A core-shell type surface sizing enhancer and preparation method thereof

A surface sizing and strengthening agent technology, applied in the direction of water repellent addition, papermaking, coating, etc., can solve the problems of insufficient crosslinking network, low solid content of emulsion, and easy separation of chemical crosslinking, so as to improve film formation performance, improvement of surface strength, and improvement of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of a core-shell type surface sizing enhancer of the present invention comprises the following steps:

[0037] 1) mix the alkyd resin and diglyme in a mass ratio of 1:0.3-1 to obtain the alkyd resin diglyme solution;

[0038] 2) Heat up the alkyd resin diethylene glycol dimethyl ether solution (including 100 parts of alkyd resin) to 50-75° C., add 15-30 parts of isocyanate monomer, and react for 1-2 hours. Then add 1-3 parts of hydroxyl-containing vinyl monomers into the reaction solution, and continue the reaction for 1 hour to obtain component A.

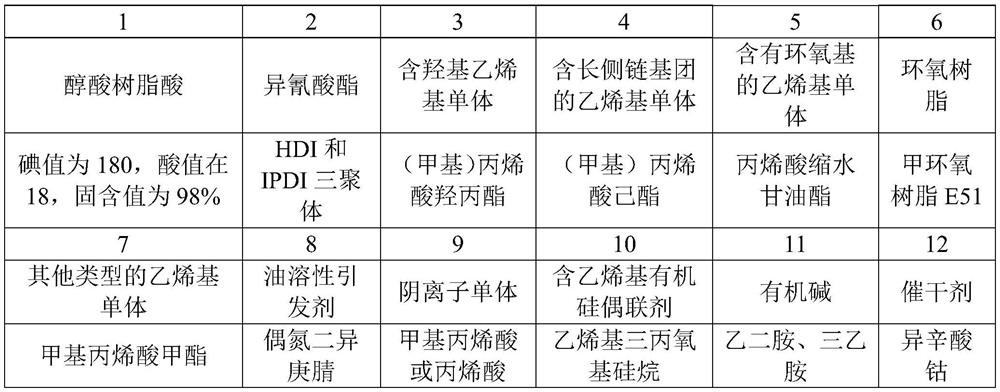

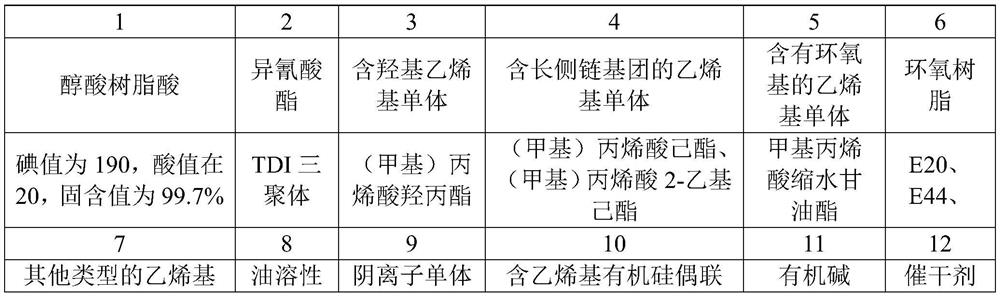

[0039] 3) Mix 1-5 parts of vinyl monomers containing long side chain groups, 3-5 parts of vinyl monomers containing hydroxyl groups, 0.5-2 parts of vinyl monomers containing epoxy groups, 1-3 parts of ring Oxygen resin, 10-20 parts of other types of vinyl monomers and 1-3 parts of oil-soluble initiator are mixed to obtain mixed liquid B.

[0040] 4) Mix 1 / 2 of component A, 2-10 parts of anionic monomer...

Embodiment 1

[0058] 1) Mix alkyd resin (oleic acid iodine value 155, acid value 18, mass fraction 98%) and diglyme in a mass ratio of 1:0.5 to obtain alkyd resin diglyme solution;

[0059] 2) The alkyd resin diethylene glycol dimethyl ether solution (including 100 parts of alkyd resin) was heated to 60° C., 17.5 parts of MDI trimer was added, and reacted for 1 hour. Then, 1.5 parts of hydroxyethyl methacrylate was added into the reaction liquid, and the reaction was continued for 1 hour to obtain component A.

[0060] 3) 2 parts of vinyl monomer of isooctyl methacrylate, 3 parts of hydroxypropyl methacrylate, 1 part of glycidyl acrylate, 1.5 parts of epoxy resin E44, 12 parts of styrene and 2 parts of benzene peroxide Formyl is mixed to obtain a mixed liquid B.

[0061] 4) Mix 1 / 2 of component A, 4 parts of acrylic acid, 2 parts of isooctyl methacrylate, 2 parts of hydroxypropyl methacrylate, 1.5 parts of glycidyl acrylate, 2 parts of epoxy resin E44, 1.2 parts of ethylene Tripropoxysil...

Embodiment 2

[0066] 1) Mix alkyd resin (oleic acid iodine value 180, acid value 20, mass fraction 99%) and diglyme in a mass ratio of 1:0.7 to obtain alkyd resin diglyme solution;

[0067] 2) The alkyd resin diethylene glycol dimethyl ether solution (including 100 parts of alkyd resin) was heated to 70° C., 20 parts of HDI trimer was added, and reacted for 1.5 hours. Then, 3 parts of hydroxypropyl acrylate were added into the reaction solution, and the reaction was continued for 1 hour to obtain component A.

[0068] 3) Mix 4 parts of hexyl methacrylate, 5 parts of hydroxyethyl acrylate, 1.6 parts of glycidyl methacrylate, 2 parts of epoxy resin E51, 15 parts of methyl methacrylate and 2 parts of azobisisobutyronitrile Mix to obtain Mixture B.

[0069] 4) Mix 1 / 2 of component A, 5 parts of methacrylic acid, 3 parts of butyl methacrylate, 3 parts of hydroxyethyl acrylate, 1.5 parts of glycidyl acrylate, 2 parts of epoxy resin E44, 2 parts of vinyl Trimethoxysilane, 18 parts of styrene an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com