Common direct current bus permanent magnet synchronous spinning machine control system

A common DC bus, permanent magnet synchronization technology, applied in the control system, motor control, control of multiple DC motors, etc., can solve the problems of exchange efficiency, energy exchange, etc., to improve the control effect, mechanical energy and electrical energy conversion transmission The effect of balance improvement, process smoothing of motor voltage increase or decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below.

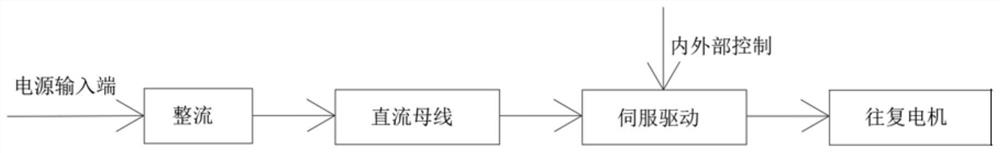

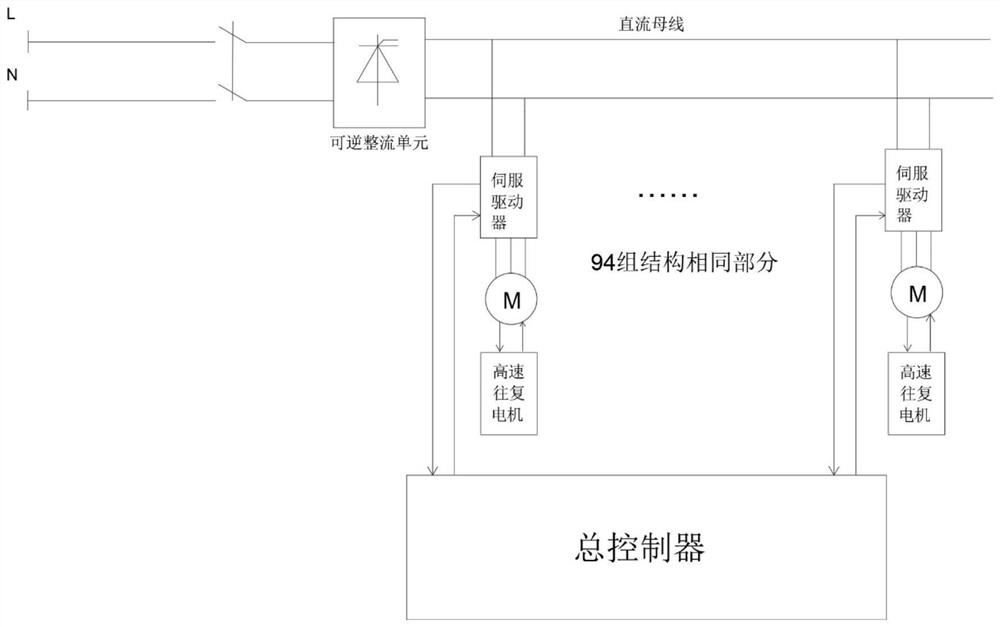

[0019] like figure 1 As shown, the common DC bus permanent magnet synchronous spinning machine control system of the present invention includes a reversible rectifier unit, a DC bus, a servo driver, a high-speed reciprocating motor and a general controller. The power input end is powered by two DC busbars drawn from the reversible rectifier unit. One end of the 96 servo drives is connected to the DC busbar, the other end is connected to the high-speed reciprocating motor, and the main controller is also connected to the servo drive.

[0020] The reversible rectifier unit can convert the AC voltage into a stable DC voltage, and its power part is composed of two anti-parallel thyristor bridges, which can feed back the energy generated by the motor braking to the power grid, and can also work in the reverse state, That is, the energy on the grid is supplie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com