Premixing low-nitrogen gas boiler

A gas-fired boiler and premixing technology, applied in the direction of burners, combustion types, combustion methods, etc., can solve the problems that cannot be applied in actual production, and the cost is difficult to popularize and apply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

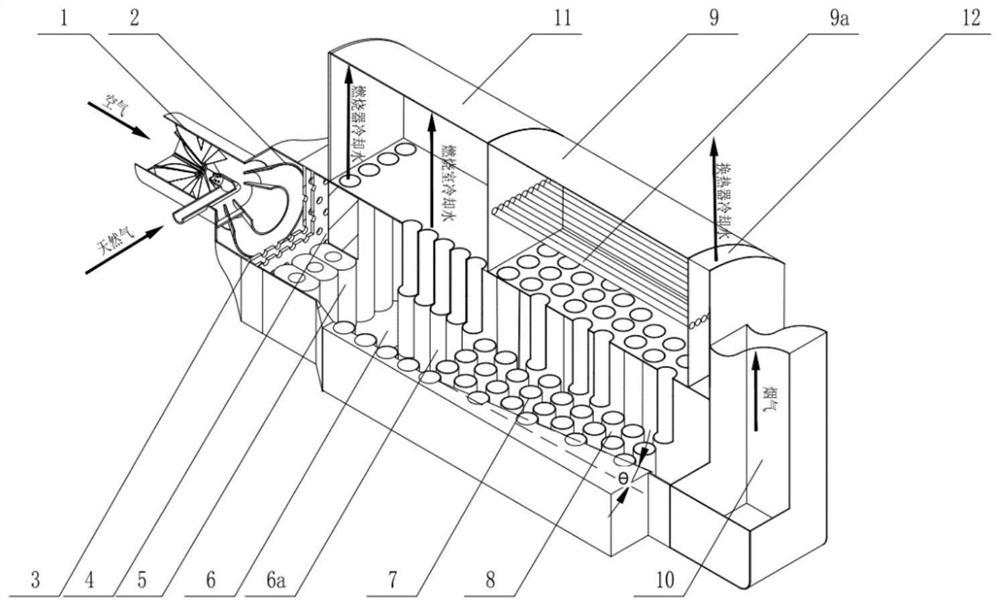

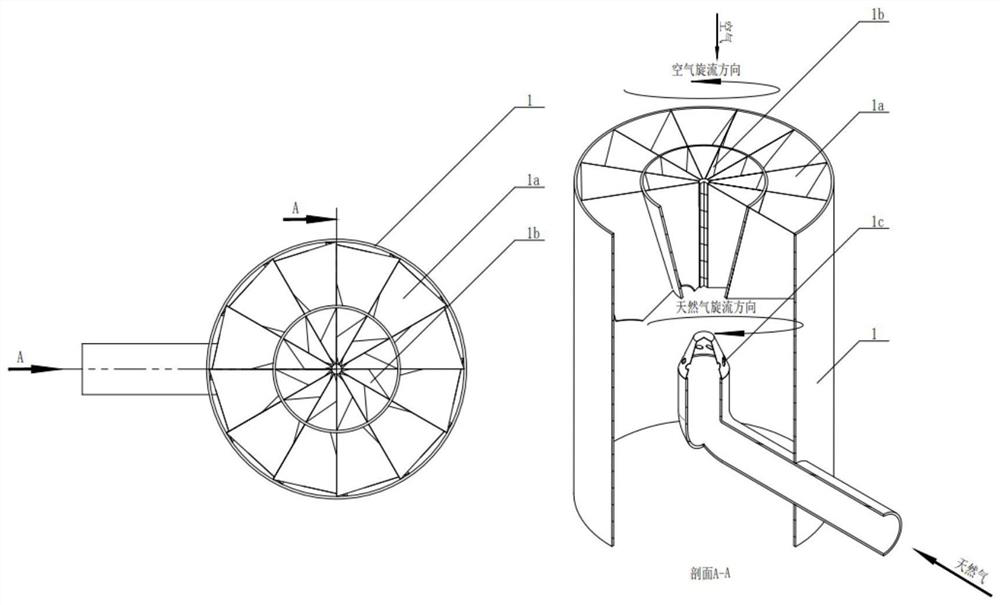

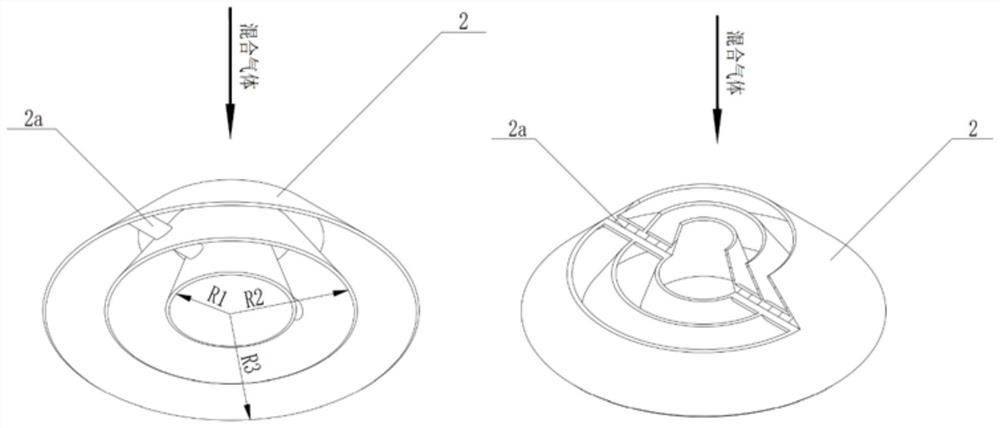

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] refer to Figure 1-Figure 6 For the premixed low-nitrogen gas fired boiler, the countercurrent swirl mixer 1 can realize the hedging mixing of natural gas and air to ensure the uniformity of the mixed gas; temperature and NO x production volume. Its main structure has the counter-current swirl mixer 1 of the present invention, which includes an outer expanding air swirl blade 1a, an inner constricting air swirl blade 1b and a gas swirl structure 1c, which realizes the swirl hedging mixing of natural gas and air; The mixed gas is uniformly mixed after passing through the baffle plate 2, and the "comb" water-cooled burner 5 behind the lower baffle plate 4, the spiral ring rib 5d can increase the turbulence, strengthen the heat exchange effect, and ensure low-temperature combustion; When loaded, the high-temperature flue gas is entrained and ignited st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com