A special resin liquid for hydrophobic melamine foam, preparation method and foaming liquid prepared therefrom

A technology of hydrophobic melamine and melamine, which is applied in the field of melamine foam plastics, can solve the problems of high production cost, complex process, and degradation of hydrophobic performance, and achieve the effects of easy industrial production, simple and convenient operation, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of special resin solution

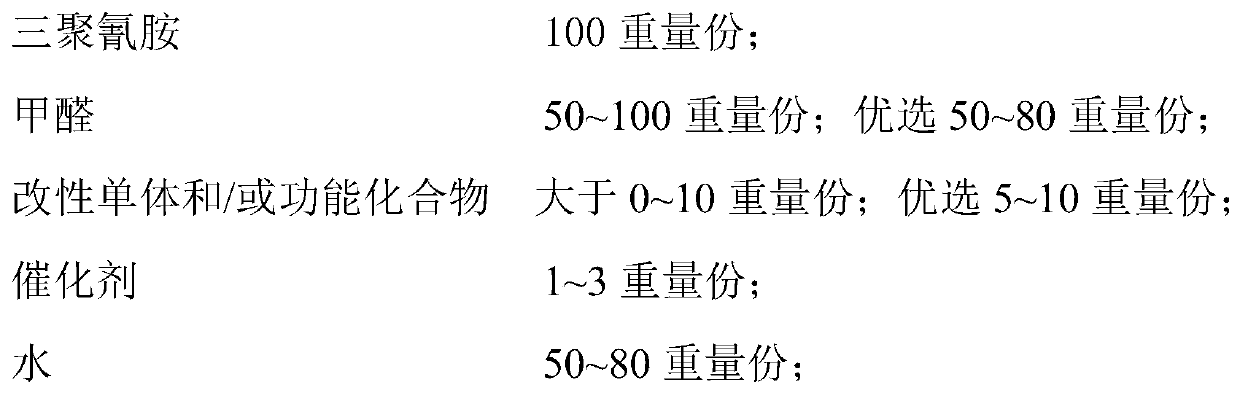

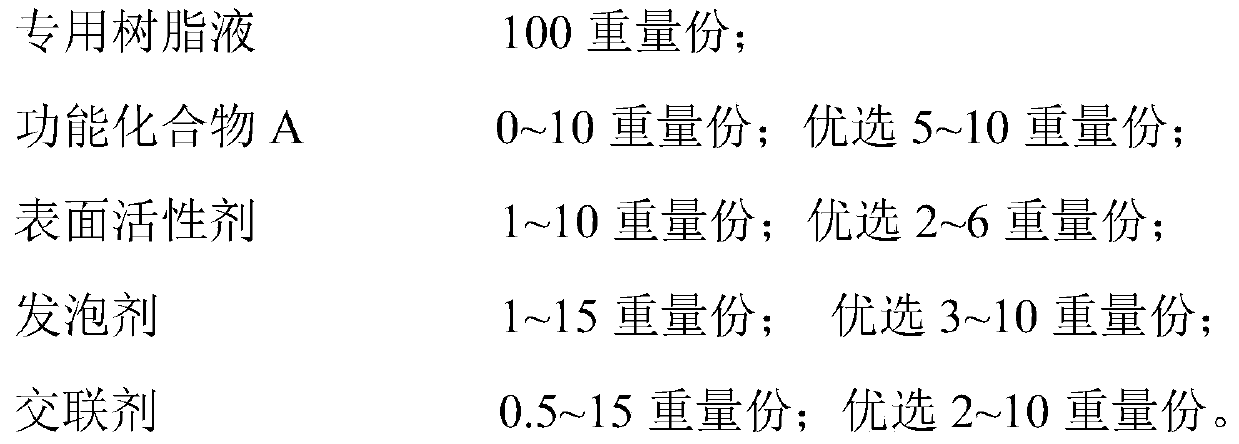

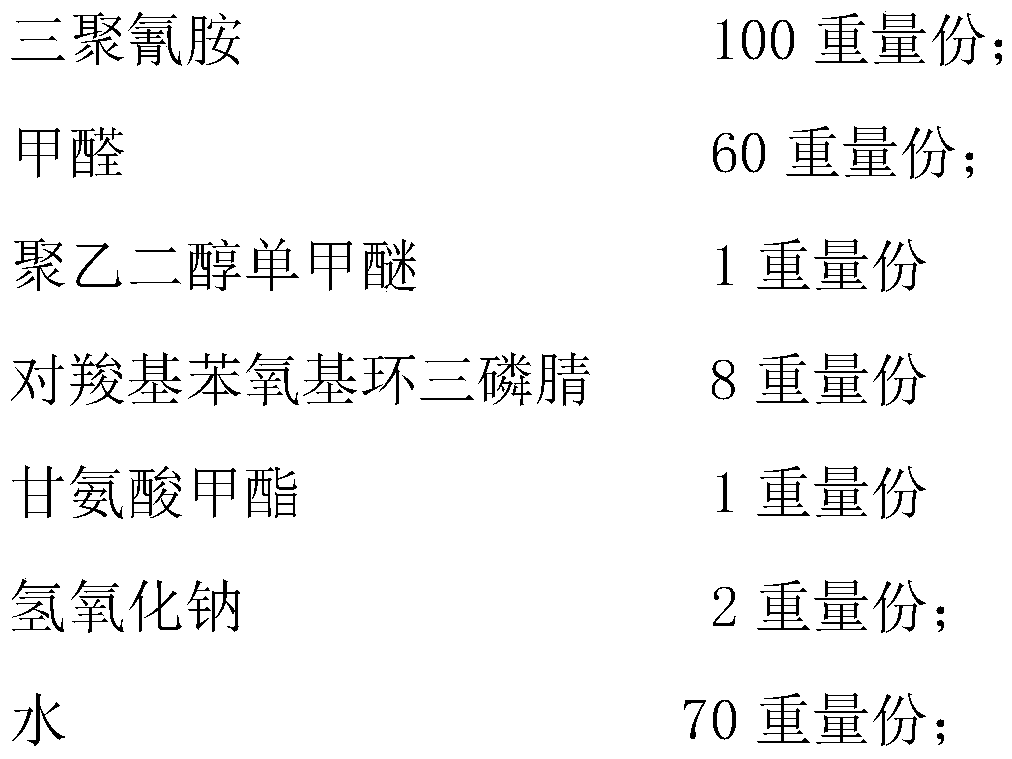

[0051] Raw material ratio:

[0052]

[0053] Add polyethylene glycol monomethyl ether, hexa-p-carboxyphenoxy cyclotriphosphazene, and glycine methyl ester into the reactor, and react at 60 to 70 °C for 40 minutes; then add other raw materials, and then react at 980 °C for 50 to 80 minutes to obtain Special resin liquid.

Embodiment 2

[0055] Preparation of special resin solution

[0056] Raw material ratio:

[0057]

[0058] The melamine, formaldehyde, sodium hydroxide, and water were reacted at 98° C. for 40 minutes, and polyaryloxyphosphazene and ammonium polyphosphate were added to continue the reaction for 40 minutes to obtain a special resin solution.

Embodiment 3

[0060] Preparation of special resin solution

[0061] Raw material ratio:

[0062]

[0063] The above-mentioned raw materials were reacted at 98° C. for 100 min to obtain a special resin solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com