Special resin liquid for hydrophobic melamine foams, and preparation method thereof, and foaming liquid prepared from special resin liquid

A technology for hydrophobic melamine and melamine is applied in the fields of preparation methods and foaming liquids prepared therefrom, and special resin liquids for hydrophobic melamine foams. , Simple and convenient operation, stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of special resin solution

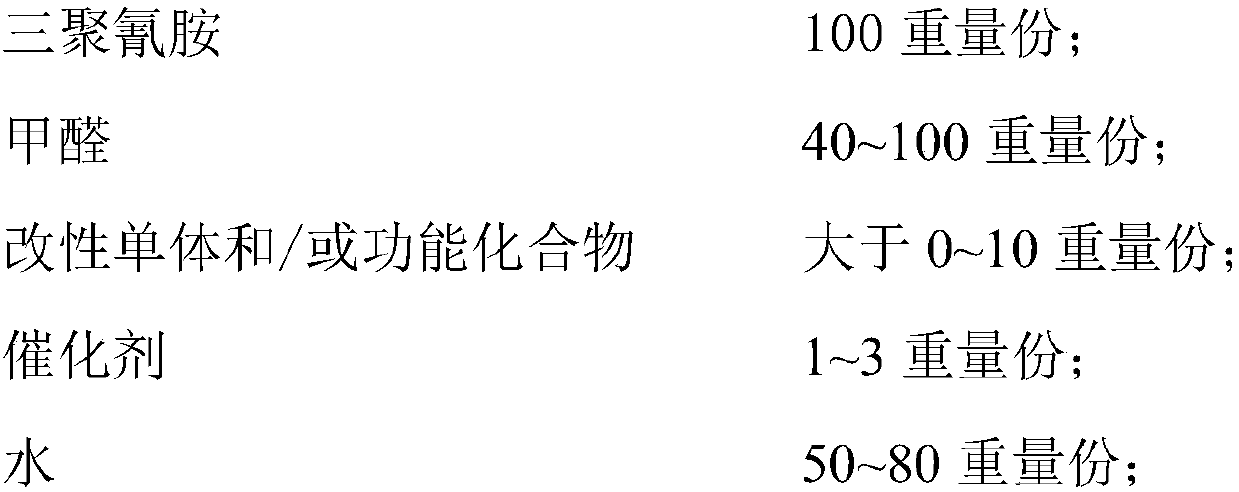

[0051] Raw material ratio:

[0052]

[0053] Add polyethylene glycol monomethyl ether, hexa-carboxyphenoxycyclotriphosphazene, and methyl glycine into the reactor, react at 60-70°C for 40 minutes; then add other raw materials, and react at 980°C for 50-80 minutes to obtain Special resin liquid.

Embodiment 2

[0055] Preparation of special resin solution

[0056] Raw material ratio:

[0057]

[0058] React melamine, formaldehyde, sodium hydroxide, and water at 98°C for 40 minutes, add polyaryloxyphosphazene and ammonium polyphosphate and continue the reaction for 40 minutes to obtain a special resin solution.

Embodiment 3

[0060] Preparation of special resin solution

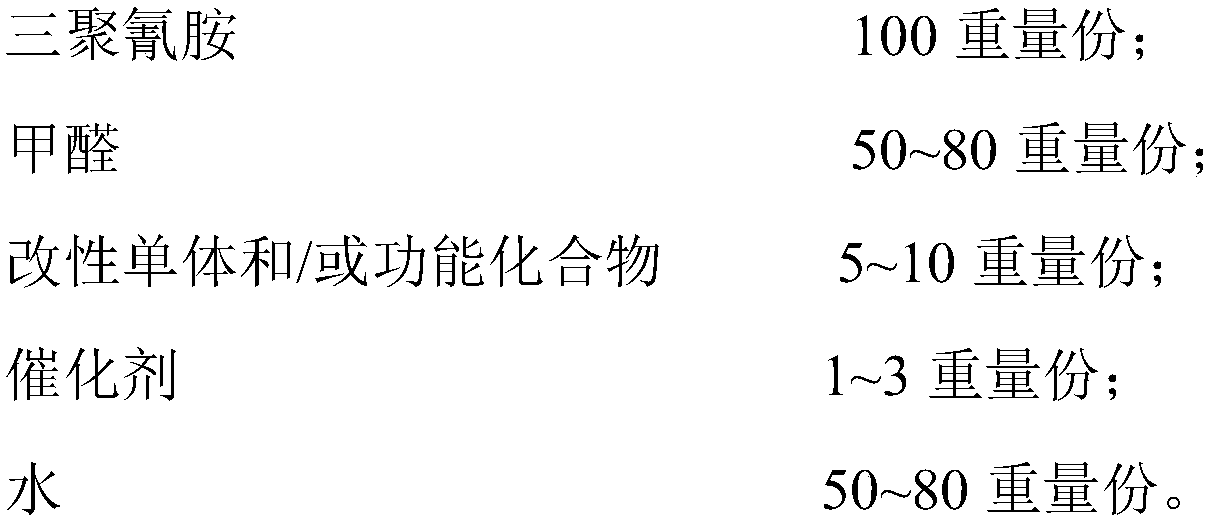

[0061] Raw material ratio:

[0062]

[0063] The above raw materials were reacted at 98°C for 100 minutes to prepare a special resin solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com