High-flash-point safe epoxy micaceous iron oxide intermediate coating and preparation method thereof

A technology of epoxy cloud iron and intermediate coatings, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of flammability, non-environmental protection, poor storage safety, etc., achieve high flash point, improved anti-corrosion performance, good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

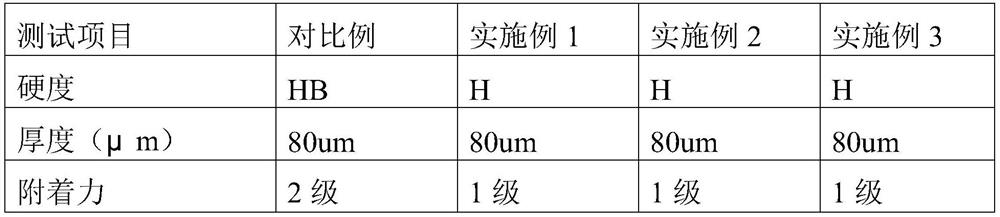

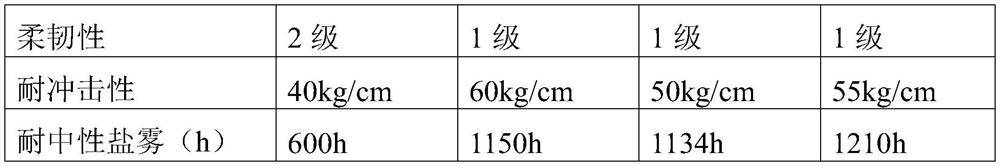

Examples

Embodiment 1

[0028] This example provides a high flash point safe epoxy micaceous iron intermediate coating, which includes a paint component and a curing agent component, and in mass percent, the paint component is made from the following raw materials:

[0029] High flash point epoxy resin, 45wt%;

[0030] Ethylene glycol butyl ether acetate, 8wt%;

[0032] Organic bentonite, 0.8wt%;

[0033] Talc, 15wt%;

[0034] Mica iron oxide, 30.9wt%;

[0035] The hardener component is made from the following raw materials:

[0036] Ethylene glycol butyl ether acetate, 27wt%;

[0037] Phenolic ammonia, 20wt%;

[0038] High flash point epoxy resin, 8wt%;

[0039] Modified polyamide 45wt%.

[0040] Correspondingly, another technical problem to be solved in the present invention is to provide a preparation method of a high flash point safe epoxy micaceous iron intermediate coating.

[0041] As far as the preparation method is concerned, the preparation method of...

Embodiment 2

[0050] This example provides a high flash point safe epoxy micaceous iron intermediate coating, which includes a paint component and a curing agent component, and in mass percent, the paint component is made from the following raw materials:

[0051] High flash point epoxy resin, 35wt%;

[0052] Ethylene glycol butyl ether acetate, 15wt%;

[0054] Organic bentonite, 0.1wt%;

[0055] Talc, 20wt%;

[0056] Mica iron oxide, 28.9wt%;

[0057] The hardener component is made from the following raw materials:

[0058] Ethylene glycol butyl ether acetate, 50wt%;

[0059] Phenolic ammonia, 15wt%;

[0060] High flash point epoxy resin, 10wt%;

[0061] Modified polyamide 25wt%.

[0062] Correspondingly, another technical problem to be solved in the present invention is to provide a preparation method of a high flash point safe epoxy micaceous iron intermediate coating.

[0063] As far as the preparation method is concerned, the preparation method of...

Embodiment 3

[0072]This example provides a high flash point safe epoxy micaceous iron intermediate coating, which includes a paint component and a curing agent component, and in mass percent, the paint component is made from the following raw materials:

[0073] High flash point epoxy resin, 15wt%;

[0074] Ethylene glycol butyl ether acetate, 23wt%;

[0075] Polyamide wax, 1wt%;

[0076] Organic bentonite, 1wt%;

[0077] Talc, 30wt%;

[0078] Mica iron oxide, 30wt%;

[0079] The hardener component is made from the following raw materials:

[0080] Ethylene glycol butyl ether acetate, 20wt%;

[0081] Phenolic ammonia, 20wt%;

[0082] High flash point epoxy resin, 10wt%;

[0083] Modified polyamide 50wt%.

[0084] Correspondingly, another technical problem to be solved in the present invention is to provide a preparation method of a high flash point safe epoxy micaceous iron intermediate coating.

[0085] As far as the preparation method is concerned, the preparation method of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com