Gasoline selective hydrodesulfurization bulk phase catalyst, and preparation method and application thereof

A bulk catalyst and hydrodesulfurization technology, applied in the field of petrochemical industry, can solve the problems of high hydrogenation activity, hydrogen consumption, gasoline octane number decline, etc., and achieve the effect of large specific surface area and pore volume, and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

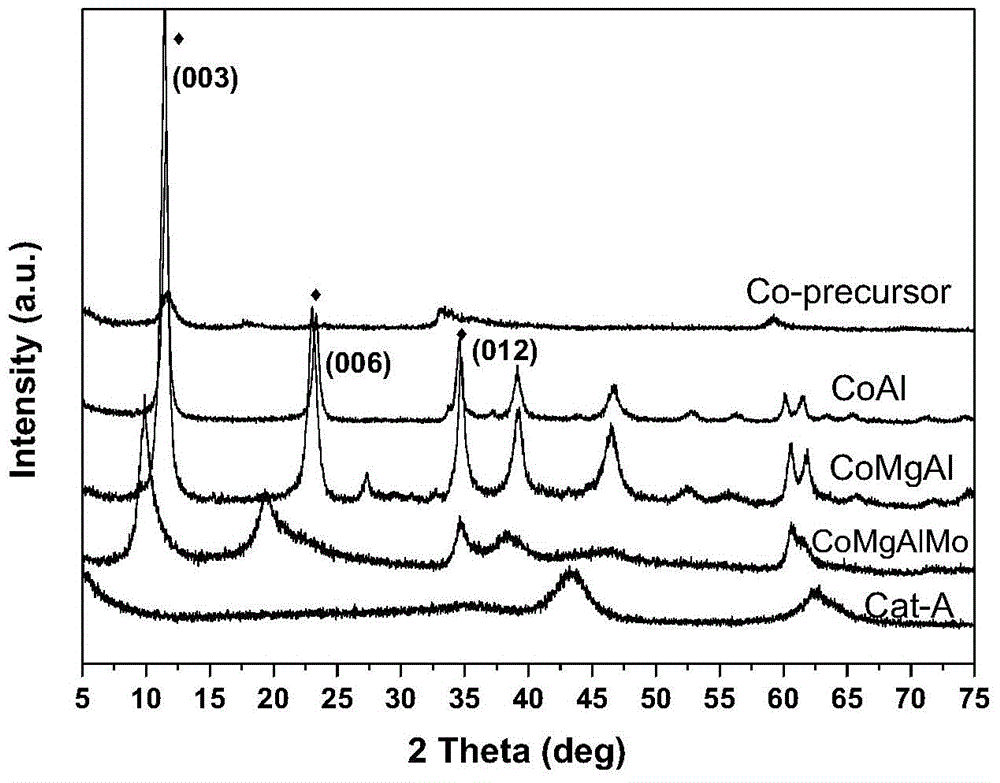

[0055] The present embodiment illustrates the preparation of CoMgAlMo catalyst among the present invention:

[0056] a. Weigh a certain amount of cobalt acetate, magnesium nitrate and aluminum nitrate respectively, wherein Co 2+ 0.04mol, Mg 2+ 0.14mol, Al 3+ 0.05mol, dissolve them in 200ml water to form an aqueous solution, and slowly add K dropwise to it at a temperature of 80°C + K at a concentration of 0.5mol / L 2 CO 3 Solution, adjust pH=11, generate pink precipitate and reflux reaction at this temperature for 3 hours; filter the pink precipitate obtained from the reaction; add the catalyst precursor to 200ml of water to configure a slurry precursor;

[0057] b. Weigh a certain amount of ammonium molybdate, wherein Mo 6+ 0.008mol, they were dissolved in 50ml of water to form a solution, and the solution was heated to the reaction temperature and stirred continuously to form a colorless and transparent solution; subsequently, the slurry precursor in step a was heated to...

Embodiment 2

[0060] The present embodiment illustrates the preparation of CoMgAlMo catalyst among the present invention:

[0061] In addition to using cobalt nitrate (where Co 2+ 0.03mol), aluminum nitrate (where Al 3+ 0.048mol) and ammonium molybdate (where Mo 6+ 0.009mol) to replace cobalt acetate, aluminum nitrate and ammonium molybdate used in embodiment 1, prepare CoMgAlMo catalyst in the same manner as described in embodiment 1, the catalyst of synthesis represents with Cat-B, this Cat- The morphology of catalyst B is similar to Cat-A catalyst. The specific surface area measured by nitrogen adsorption is 145m 2 / g, the pore volume is 0.30ml / g.

Embodiment 3

[0063] The present embodiment illustrates the preparation of CoMgAlMo catalyst in the present invention

[0064] In addition to using cobalt nitrate (where Co 2+ 0.05mol), magnesium nitrate (of which Mg 2+ 0.10mol), aluminum nitrate (where Al 3+ 0.034mol) and ammonium molybdate (where Mo 6+ 0.014mol) to replace cobalt acetate, magnesium nitrate, aluminum nitrate and ammonium molybdate used in embodiment 1, prepare CoMgAlMo catalyst in the same manner as described in embodiment 1, the catalyst of synthesis represents with Cat-C, here The morphology of the Cat-C catalyst is similar to that of the Cat-A catalyst. The specific surface area measured by nitrogen adsorption is 150m 2 / g, the pore volume is 0.27ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com