts of gum arabic, stachyose, cysteine hydrochloride, inulin and bovine serum albumin are shown in Table 2.

[0043] Table 2 prepares the mass percent of each component of Lactobacillus bulgaricus lyophilized composite protective agent

[0044] Sample serial number gum arabic stachyose Cysteine hydrochloride Inulin bovine serum albu...

Embodiment 3

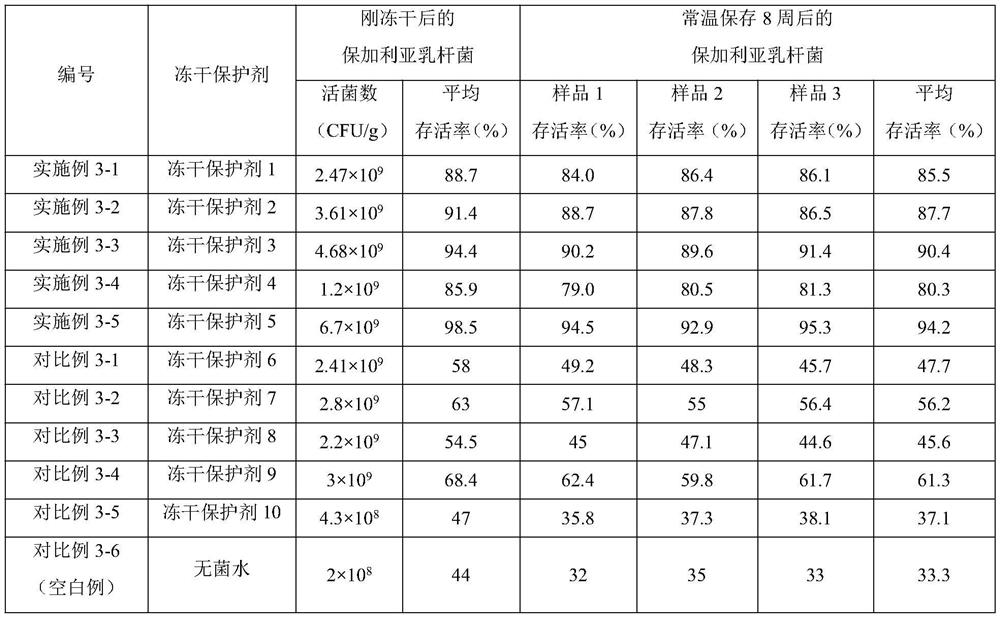

[0045] Embodiment 3: the freeze-drying effect comparison of the Lactobacillus bulgaricus freeze-drying composite protective agent of different proportions

[0046] Prepare Lactobacillus bulgaricus freeze-dried bacteria powder with reference to the following steps, set blank example and test example, compare without adding freeze-drying protection agent (blank example), add the different freeze-drying protection agent (test example) prepared in Example 2 to bulgaric milk. Bacillus lyophilization effect.

[0047] The preparation steps of the blank example are:

[0048] (1) Activation and culture: Lactobacillus bulgaricus was streaked in MRS plate medium, and cultured at 37°C in a constant temperature and airtight manner (10-18h). Activated for 3 times in a row, after microscopic examination, there were no bacteria and no abnormality in shape, then the inoculum of 2% (v / v) was inserted into the MRS liquid medium, and incubated at a constant temperature of 37 °C for 18 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com