High-power compact electro-hydraulic wind generating set assembly

A wind turbine, compact technology, applied in the direction of wind motor combination, wind engine, engine, etc., can solve the problems of mechanical friction loss, difficulty in ensuring accuracy, and reduction of maintenance workload, so as to reduce the weight of the nacelle, achieve low price and network, installation cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

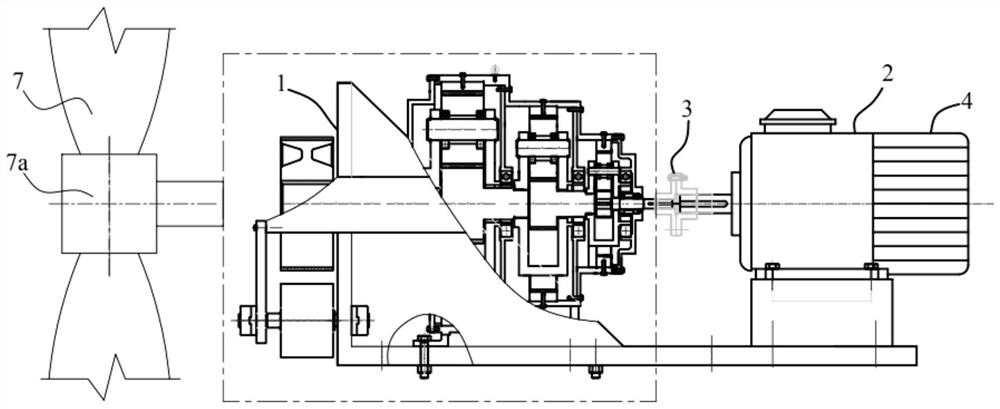

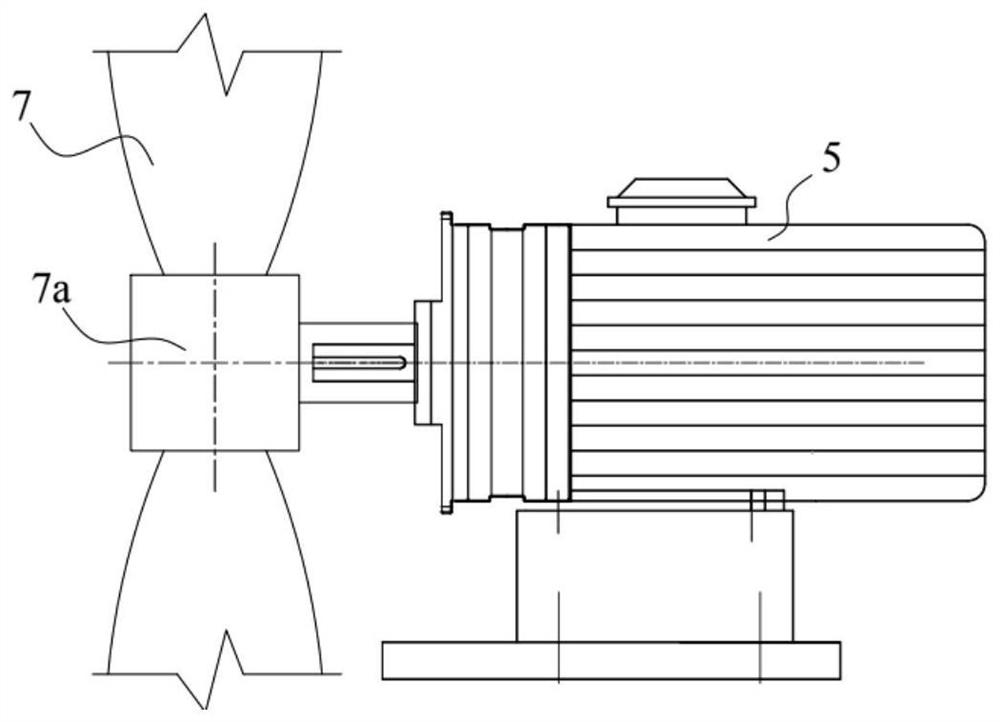

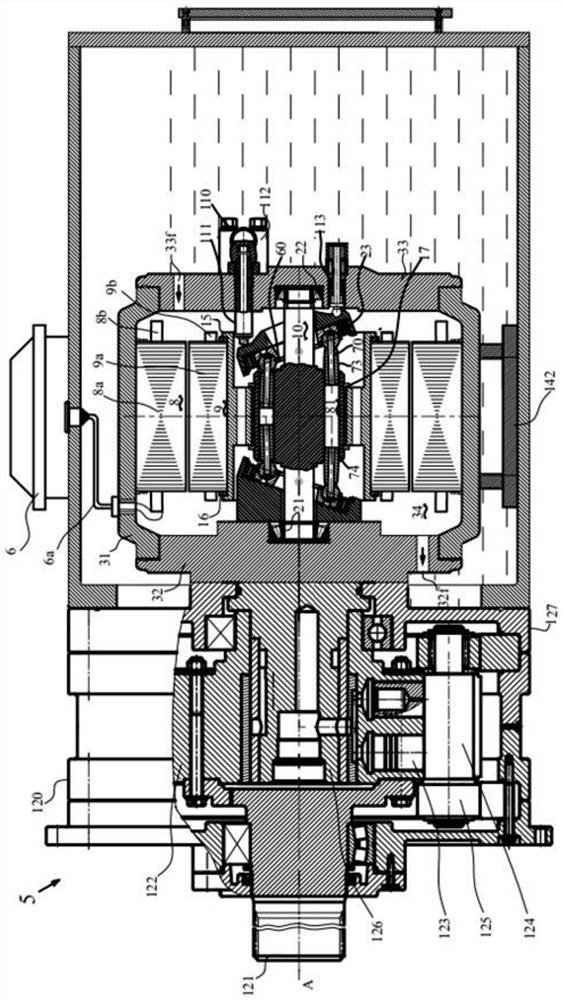

[0061] like Figures 2 to 5 As shown, it is a preferred embodiment of the high-power compact electro-hydraulic wind generator set 5 of the present invention. In the preferred embodiment shown, the electro-hydraulic wind generator set 5 is a shaft-supported structure, including an impeller assembly, hydraulic The pump assembly, the fuel tank, and the electro-hydraulic integrated machine assembly accommodated in the cavity 141 of the fuel tank casing, the electro-hydraulic integrated machine assembly including the generator casing assembly and the casing cavity 34 accommodated in the generator casing assembly Inside the generator assembly and hydraulic motor assembly, the generator assembly includes a rotor assembly 9 and a stator assembly 8, the hydraulic motor assembly includes a distribution sliding plate pair and a plunger pair, the hydraulic pump assembly is from the oil tank housing. The cavity 141 and / or the housing cavity 34 of the generator absorbs oil, the impeller ass...

Embodiment 2

[0094] like Figure 13 As shown, the difference from Embodiment 1 is the number and structure of the cylinders in the hydraulic motor assembly.

