Method for detecting durability of prefabricated building sealant in extreme environment

A technology of extreme environment and detection method, applied in the direction of applying stable tension/pressure to test material strength, measuring device, adopting mechanical device, etc., can solve the problem of not considering the comprehensive effect of sealants, etc., and achieve easy detection method and simple structure Reasonable, accurate and reliable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention provides a method for detecting the durability of prefabricated building sealants in extreme environments, including:

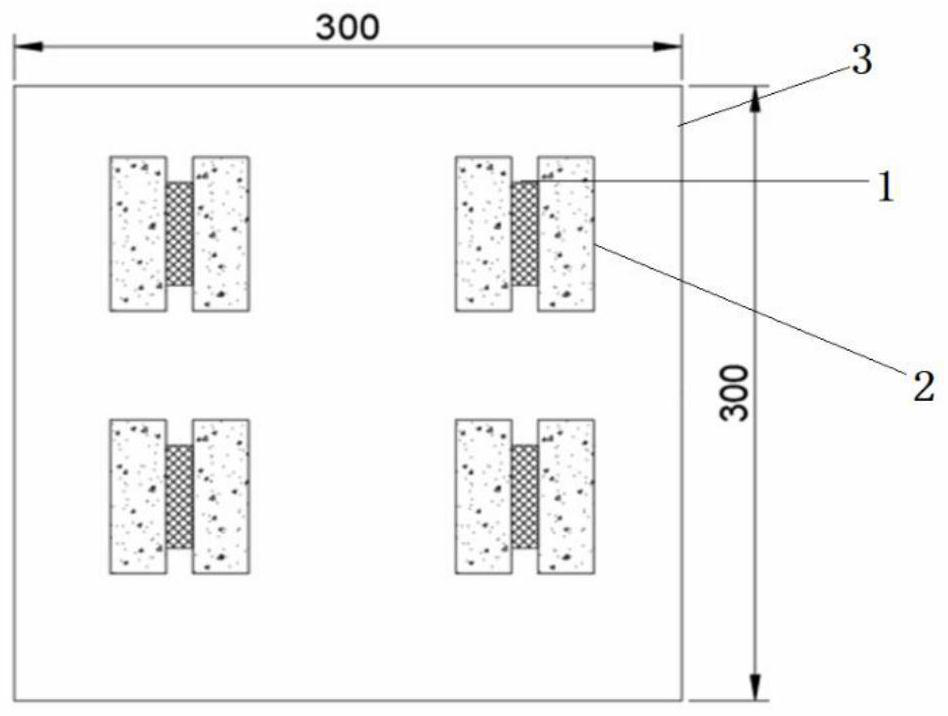

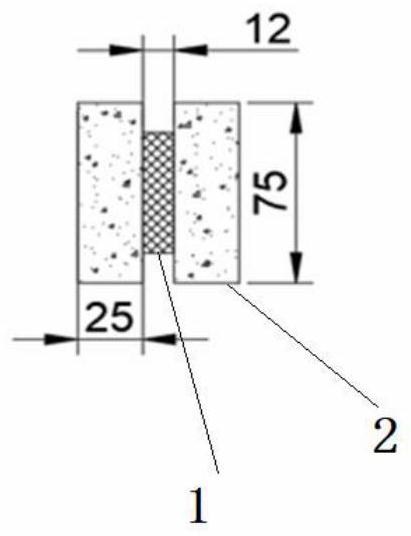

[0029] (1) The sealant to be tested is made into an I-shaped test piece according to the requirements of "Sealant for Concrete Building Joints" JC / T 881, the base material is cement mortar board, and the number of test pieces is made according to 4 pieces / group. 8 groups of test pieces; all test pieces use matching primer;

[0030] (2) The above-mentioned specimens were cured under standard conditions for 28 days. After curing, each group of specimens was drenched with water until saturated with water, and then embedded in a 300×300×30mm XPS foam insulation board to make a test specimen to be tested. like structure;

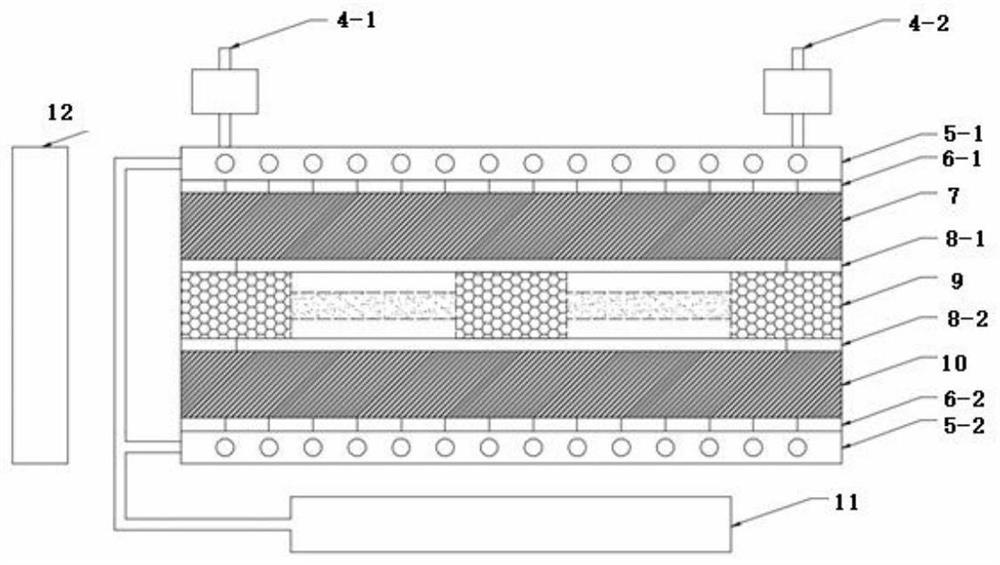

[0031] (3) Put the above-mentioned sample structure to be tested into the thermal conductivity meter, set the temperature of the cold plate to -20°C and the temperature of the hot plate to 20°C to simulate the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com