Porous granular ammonium nitrate fuel oil explosive with stable and safe performance

A technology for ammonium explosives and granular ammonium nitrate, which is applied to explosives and other directions, can solve the problems of low flash points of nitropropane and dinitrophenol, the performance of porous granular ammonium explosives is reduced, and the occupational health of workers is affected, and the detonation can be achieved. The effect of improving sensitivity, ensuring occupational health, and having no irritating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

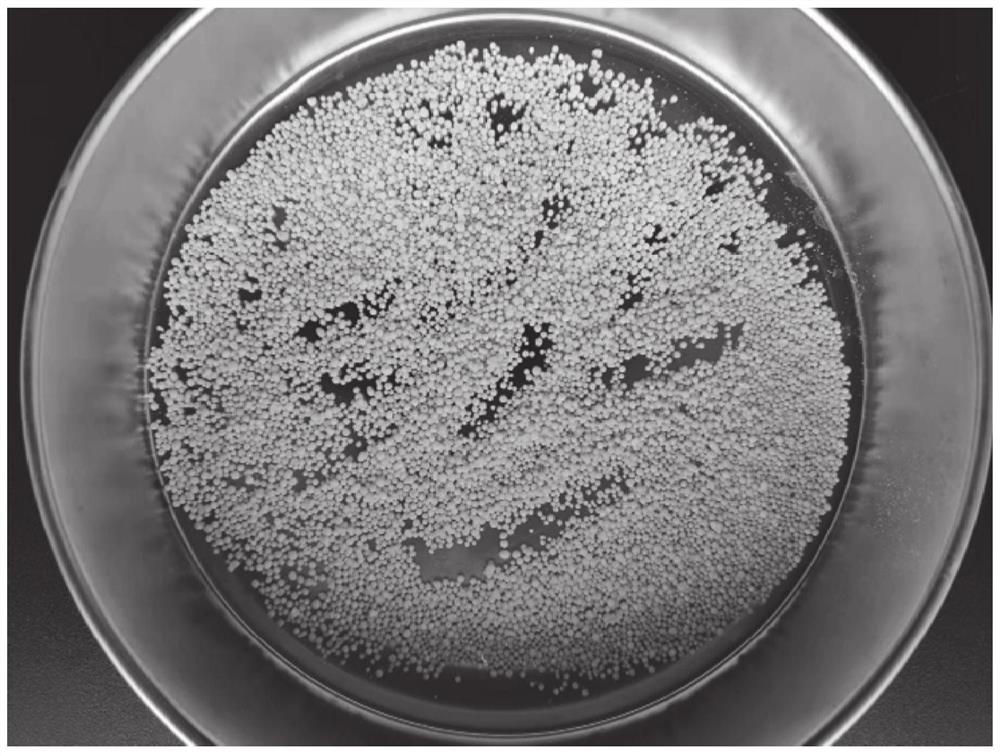

Image

Examples

Embodiment 1

[0039] This embodiment provides a stable and safe porous granular ammonium explosive, including 940 g of porous granular ammonium nitrate, 60 g of liquid paraffin, and the liquid paraffin is F-T synthetic liquid paraffin 1# produced by Inner Mongolia Yitai Coal to Oil Co., Ltd.

[0040] The preparation method is as follows: adding technical grade liquid paraffin to porous granular ammonium nitrate at room temperature, and stirring for 2 minutes.

Embodiment 2

[0042] This embodiment provides a conventional porous granular ammonium explosive, including 940 g of porous granular ammonium nitrate and 60 g of 0# diesel oil.

[0043] The preparation method is as follows: adding 0# diesel oil to the porous granular ammonium nitrate at room temperature and stirring for 2 minutes.

Embodiment 3

[0045] This embodiment is prepared according to the method in CN105111033A, 850 g of porous granular ammonium nitrate, 70 g of aliphatic nitropropane, 50 g of epoxy resin, and 10 g of bamboo charcoal powder.

[0046] The explosive preparation method of this embodiment is as follows: adding aliphatic compound nitropropane to porous granular ammonium nitrate, mixing and stirring at 90° C. for 25s, then adding epoxy resin and bamboo charcoal powder, and stirring evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com