[0095] Specifically, the hydraulic motor assembly includes two cylinders 80 , the cylinders 80 have a cylindrical configuration with a circular cross-section in the radial direction, and are accommodated in the cavity of the rotating drum 11 , and the cylinders 80 have There are a plurality of plunger holes 81 evenly distributed in the circumferential direction of the central axis of the cylinder body and a spindle assembly hole for accommodating the main shaft 10 at the center. Preferably, the number of the plunger holes 81 is generally set to 7 or 9.

[0096] Further, the main shaft 10 passes through the main shaft assembly hole of the cylinder block 80 and is connected to the cylinder block 80 by means of connecting keys on the outer peripheral surface of the shaft. 10 on. The central part of the main shaft 10 is provided with ...

Embodiment 3

[0099] like Figure 15 As shown, the difference from Embodiment 1 is that the oil suction path of the hydraulic pump assembly is different.

[0100] Specifically, the front end cover 32 in the generator housing assembly is further provided with a front end cover oil inlet channel 32a, one end of the front end cover oil inlet channel 32a is open to the casing cavity 34, and the other end is connected to the hydraulic pump assembly. The shaft low pressure port 126a is communicated with, the rear end cover 33 is provided with a rear end cover oil inlet 33a, one end of the rear end cover oil inlet 33a is communicated with the tank housing cavity 141, and the other end is connected with the housing cavity 34 .

[0101] It can be seen from this that the oil suction path of the hydraulic pump is as follows. Oil is sucked through the three friction pairs of the hydraulic motor assembly, the stator assembly and the rotor assembly of the generator assembly, and through the oil inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com