Preparation method of acetylated modified high-amylose corn starch

A corn starch, high straight chain technology, applied in the field of food processing, can solve the problems of low efficiency, complexity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 A kind of preparation method of acetylation modified high amylose corn starch

[0050] (1) Disperse high amylose corn starch in 2.5mol / L sodium sulfate solution, stir at a speed of 250r / min at a temperature of 35~45°C, and make a starch emulsion with a mass fraction of 10%;

[0051] (2) 50% sodium hydroxide solution is added dropwise for activation, wherein the mass ratio of NaOH and high amylose corn starch dry base is 0.2~0.4:1, after 30min of reaction, adjust pH with concentration of 2.5mol / L hydrochloric acid is neutral, so that the activation is terminated, and the activated high amylose corn starch is obtained;

[0052] (3) heating and stirring the activated high amylose corn starch emulsion in a water bath, adjusting pH to 7-12 with NaOH solution, dripping vinyl acetate in the high amylose corn starch emulsion to carry out acetylation reaction, and the temperature of the water bath is controlled at 35-55 ℃, React for 1-5h, and then adjust the pH of ...

Embodiment 2

[0055] Example 2 Determination of the preparation process parameters of acetylated modified high amylose corn starch

[0056] 1. One-factor experiment

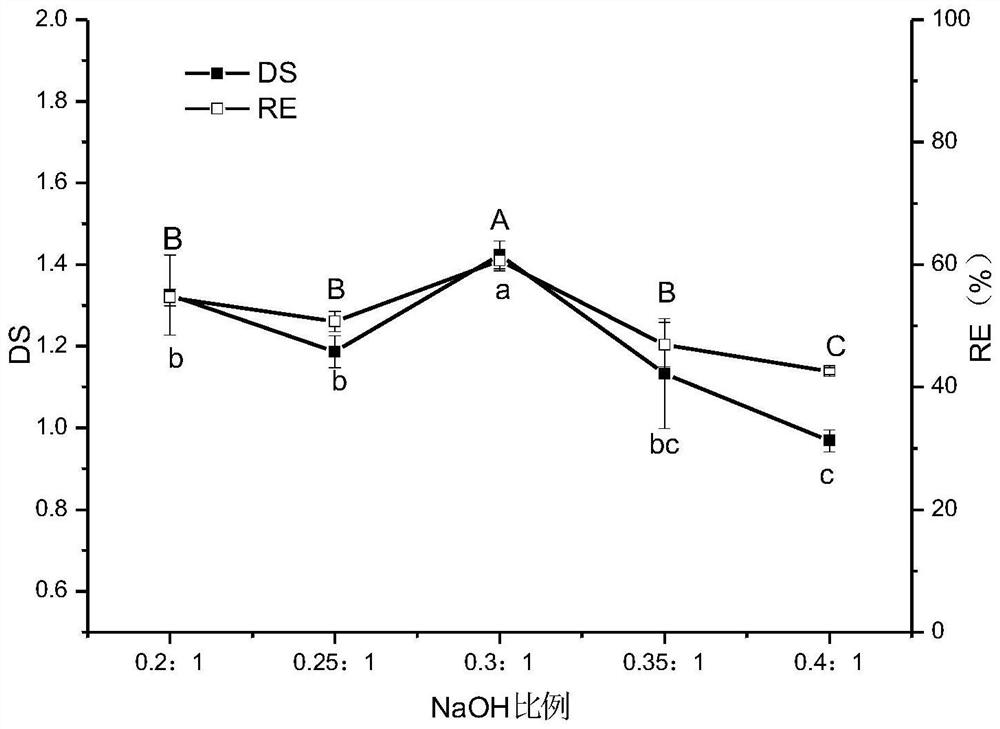

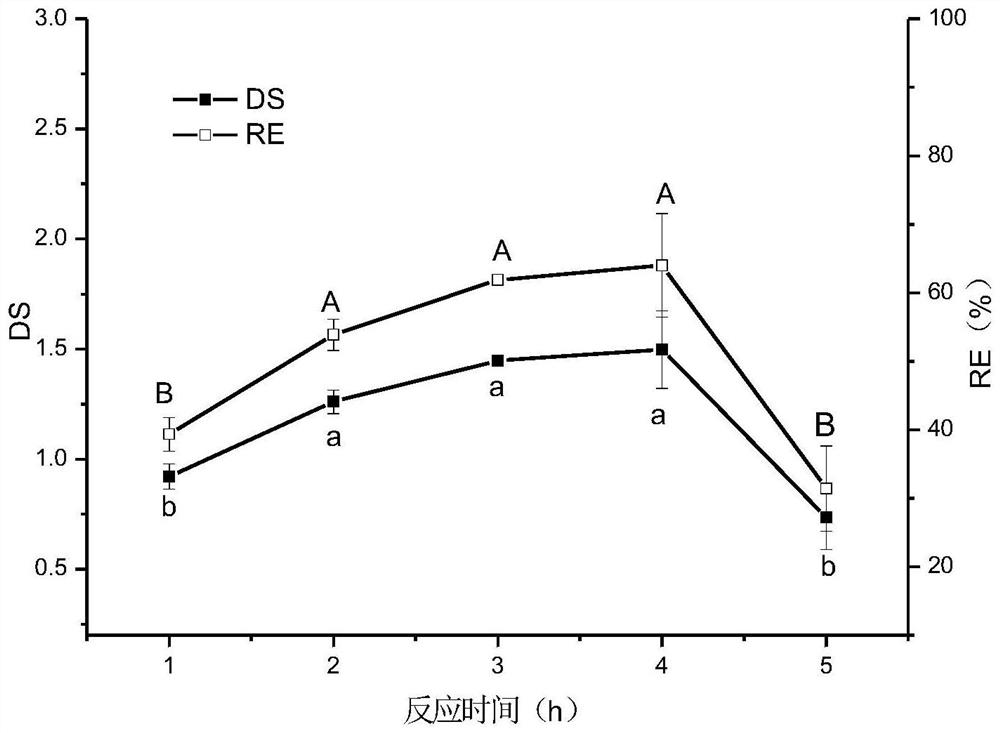

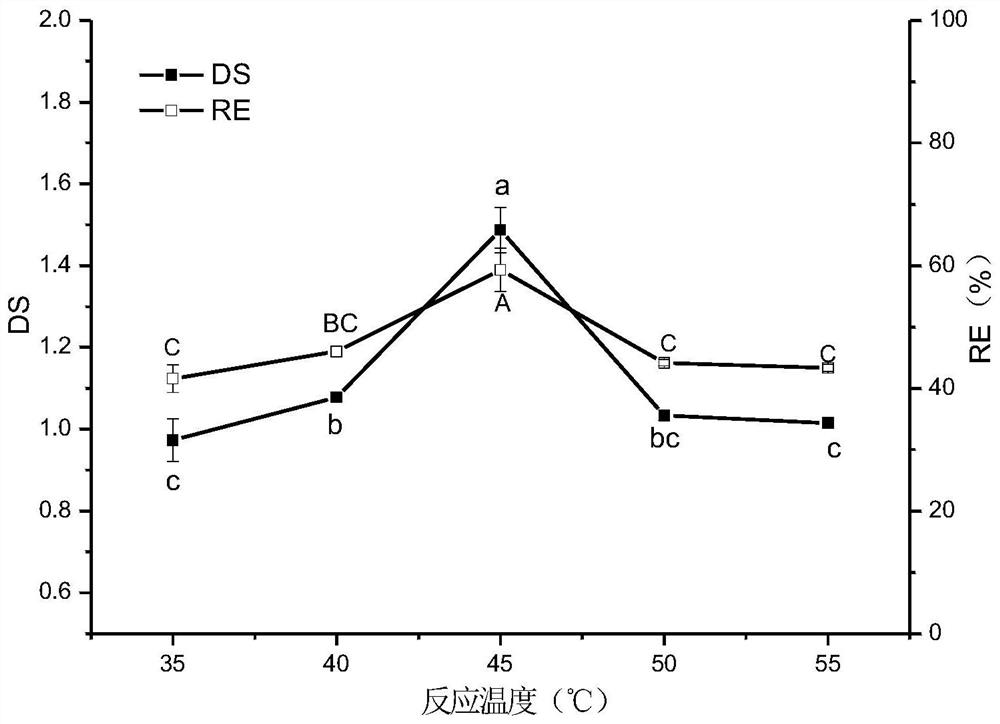

