Electrostatic spraying method for preparing copper substrate super-hydrophobic surface

A superhydrophobic surface, electrostatic spraying technology, applied in special surfaces, pretreatment surfaces, devices for coating liquids on surfaces, etc., can solve the problems of restricting development, poor mechanical durability and chemical stability of superhydrophobic materials, etc. The effect of preparation cost, easy mass production, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

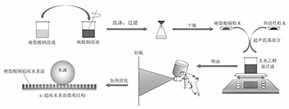

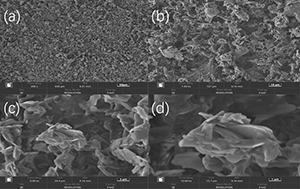

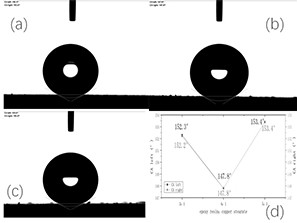

[0025] The present invention utilizes an electrostatic spraying machine to provide a superhydrophobic surface of copper substrate prepared by an electrostatic spraying method. The present invention will be described in detail below with reference to the accompanying drawings:

[0026] A preparation method of a copper substrate superhydrophobic surface structure designed by the present invention, the main steps of the method include:

[0027] The technical problem to be solved by the present invention is to provide a method for preparing a superhydrophobic surface of a copper substrate by using an electrostatic spraying method to enhance heat transfer. Using this method, a copper substrate with a superhydrophobic surface structure can be prepared simply and quickly, and the prepared The superhydrophobic surface has good stability, low preparation cost, and easy large-scale production.

[0028] In order to solve the above-mentioned technical problems, the preparation method of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com