Solid acid catalyst based on MCM-41 mesoporous molecular sieve as well as preparation method and application of solid acid catalyst

A technology of MCM-41 and solid acid catalyst, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex production process, lack of types, poor stability, etc., and achieve low raw materials and short synthesis cycle The effect of short, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Solid acid catalyst S(1) based on MCM-41 mesoporous molecular sieve

[0029] (1) The preparation method is as follows

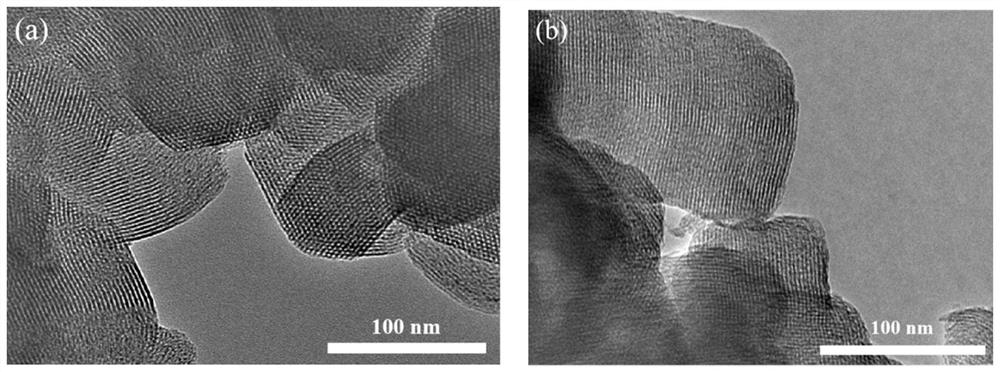

[0030] 1. Preparation of MCM-41 mesoporous molecular sieve

[0031] Dissolve 7.289 g of CTAB in 40 mL of distilled water and stir vigorously until a clear solution is formed. Dissolve 28.42 g of sodium silicate nonahydrate in 40 mL of distilled water until the sodium silicate is completely dissolved. Then, the CTAB solution was slowly added to the aqueous sodium silicate solution, and after stirring was continued for 30 min in a water bath at 35°C, the reaction solution was adjusted to pH=11 with a mixed solution of concentrated sulfuric acid and distilled water with a volume ratio of 1:1, and stirring was continued for 3 h. The reaction mixture was transferred to an autoclave, hydrothermally reacted at 120 °C for 24 h, filtered, washed and dried. Finally, the obtained solid was calcined at 550 °C for 6 h to obtain MCM-41 mesoporous molecula...

Embodiment 2

[0038] Example 2 Solid acid catalyst S (2) based on MCM-41 mesoporous molecular sieve

[0039] The method is the same as in Example 1. Just step 2, with 0.0148g AlCl 3 Instead of 0.1038g AlCl in Example 1 3 , to obtain Al-MCM-41 solid acid catalyst whose Al atomic mass is 1% by mass of MCM-41 mesoporous molecular sieve, named as 1wt% Al-MCM-41 catalyst, and marked as catalyst S(2).

Embodiment 3

[0040] Example 3 Solid acid catalyst S (3) based on MCM-41 mesoporous molecular sieve

[0041] The method is the same as in Example 1. Just step 2, with 0.0445g AlCl 3 Instead of 0.1038g AlCl in Example 1 3 , to obtain an Al-MCM-41 solid acid catalyst whose Al atomic mass is 3% of the mass of MCM-41 mesoporous molecular sieve, which is named as 3wt% Al-MCM-41 catalyst and marked as catalyst S(3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com