Active silicon-loaded additive, preparation method and latex paint with formaldehyde purification function

A technology of active silicon and additives, applied in the field of latex paint, can solve the problems of lack of formaldehyde purification ability and good coating latex paint, and achieve good ability to capture formaldehyde molecules, increase in specific surface area and pore volume, and good VOC purification. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the latex paint with formaldehyde purification function of the present invention is to prepare active silicon first, then use active silicon, tetraammine platinum nitrate and sodium carbonate to prepare the additive 1Na-0.5Pt-Si supported on active silicon; -0.5Pt-Si additive is mixed with other components in latex paint to obtain latex paint. Specifically include the following steps:

[0060] S1, prepare active silicon. The preparation method of active silicon comprises the following steps:

[0061] S1-1. Preparation of ultrafine silica particles:

[0062] First, fly ash with a mass ratio of 1:2 and 8 mol / L NaOH solution were mixed in a three-necked flask, heated to 90 °C in a water bath, and stirred and refluxed at a speed of 300 r / min for 6 h to obtain the solute as NaSiO 3 The solution.

[0063] Next, the solution is suction filtered, the filtrate is collected, and deionized water is used to adjust the concentration of the filtrate to 0...

Embodiment 1

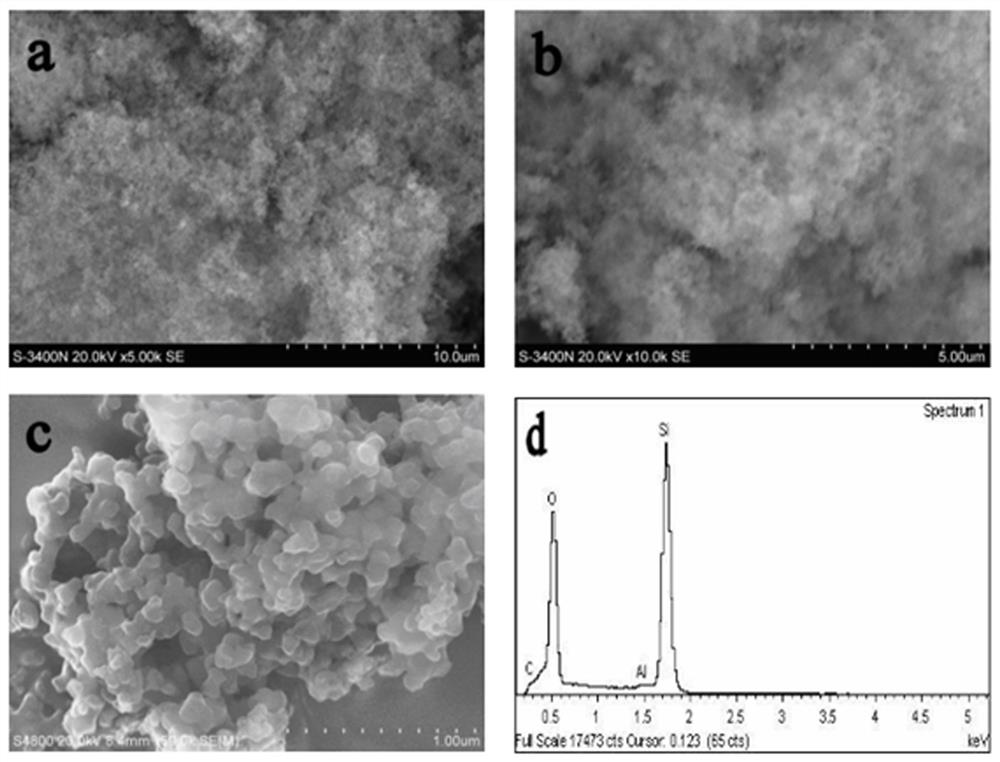

[0088] In this example, the silicon dioxide products obtained by each step of the active silicon in the preparation method of the present invention are respectively investigated, to illustrate that the prepared active silicon has the best microstructure.

[0089] (1) Microstructure of fly ash:

