Method and system for producing clean diesel oil from waste plastic oil and/or waste tire oil

A technology for waste tires and waste plastic oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc., can solve the problems of short processing cycle, etc., and achieve the effect of low cost, extended operation cycle and good impurity removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

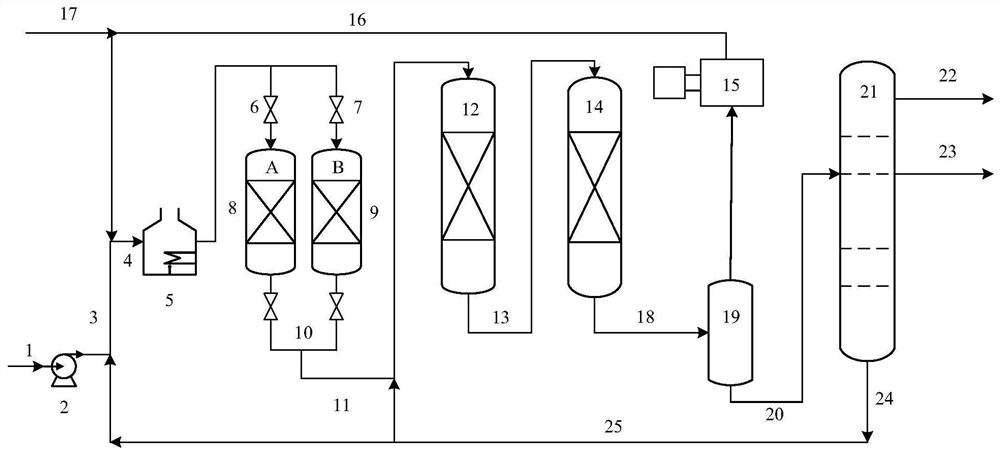

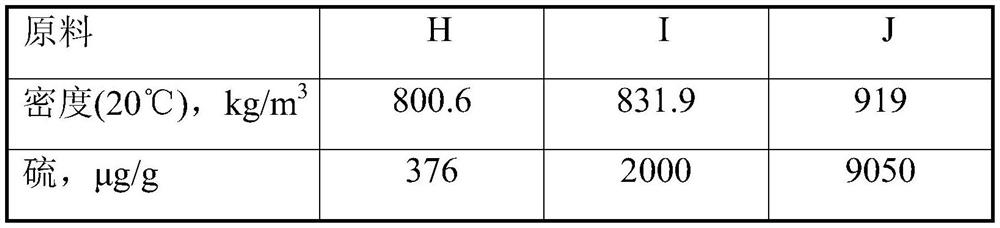

[0079] The raw material of waste plastic oil enters the decontamination reactor and contacts with the waste and old hydrogenation catalyst in the presence of hydrogen, and carries out decontamination reaction under decontamination reaction conditions, and the obtained reaction effluent enters the hydrotreating reactor and contacts with the hydrotreating catalyst, The hydrotreating reaction is carried out under the hydrotreating reaction conditions, the reaction effluent of the hydrotreating reactor enters the hydrocracking reactor and is contacted with the hydrocracking catalyst, the hydrocracking reaction is carried out under the hydrocracking reaction conditions, and the hydrocracking reaction is carried out. After the reaction effluent of the cracking reactor is subjected to gas-liquid separation by the high-pressure separator, a gas-phase stream and a liquid-phase stream are obtained, and the obtained liquid-phase stream enters a fractionation tower for fractionation to obta...

Embodiment 4-5

[0082] The raw materials of waste plastic oil and waste tire oil enter the de-purification reactor and contact the waste hydrogenation catalyst in the presence of hydrogen, and carry out de-impurification reaction under de-purification reaction conditions. The hydrotreating catalyst is contacted, and the hydrotreating reaction is carried out under the hydrotreating reaction conditions, and the reaction effluent of the hydrotreating reactor enters the hydrocracking reactor and contacts with the hydrocracking catalyst, and the hydrotreating reaction is carried out under the hydrocracking reaction conditions. In the cracking reaction, the reaction effluent of the hydrocracking reactor is subjected to gas-liquid separation by a high-pressure separator to obtain a gas-phase stream and a liquid-phase stream, and the obtained liquid-phase stream enters a fractionation tower for fractionation to obtain gasoline fractions, diesel fractions and tail oil fractions , all the tail oil fract...

Embodiment 6

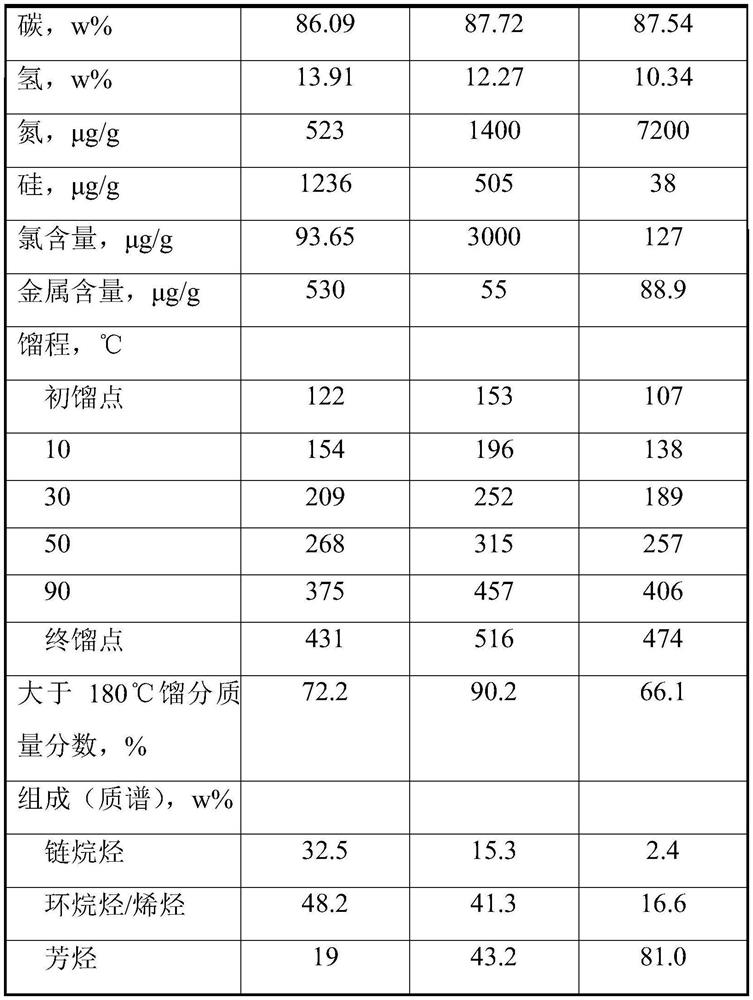

[0099] In the present embodiment, two parallel fixed-bed hydrogenation reactors 1 and 2 are arranged in the impurity removal unit, and the raw material I is used as the feed. The catalyst loading situation, the impurity removal reaction conditions and the reaction results are listed in Table 6.

[0100] When the reactor 1 runs for 250 hours, the silicon content of the liquid phase material in the reaction effluent is greater than 1 μg / g. At this time, the reactor 2 is switched to carry out the decontamination reaction, and the silicon content of the liquid phase material is reduced to less than 1 μg / g. The catalyst is replaced in the reactor 1, and this cycle realizes long-term operation.

[0101] Table 6

[0102]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com