[0057] Select the mass ratio of NaOH mass and high amylose corn starch dry basis during activation (0.2~0.4:1), acetylation reaction temperature (35~55℃), acetylation reaction time (1~5h), acetylation reaction pH value (8 to 12) and the mass ratio of vinyl acetate to dry starch (0.01 to 6.25:1) were single factors, and the degree of substitution and reaction efficiency were used as optimization indicators to single-factor the preparation of acetylated high amylose corn starch. experiment. The level of one factor was changed, and the levels of the other factors were fixed, and the effects of a single factor on the degree of substitution (DS) and reaction efficiency (RE) of the esterification reaction were studied. The result is as Figure 1-5 shown.

[0058] (1) Determination of the degree of substitution:

[0059] Take 1....

Embodiment 3

[0069] Embodiment 3 A kind of preparation method of acetylation modified high amylose corn starch

[0070] (1) Disperse high amylose corn starch in 2.5mol / L sodium sulfate solution, stir at a speed of 250r / min at a temperature of 42.5°C, to prepare a starch emulsion with a mass fraction of 10%;

[0071] (2) 50% sodium hydroxide solution is added dropwise to the starch emulsion for activation, wherein the mass ratio of NaOH and high amylose corn starch dry base is 0.3:1, after 30min of reaction, the concentration is 2.5mol / L hydrochloric acid Adjust the pH to be neutral, so that the activation is terminated, and the activated high amylose corn starch is obtained;

[0072] (3) Heating and stirring the activated high amylose corn starch emulsion in a water bath, adjusting the pH to 10 with NaOH solution, adding vinyl acetate dropwise to the high amylose corn starch emulsion for acetylation reaction, controlling the temperature of the water bath at 42.5 ° C, and reacting for 3.5 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com