Method for preparing high performance biomass activated carbon

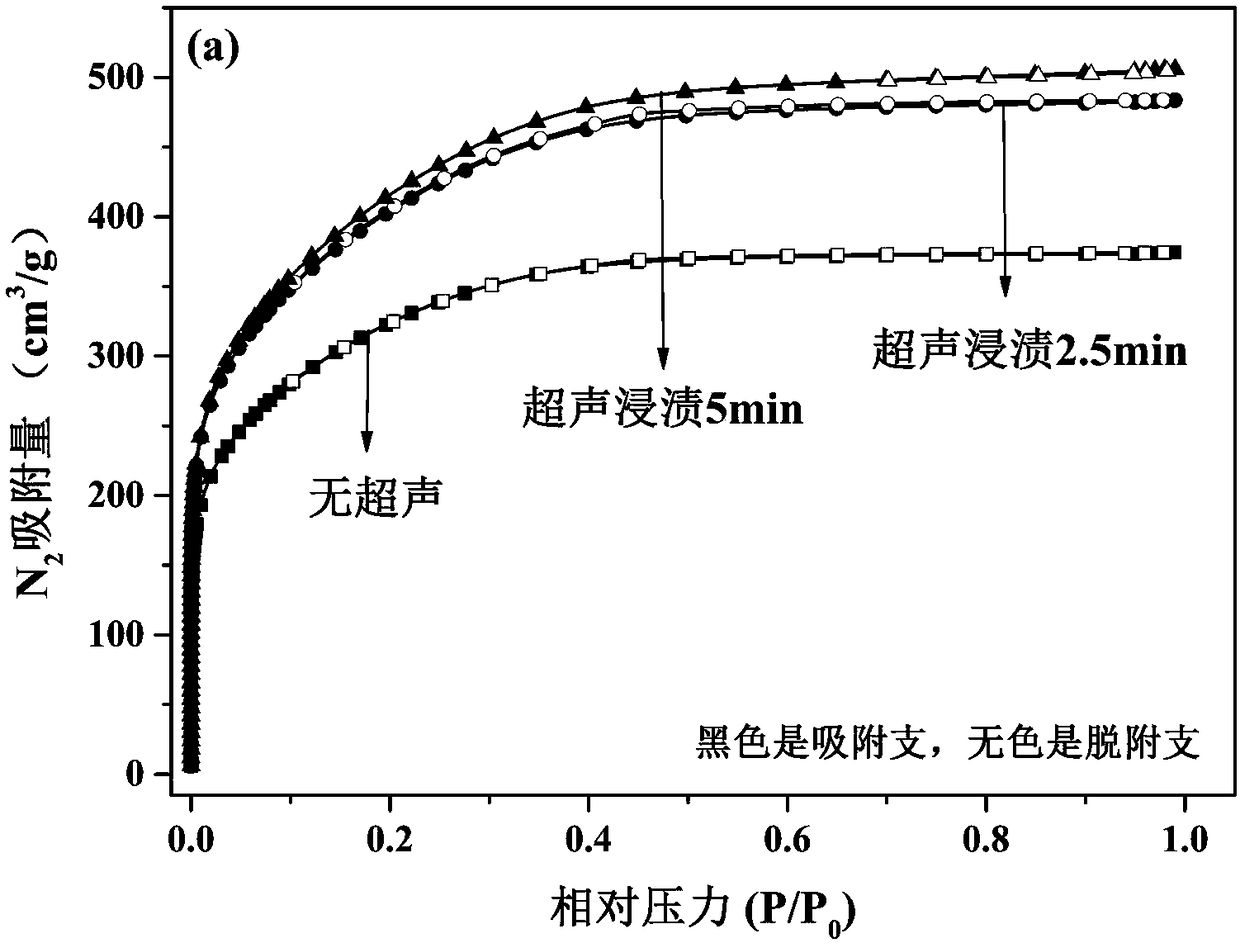

A biomass and activated carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low performance of finished activated carbon, large amount of activator, and long impregnation time, so as to improve adsorption performance and shorten impregnation time Effect of time, increasing pore volume and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for rapidly preparing high-performance activated carbon by ultrasonic enhanced impregnation, which specifically includes the following steps:

[0028] Sieve wood chips with a particle size between 0.22 and 0.90 mm and dry to constant weight. Mix sawdust and 15wt% phosphoric acid at a mass ratio of 1:1.2, treat with immersion ultrasonic (frequency 20kHz, power 540W) for 5 minutes, then let it stand for 40 minutes, move it to an oven and dry it at 110°C for 2.5 hours, then transfer to the tube type In the furnace, nitrogen gas with a flow rate of 400mL / min was continuously introduced, the temperature was raised from 200°C to 425°C at a heating rate of 10°C / min, and the carbon was activated for 2 hours. After cooling to room temperature, the sample obtained by carbon activation is washed with deionized water at 40-50°C until the washing liquid is neutral, and the activated carbon product is obtained after drying. According to the national...

Embodiment 2

[0030] Other experimental parameters of this embodiment are the same as those of Embodiment 1, except that the ultrasonic treatment time is 2.5 min.

Embodiment 3

[0041] This embodiment provides a method for rapidly preparing high-performance activated carbon by ultrasonic enhanced impregnation, which specifically includes the following steps:

[0042] Sieve wood chips with a particle size between 0.22 and 0.90 mm and dry to constant weight. Mix sawdust and 15wt% phosphoric acid at a mass ratio of 1:1.2, treat with tank ultrasonic (frequency 28kHz, power 400W) for 10 minutes, let stand for 5 minutes and then process for 10 minutes, move to an oven and dry at 110°C for 2.5 hours, Transfer to a tube furnace, continuously feed nitrogen at a flow rate of 400mL / min, raise the temperature from 200°C to 425°C at a heating rate of 10°C / min, and conduct carbon activation treatment for 2 hours. After cooling to room temperature, the sample obtained by charcoal activation was washed with deionized water at 40-50°C until the washing liquid was neutral. According to the national standard (GB / T 12496.8-2015), the main indicator - iodine adsorption va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com