Magnetic nanofiber aerogel for heavy oil separation

A magnetic nano and nano fiber technology, applied in separation methods, liquid separation, other chemical processes, etc., can solve the problems of affecting the magnetic properties of aerogels, uneven hydrophobic modifiers, and easy falling of magnetic nanoparticles, and achieve magnetic The effect of uniform particle distribution, reduced addition amount, and uniform hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

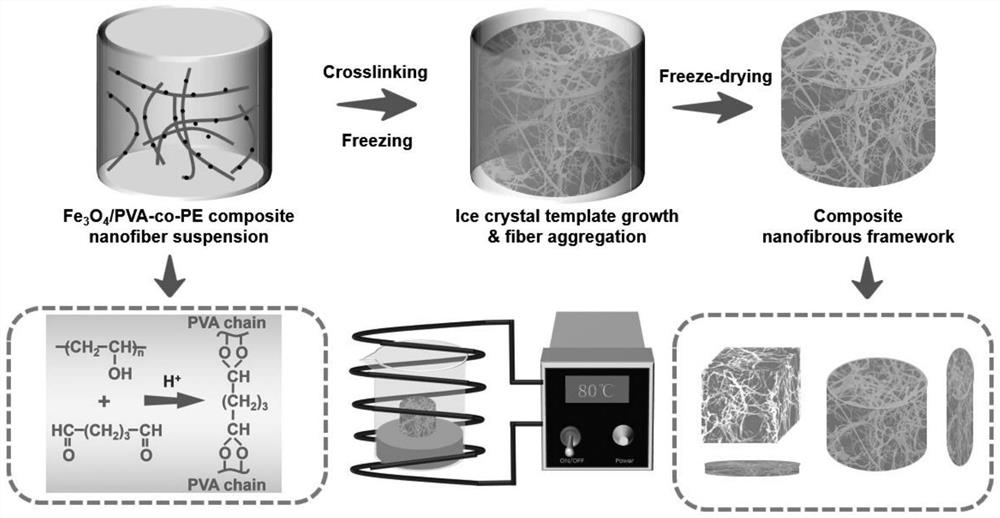

[0041] S1, 5g ferric oxide and 95g PVA-co-PE nanofibers are melt-blended to obtain magnetic nanofibers, wherein the mass percentage of the addition of magnetic particles and the mass sum of magnetic particles and nanofibers is 5%;

[0042] S2, under the condition of magnetic stirring, configure the magnetic nanofibers prepared in step S1 into a magnetic nanofiber suspension, take 5g of the magnetic nanofiber suspension and mix it with 0.5g of glutaraldehyde to obtain a mixture, and then pour the above mixture into Put it into the mold, then use liquid nitrogen to pre-freeze the mold, and then put the pre-frozen mold into the pre-cooled freeze dryer, and freeze-dry it for 48 hours to obtain PVA-co-PE doped with iron tetroxide. Nanofiber aerogel, wherein, the magnetic nanofiber suspension is obtained by dispersing magnetic nanofibers in water and isopropanol, and the mass ratio of magnetic nanofibers, water and isopropanol is 3:5:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com