Method for preparing alkyl naphthalene lubricant base oil from coal alpha-olefin

A technology of alkylnaphthalene lubricating oil and base oil, which is applied in the direction of lubricating compositions, base materials, petroleum industry, etc., can solve the problems of complex reaction process, easy deactivation of catalyst, and non-environmental protection of catalyst, and achieve remarkable economic benefits and avoid Use of high-pressure equipment to achieve clean and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

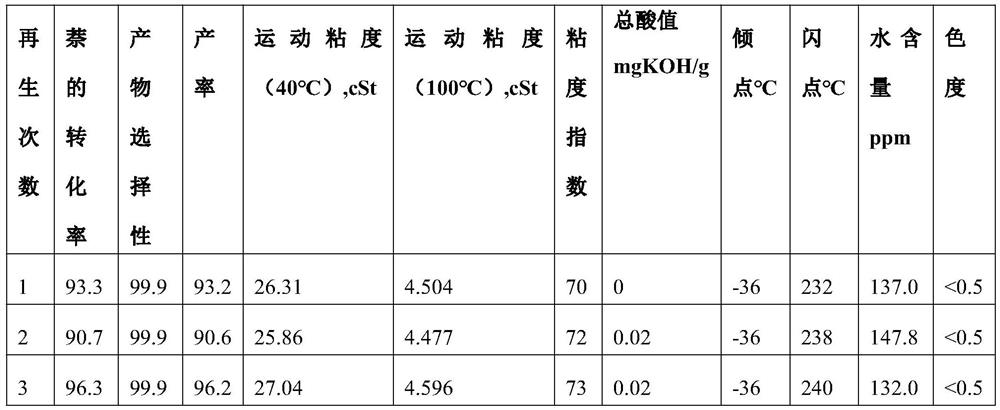

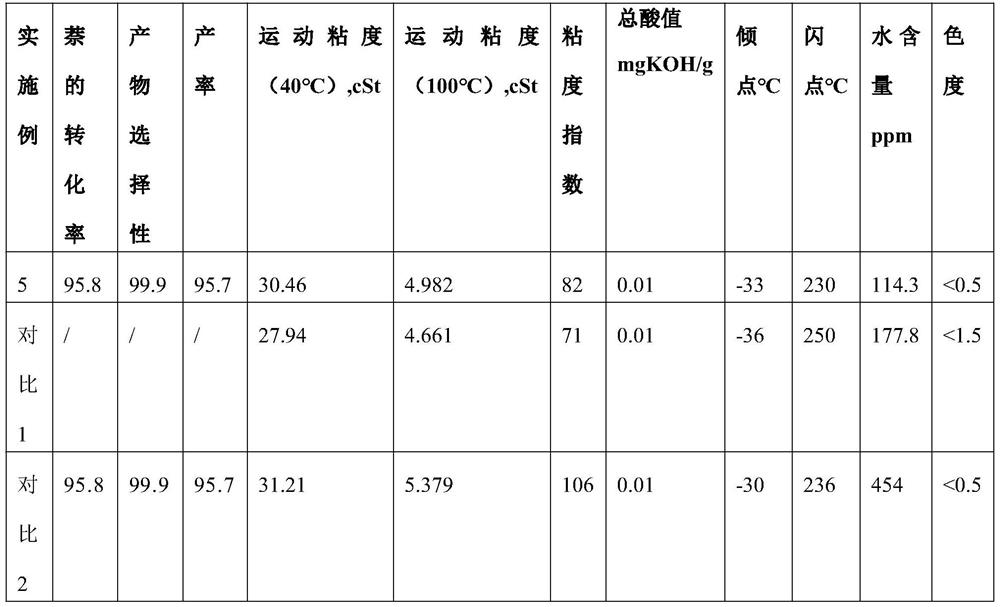

Examples

Embodiment 1

[0025] First, 154g of C16α-olefin, 80g of naphthalene and 140g of n-decane were mixed and stirred, 16g of Y zeolite was added, and the reaction was carried out at 165°C for 8h. The product is filtered and distilled to obtain alkylnaphthalene. In the reaction, the conversion rate of naphthalene was 87.5%, the product selectivity was 99.9%, and the product yield was 87.4%. The addition of the solvent n-decane can avoid the difficulty of stirring caused by the too high viscosity of the reaction system, and make the mixing more sufficient and the reaction more sufficient.

[0026] The color of the alkylnaphthalene product obtained in this example is light yellow, the viscosity at 40°C is 23.93cSt, the viscosity at 100°C is 4.285cSt, the viscosity index is 71, the pour point is -36°C, the flash point is 232°C, and the chromaticity is <0.5 , the acid value is 0.01mgKOH / g, and the water content is 185.3ppm.

Embodiment 2

[0028] First, 168g C16α-olefin, 80g naphthalene and 149g n-decane were mixed and stirred, 28g Y zeolite was added, and the reaction was carried out at 165°C for 8h. The product is filtered and distilled to obtain alkylnaphthalene. In the reaction, the conversion rate of naphthalene was 87.1%, the product selectivity was 99.9%, and the product yield was 87.0%.

[0029] The color of the alkylnaphthalene product obtained in this example is light yellow, the viscosity at 40°C is 28.21cSt, the viscosity at 100°C is 4.578cSt, the viscosity index is 57, the pour point is -36°C, the flash point is 238°C, and the chromaticity is <0.5 , the acid value is 0.01mgKOH / g, and the water content is 190.1ppm.

Embodiment 3

[0031] First, 154g of C16α-olefin, 80g of naphthalene and 94g of n-decane were mixed and stirred, 16g of Y zeolite was added, and the reaction was carried out at 165°C for 8h. The product is filtered and distilled to obtain alkylnaphthalene. In the reaction, the conversion rate of naphthalene was 87.5%, the product selectivity was 99.9%, and the product yield was 87.4%.

[0032] The color of the alkylnaphthalene product obtained in this example is light yellow, the viscosity at 40°C is 25.59cSt, the viscosity at 100°C is 4.444cSt, the viscosity index is 71, the pour point is -36°C, the flash point is 236°C, and the chromaticity is <0.5 , the acid value is 0.01mgKOH / g, and the water content is 188.7ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com