Continuous machining assembly line based on mechanical arm

An assembly line and manipulator technology, which is applied to the device for coating liquid on the surface, coating, surface pretreatment, etc., can solve the problems of affecting production efficiency, reducing plate spraying and drying processes, increasing working hours, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

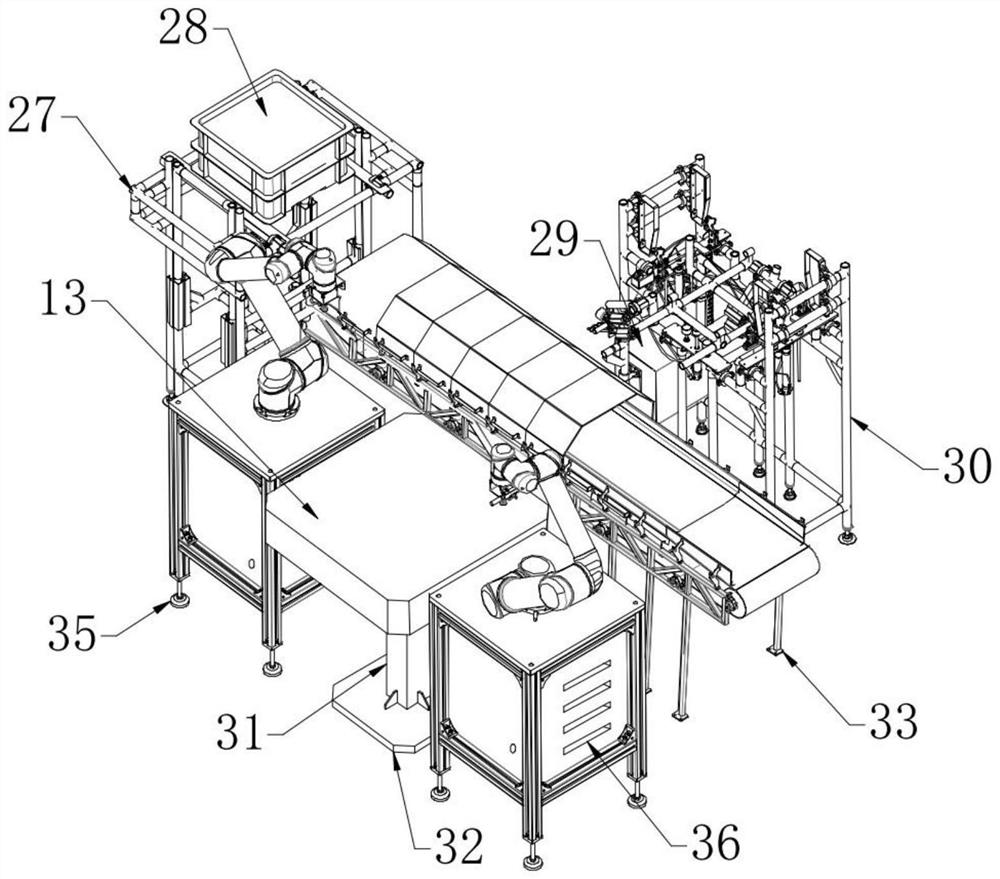

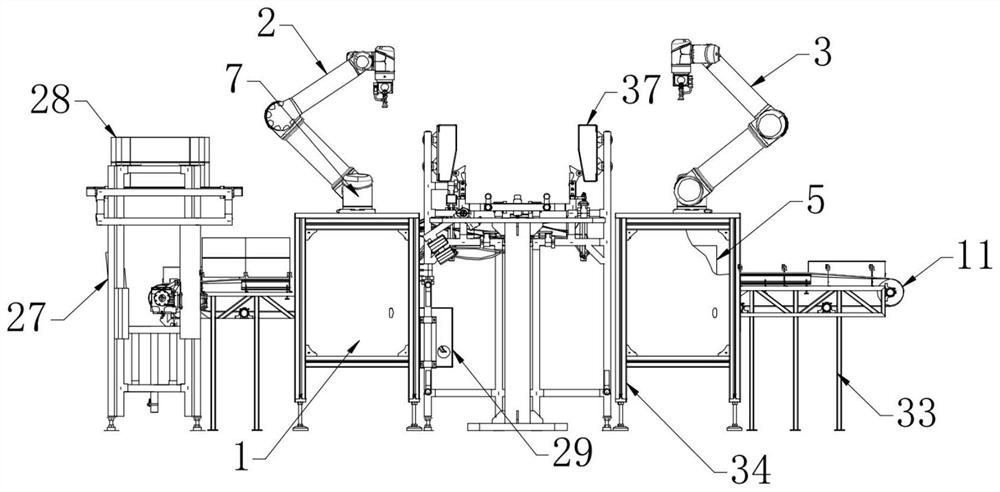

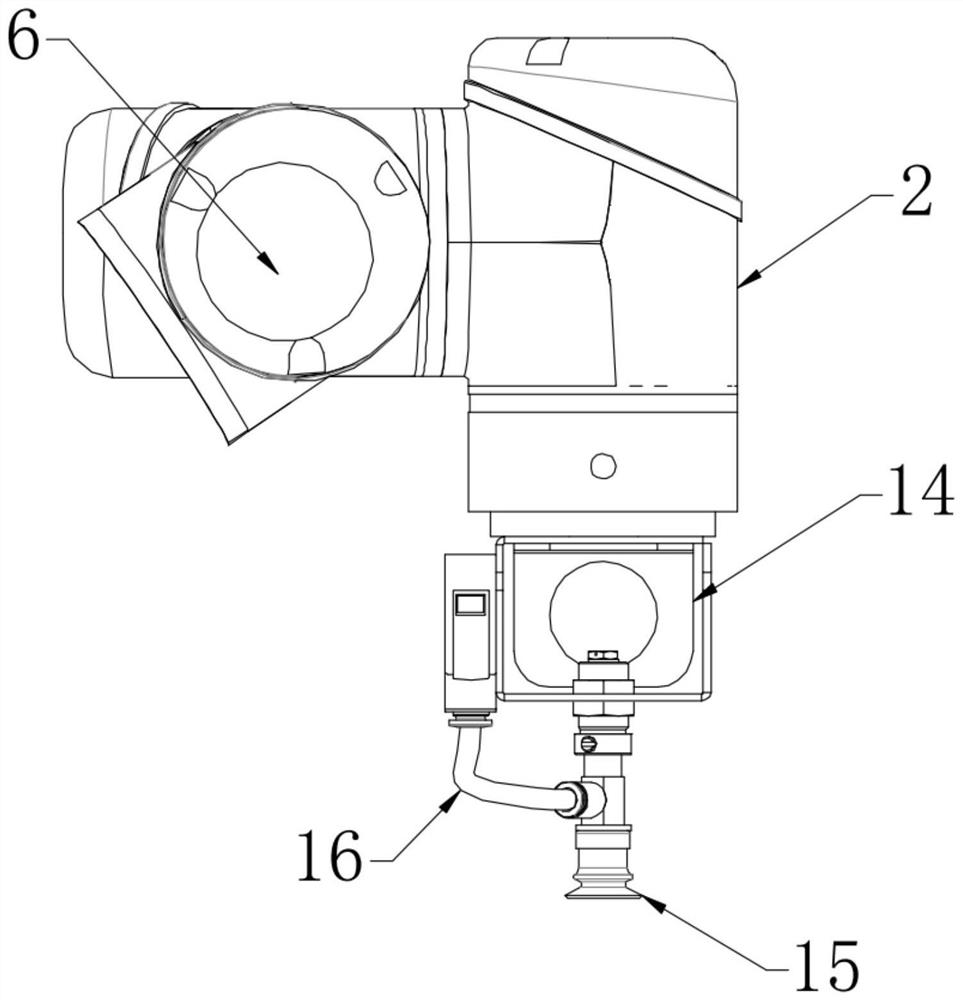

[0032] For this example, see Figure 1-8 , which specifically implements a continuous processing line based on a manipulator, including a main control box 1, a reclaiming robot arm 2, a feeding robot arm 3 and a conveyor belt 4, and the inside of the main control box 1 is provided with an auxiliary reclaiming machine. The controller 5 for the operation of the arm 2 and the feeding robotic arm 3, the reclaiming robotic arm 2 and the feeding robotic arm 3 are both located on the surface of the main control box 1, and the reclaiming robotic arm 2 and the feeding robotic arm 3 are equipped with a The movable joint 6 and the rotating shaft 7, one end of the rotating shaft 7 is electrically connected with the controller 5, and the other end of the rotating shaft 7 is respectively connected with the reclaiming mechanical arm 2 and the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com