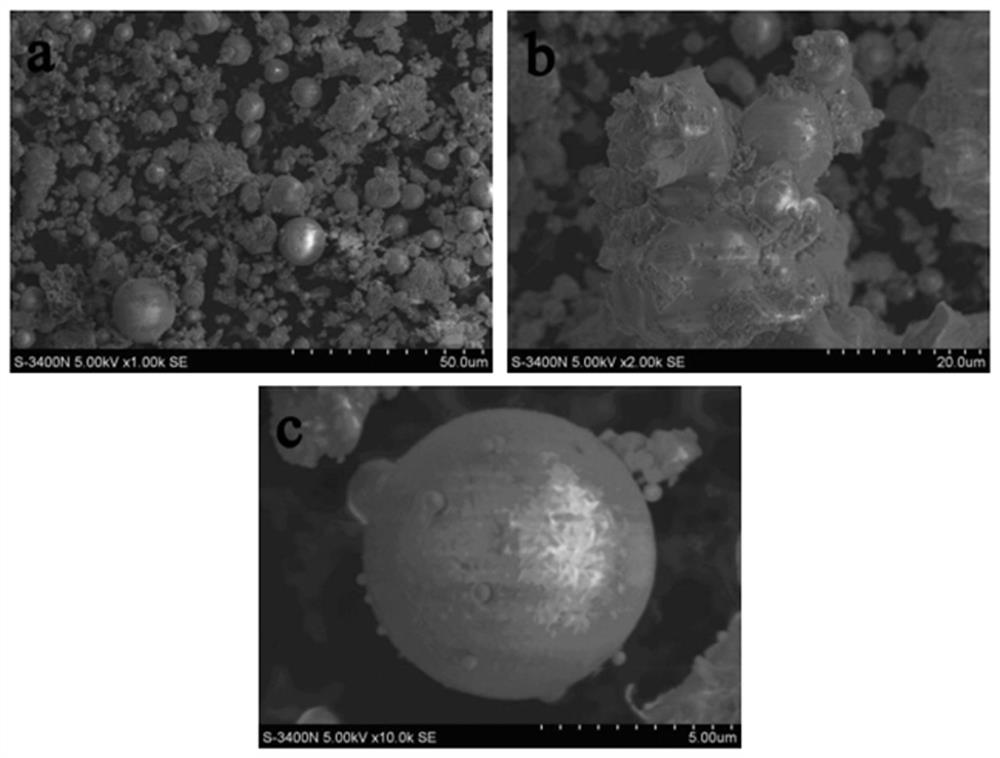

[0090] like figure 1 As shown, the SEM image of the unprocessed fly ash shows that the particle size distribution of the fly ash particles is very non-uniform. The phenomenon of agglomeration between particles is very serious, and there are a large number of hollow microbeads formed by high temperature burning.

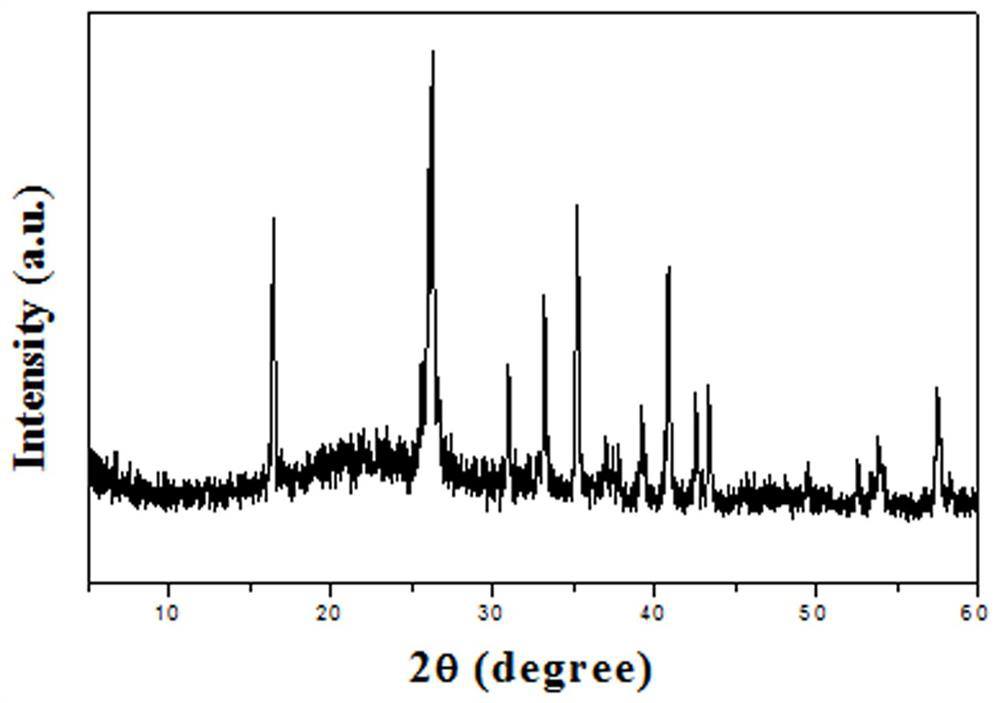

[0091] like figure 2 The structure was characterized by XRD, and strong diffraction peaks appeared at 2θ angles of 16.4°, 26.0°, 31.0°, 33.2°, 35.2°, 37.0°, 39.2°, 40.8°, 41.0° and 42.6°. , by comparing with the standard spectrum of mullite, it can be found that the crystal planes corresponding to these values are (110), (120), (210), (001), (220), (111), (130) ), (201)...

Embodiment 2

[0129] In this example, additives with different loadings of Pt were prepared, and the formaldehyde oxidation performance of each additive was tested.

[0130] According to the preparation method of the present invention, the additives of 2Na-0.1Pt-Si, 1Na-0.5Pt-Si and -2Na-0.5Pt-Si are prepared respectively. The test conditions are 100ppm formaldehyde, 20% oxygen volume content, 35% relative humidity (RH), N 2 For equilibrium gas, the mass space velocity is 100000 mL / (g cat h). Test results such as Figure 17 and 18 shown.

[0131] According to the test results, it can be seen that when there is a relative humidity of 35% in the atmosphere, the 1Na-0.5Pt-Si sample can completely remove 100ppm of formaldehyde at a mass air velocity of 100,000, increasing the space velocity to 200,000, and 2Na-0.5Pt- The formaldehyde removal rate of Si samples remained above 90%. For the 2Na-0.1Pt-Si catalyst, the removal performance of formaldehyde is also relatively poor due to the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com